Harsh processing of tungsten carbide material can be completed by tools like diamond grinding wheels. Besides that, many modern processing technologies are invented and developed currently for purpose of obtaining products of complicated shape in less processing time, such as EDM, supersonic processing, electrolytic processing, electron beam processing and lazer processing.

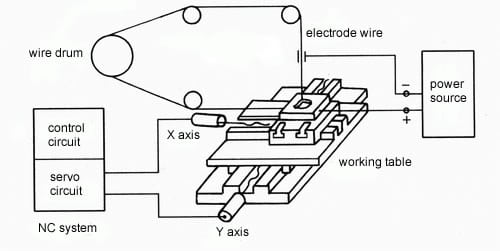

EDM is focused on in this article, known as wire electrical discharge machining to cutting off spare parts with two electrodes made of metallic carbide or metal in a designed circuit that leads the machining path. It’s firstly noticed and observed by Joseph Preistly in 1770. Then In the 1940’s two Soviet researchers, the Lazarenkos’, are the primary scientists to find this technic practical in processing hard-to-machine materials. Then the first batch of EDM machines for manufacturing dies made from hardened steel ensued in 60’ 20th century. Till 1974, A wire-cut EDM machine using the CNC drawing plotter was produced, which can handle processing task demanding greater accuracy.

Features of EDM

Nowadays, machining work piece up to 16″ thick, EDM can ensure its accuracy of +/-0.002mm. Nearly no burrs generated. Since no any cutting forces and stresses exist in this process, wire EDM is ideal for delicate parts by keeping them away from flaws like distortion. Apart from that, tools and parts are machined after heat treatment, so dimensional accuracy is not affected by any heat treat distortion.

Processing condition and range of application of EDM.

a.What needs EDM:

1.In complex shapes

2.Demanding high accurate tolerances

3.Delicate, precious,or weak materials

b.processing condition

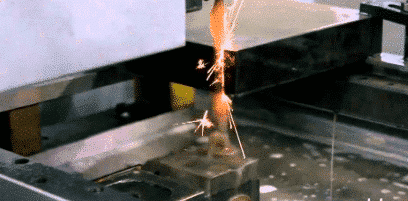

There must be a gap between electrodes and work piece’s surface and the width of it is subject to working voltage and processing quantity. When a WEDM machine is machining a workpiece , it must be carried out in a liquid medium with certain insulation properties, such as kerosene, saponified oil, deionized water, etc. It is required to teach high insulation to facilitate the generation of pulsed spark discharge, liquid The medium also has the effect of eliminating the electrolytic corrosion products and cooling electrodes in the gap. The molybdenum wire and the workpiece are kept at a certain gap between the processed surfaces. If the gap is too large, the voltage between the electrodes cannot penetrate the interpolar medium, and the spark discharge cannot be generated. If the gap is too small, the short-circuit connection is easily formed, and the electric power cannot be generated. The pulse power supply must be used, that is, the spark discharge must be pulsed and intermittent. During the pulse interval, the gap medium is de-ionized so that the next pulse can break through the discharge between the two poles.

c. Application range of wire cutting processing

(1)It is possible to process electrodes for electric spark forming processing, electrodes for perforating processing, and electrodes for taper cavities. In addition, electrode materials such as copper tungsten and silver tungsten alloy are particularly economical to be wire-cut.

(2)When a new product is trial-produced, the manufacturing cycle can be greatly shortened and the cost can be reduced because no additional mold is required. It is also convenient to modify the design and change the processing program.

