At present, the regions in China that are most active in the recycling and regeneration of waste cemented carbide include Jinan City in Shandong Province, Qinghe County in Hebei Province, Mudanjiang City in Heilongjiang Province, and Zhuzhou City and Changsha City in Hunan Province.

Economic Benefits of Recycling Waste Carbide

Tungsten is the main component of cemented carbide, accounting for almost 50% of the total tungsten usage in its production, with China’s share being around 40%. Relevant data indicate that the demand for cemented carbide in various countries will rise significantly from the end of this century to the beginning of the next. It is estimated that by 2000, the demand could reach 40,000 tons, about 1.5 times the current production. However, tungsten is a rare element, with a crustal abundance of only 1×10?%, and the currently exploitable tungsten is only sufficient for 50 years.

Although China is a major producer of tungsten, both its reserves and recoverable quantities are showing a decreasing trend. Therefore, the rational utilization and recycling of tungsten resources should be placed on our agenda as an urgent issue to be seriously studied. Assuming that China’s recycling rate of waste alloy increases from 10% to 20%, it would mean an annual increase of several hundred tons of tungsten production. This would require the provision of several thousand tons of tungsten concentrate (containing 65% WO?) as raw material, equivalent to the tungsten content of 220,000 tons of raw ore (with a grade of 0.5% WO?). Thus, vigorously recycling cemented carbide is of great significance for the rational utilization and protection of existing tungsten resources.

Another major component of cemented carbide is cobalt. Due to the lack of cobalt resources in China, a large amount of cobalt needs to be imported annually to meet production needs. At the current level, recycling several hundred tons of cemented carbide in China each year could recover several tens of tons of cobalt, thereby saving a significant amount of foreign exchange for?our?country.

Processing Techniques of Recycling Waste Carbide

It is reported that there are currently about 30 different processing techniques used for the recycling of waste cemented carbide. Below is a brief introduction to several of the most commonly used and effective techniques in production.

Nitrate Fusion Method

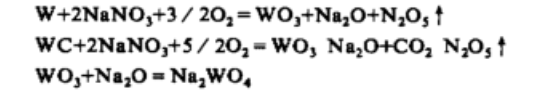

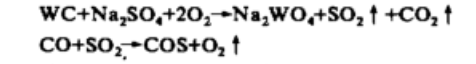

This method involves melting waste cemented carbide together with nitrate at temperatures ranging from 900°C to 1200°C, resulting in the formation of soluble sodium tungstate. The reaction equation is as follows:

At this stage, the cooled melt is crushed and then leached with water to obtain a sodium tungstate solution and cobalt residue, which are then processed through normal procedures.

The advantages and disadvantages of this method are as follows: it has a large processing capacity and a wide range of applications, but it suffers from low recovery rates, high costs, poor working conditions, and significant pollution.

High-Temperature Oxidation Method

This method involves placing the cemented carbide in a temperature range of 700–950°C to oxidize it in air or oxygen. During this process, oxygen reacts with the alloy through the following chemical reaction:

The oxidized product is a brittle substance that, when treated with sodium hydroxide or a mixture of sodium hydroxide and sodium carbonate in a high-pressure leaching device, yields a sodium tungstate solution. The cobalt remaining in the residue is separated out according to conventional processes.

Phosphoric acid leaching method

Immerse the waste carbide?in a phosphoric acid solution and leach at a temperature of 50-60°C. Phosphoric acid reacts with cobalt in the carbide?to form cobalt phosphate, which enters the solution and separates from tungsten carbide. The advantages and disadvantages are: since phosphoric acid is a weak acid, the problem of equipment corrosion is easily solved, making it suitable for processing various waste carbides. However, the recovered tungsten carbide has a high oxygen content, and the subsequent process flow is long.

Zinc melting method

React waste carbides with zinc at a temperature close to 900°C. The cobalt in the alloy forms a zinc-cobalt low-melting-point alloy, causing the tungsten carbide in the waste alloy to lose the cobalt’s bonding effect and become loose. Then, vacuum distillation is used to evaporate and recover the metal zinc.

