ATC is the abbreviation of auto tool changer. It is a device that provides tool storage and tool change requirements required in the process of automatic machining. Its automatic tool changing mechanism and ATC, which can store multiple tools, have changed the traditional human-oriented production mode. With the control of computer program, various processing requirements can be completed, such as milling, drilling, boring, tapping, etc., greatly shortening the processing time and reducing the production cost, which is the biggest feature of ATC system.

Composition of ATC

ATC mainly provides the tool storage position, and can correctly select the tool for positioning according to the program control, so as to carry out tool exchange; The tool change mechanism is used to perform tool exchange. ATC must exist at the same time as the tool change mechanism. If there is no ATC, the tools required for processing cannot be stored in advance; If there is no tool change mechanism, the tools required for machining cannot be changed in sequence from ATC, and the purpose of reducing non cutting time is lost. The two complement each other in function and application.

Types and functions of ATC

In the automatic tool change device, ATC is one of the most important components. ATC is used to store machining tools and auxiliary tools. Its capacity, layout and specific structure have a great impact on the design of CNC machine tools. 2. ATC form ATC can be designed into various forms according to ATC capacity and tool taking mode. Common forms are as follows.

Straight line ATC

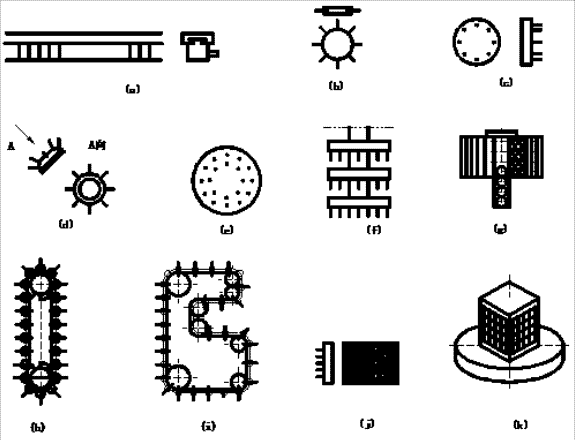

This sort of ATC tools are arranged in a straight line in ATC, as shown in Figure a. Its structure is simple, ATC capacity is small, and it can generally accommodate 8 ~ 12 cutters, so it is rarely used. This form is commonly seen in automatic tool changing CNC lathes and has also been used in CNC drilling machines.