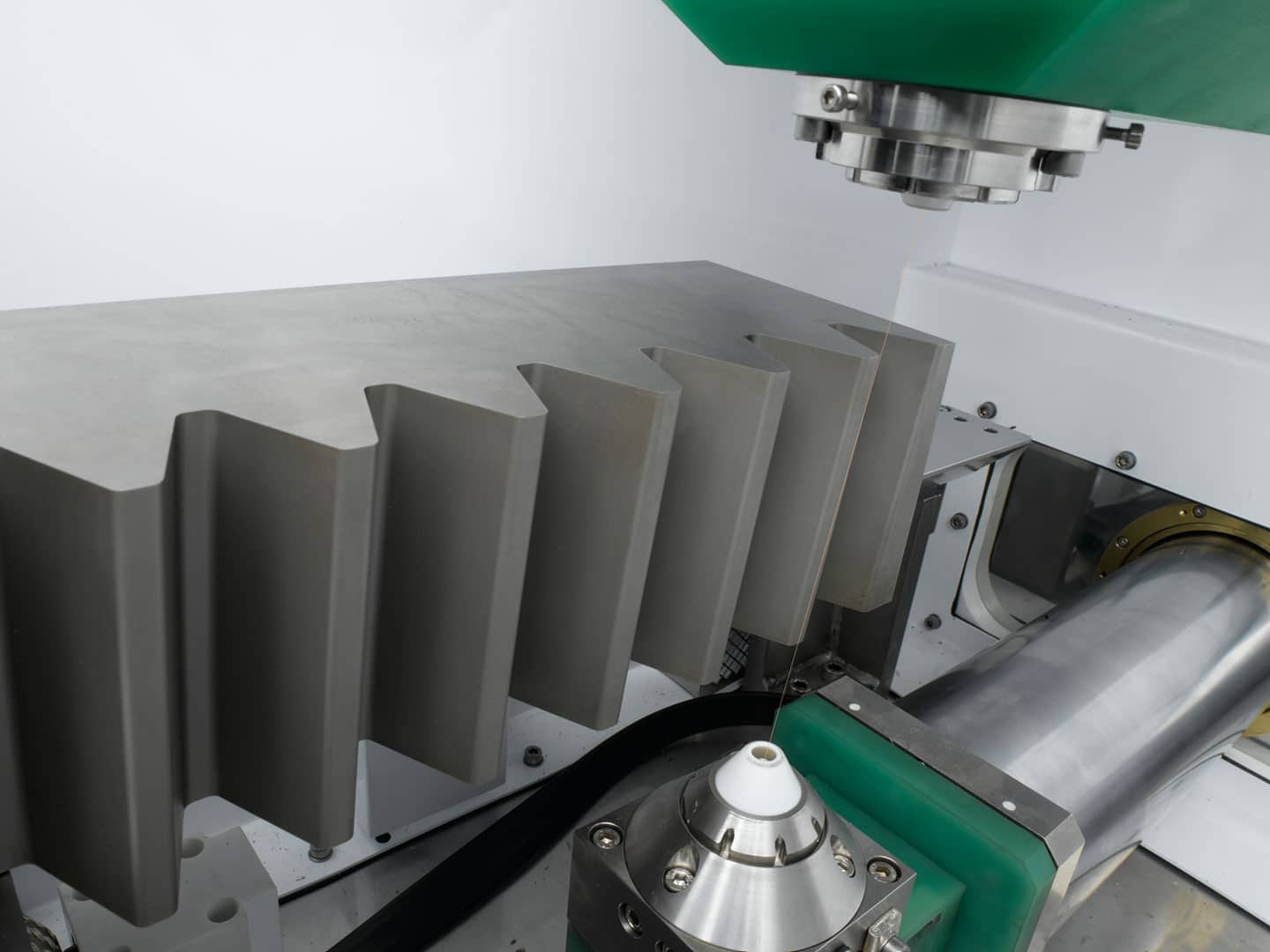

(3)Machining mold parts, EDM wire cutting processing is mainly used in the processing of die, extrusion die, plastic die, EDM cavity die. Due to the rapid improvement of the speed and precision of WEDM, it has reached the point of coordinate grinding machine. The extent of competition. Therefore, the precision grinding and other processes in some industrialized countries have been replaced by EDM and WEDM.

Processing example

Wire EDM uses a wire to cut the programmed contour in the workpiece. Extrusion die and blanking punch are often machined by wire cutting. Cutting always runs through the entire workpiece. To start machining, you must first drill a hole in the workpiece or start at the edge. In the machining area, each discharge creates a pit on the workpiece and impacts the tool. The wire can be tilted so that tapered or differently shaped parts can be made at the top and bottom. There is no mechanical contact between the electrode and the workpiece (see above). The wires are usually made of brass or layered copper and have a diameter between 0.1 and 0.3 mm.

Depending on the accuracy and surface finish required, a part is either cut once or roughed and bristled. In one cut, the wire desirably passes through a solid portion that will drop a slug or debris upon completion. This will provide enough accuracy for some jobs, but in most cases, skimming is necessary. Slag cutting refers to the position of the steel wire passing through the rough surface again at a lower power setting and low pressure flushing. Depending on the accuracy and surface finish required, there can be one to nine slag passes. There are usually only two ski runs. A skim channel can remove up to 0.002 inches of material, or only 0.0001 inches of material. During roughing (ie, the first cut), water is forced into the cut at high pressure to provide sufficient cooling and to eliminate erosion particles as quickly as possible. During the slag (precise/fine cut) process, the water gently flows through the cautery to prevent the wire from deflecting.