After the zinc melting process, the waste carbide?consists of layers of tungsten carbide and cobalt layers arranged in a multi-layered and interlocking pattern. It is a loose bulk material, which, after crushing, becomes a recycled carbide?mixture.

The advantages and disadvantages of the zinc melting method are: the process and equipment are relatively simple, the actual recovery rate is high, the production process causes less pollution, and the recovered mixture can be used directly for the production of tungsten products. However, this method consumes a lot of energy, with an electricity consumption of 4000-10000 degrees for processing 1 ton of waste carbide, and the recovered material contains a small amount of zinc, which has a certain impact on product quality.

Sodium sulfate fusion method

This method involves reacting waste carbides with sodium sulfate at a temperature of 900-1000°C to form a molten tungstic acid. After cooling, it is then leached with hot water to obtain a sodium tungstate solution and cobalt slag. The reaction equation is as follows: (The specific reaction equation is not provided in the original text, so it cannot be translated here.)

Its advantages and disadvantages are: wide adaptability and large production capacity. The drawback is that sulfur dioxide gas is emitted during the production process.

Electrolysis fusion method of recycling waste carbide

This method involves placing the waste carbide?in an electrolytic cell as the anode, nickel plate as the cathode, and dilute hydrochloric acid as the electrolyte. After electrolysis, the cobalt in the carbide?enters the solution in the form of COCl?. The washed and ground WC can be directly used to produce alloys. This method yields pure products, is highly efficient, has simple equipment, and is easy to operate. It is particularly suitable for processing with high cobalt content and has high value for promotion and application.

Cold embrittlement method

The cold embrittlement method involves crushing the waste carbide?coarsely, removing impurities, and then using a high-speed air stream to inject the coarsely crushed carbide?into a vacuum chamber equipped with a carbide?paddle, followed by further crushing to obtain a mixture.

This method has a wide range of processing and treatment, and the production process does not cause environmental pollution, but the equipment cost is relatively high.

According to reports, the zinc dissolution method is widely used for the recycling of waste carbides in China at the current stage. Overseas, the most economical method is considered to be a combination of the zinc dissolution method and the cold embrittlement method. In summary, there are many methods for recycling and processing waste carbides, each with its own pros and cons. When selecting a method in practice, a comprehensive analysis and comparison should be conducted based on the type of waste carbide, the size of the production scale, equipment capacity, technical level, and the source of raw and auxiliary materials, to choose an advanced, reasonable, and economically significant process for production practice.

Technical and Economic Preliminary Evaluation of Several Process Methods for Recycling Waste Carbides

As mentioned earlier, the zinc fusion method, electrolysis dissolution method, and mechanical crushing method have all become the main industrial methods for recycling and regenerating waste carbides. The recycled and regenerated powders can be used to produce carbides through conventional processes, which undoubtedly promotes the full utilization of non-ferrous metal resources such as tungsten and cobalt, saves energy, reduces manufacturing costs, promotes the development of small and medium-sized enterprises, and provides employment for the unemployed. Among them, the powder produced by the electrolysis dissolution method is particularly good in quality with low impurity content, low energy consumption, moderate processing costs, and good economic benefits (the selling price of WC powder is only 60% to 70% of the conventional product). It is one of the main methods being vigorously developed in many regions of our country.

Summary

It should be pointed out that the recycling and regeneration of waste carbides is a new venture and an emerging industrial sector in the field of carbides, which should be affirmed and supported. At the same time, great attention must be paid to product quality in the work of recycling and utilizing waste carbides, especially since most enterprises are still at a relatively low level of manual workshop production. Many enterprises often focus only on economic benefits while neglecting the control and testing of the recycling process and powder quality, which is incorrect. In the future, enterprises engaged in this kind of production should continuously improve and enhance the recycling process and product quality, strengthen the recognition of the importance of “product quality is the life of the enterprise,” and must not be careless. Otherwise, it will be difficult to maintain a firm foothold in the fierce market competition for a long time, let alone continue to develop and grow.