Disc cutter

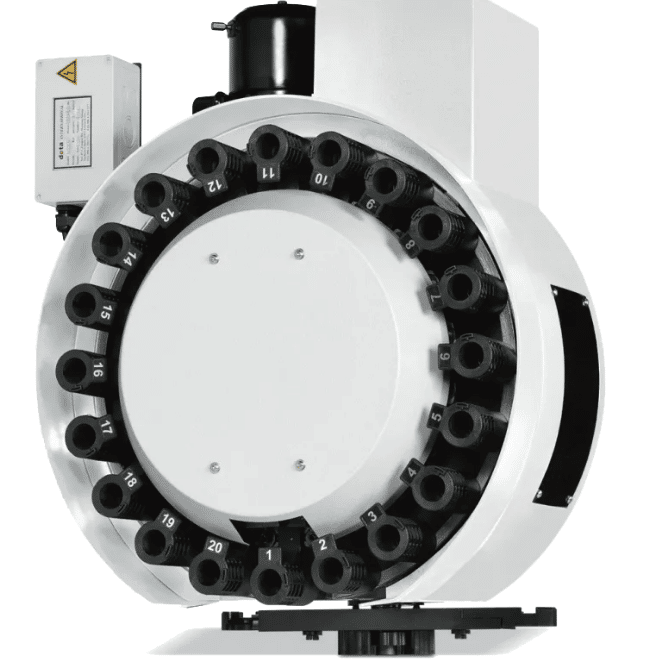

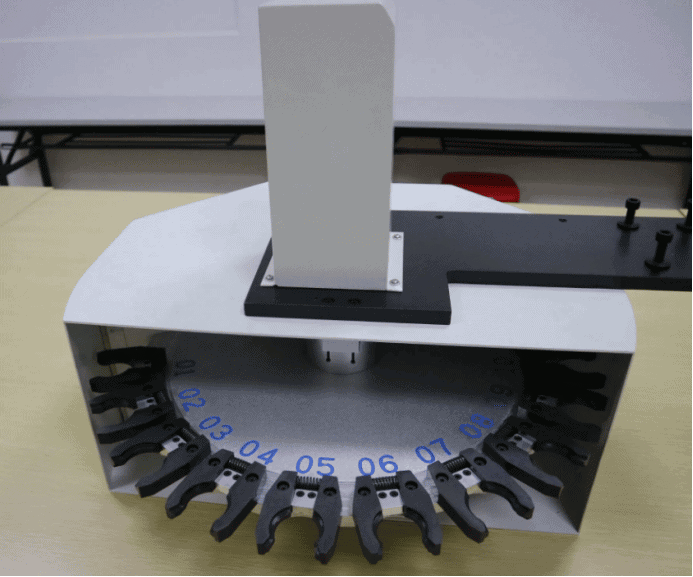

There are 6 ~ 8 cutters and 50 ~ 60 cutters stored in this form, among which there are many forms.

In the ATC as shown in Figure B, the tool radial layout occupies a large space, and the ATC position is limited. It is generally placed at the upper end of the machine tool column. Its tool change time is short, making the whole tool change device simpler.

2) In the ATC as shown in Figure C, the tool axial layout is usually placed on the side of the spindle. ATC axis line can be placed vertically or horizontally, which is widely used

3) In the ATC as shown in Figure D, the cutter is arranged in an umbrella shape at a certain angle (less than 90o) with the ATC axis line. The ATC position can be arranged according to the overall layout requirements of the machine tool. It is mostly placed on the upper end of the column, and the ATC capacity should not be too large.

Chain ATC

The above three types of disc ATC are commonly used. The maximum tool storage capacity is 50 ~ 60. If the tool storage capacity is too large, the structure size is huge and incompatible with the layout of the machine tool.

In order to further expand the tool storage, some machine tools use the disc ATC with multiple circles of distributed tools, as shown in Figure E; Multilayer disc ATC, as shown in Figure f; Multi row disc ATC, as shown in Figure G. Multi row disc ATC has 4 knives in each row, which can be replaced in the whole row. The last three ATC forms are rarely used.

Chain ATC is a common form. The ATC cutterbed is fixed on the ring link. Single row chain ATC is commonly used, as shown in Figure H. This ATC uses an extended chain, which can be folded and rewound to improve the space utilization and further increase the tool storage, as shown in Figure I. The chain ATC has compact structure and large ATC capacity. The shape of the link can be made into various shapes according to the layout of the machine tool. At the same time, the tool change position can also be highlighted to facilitate tool change. Within a certain range, when the number of tools needs to be increased, the length of the chain can be increased without increasing the diameter of the sprocket.

Therefore, the circumferential speed of the sprocket (linear speed of the chain) may not be increased, and the increase of ATC motion inertia may not be considered. These provide a lot of convenience for the design and manufacture of series ATC. Generally, when the number of cutters is 30 ~ 120, chain ATC is usually used.

Other ATC

There are many forms of ATC, especially the lattice ATC. Figure J shows the single-sided type. Due to the inflexible layout, ATC is usually placed on the workbench and is rarely used. Figure K shows a multi-faceted type. In order to reduce the tool change time, the tool change manipulator usually takes out the tool to be replaced in advance by using the previous tool to process the workpiece (the equipped CNC system should have this function). The ATC occupies a small area and has a compact structure. It can accommodate a large number of cutters in the same space. However, because of its complex tool selection and pick-up actions, it is now less used in single machine machining centers and more used in FMS (flexible manufacturing system) centralized tool supply system.

summary

ATC capacity the more tools in ATC, the better. Too much capacity will increase the size and floor area of ATC and increase the tool selection time. The capacity of ATC shall first consider the needs of processing technology. According to the statistics of the number of tools required by the vertical machining center mainly for drilling and milling, draw the curve shown in the following figure. The curve shows that 70% of the drilling process can be completed with 10 hole machining cutters and 90% of the milling process can be completed with four milling cutters.

It can be seen that more than 70% of drilling and milling can be completed with 14 cutters. If we count all the processes of the workpiece to be processed, the result is that most (more than 80%) of the workpieces only need 40 cutters to complete the whole processing process. Therefore, from the perspective of use, the capacity of ATC is generally taken as 10 ~ 40. Blindly increasing the ATC capacity will reduce the utilization rate of ATC, make the structure too complex and cause great waste.