The Difference Between Drilling and Milling

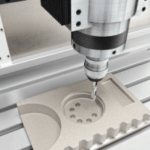

Drilling and milling are two different processes for machining a workpiece. A drill uses up and down motions to cut the material while milling uses sideways motions. The main difference between milling and drilling is the speed. Drilling requires a low spindle speed, while milling requires a high spindle speed.

Drilling is used for making holes in metal, while milling is used to create finished surfaces. Both methods can create the same hole, but drilling is more precise. Drilling also eliminates the possibility of cross-threading. Drilling is more effective for secondary work phases, while milling is best for primary work. While drilling can produce a clean workpiece, milling can result in waste material.

End mills have intermittent cutting edges that engage with the workpiece at high rotational speeds. Unlike drilling, end mills are not suitable for only plunging and can be used for peripheral or vertical plunging. End mills are used to cut thin walls and can also be used for vertical plunging. Both drills and mills have their advantages and disadvantages, but end mills are preferred for smaller plunging applications.

While the two processes share similar characteristics, there is a fundamental difference between them. Drill presses are less precise than milling machines. Milling machines have a table underneath the head that allows the piece to be positioned in the x and y directions. Drill presses have no table underneath the head, but you can build x and y guides to move the piece under the head.

Drill presses

Drill presses are tools that allow you to drill holes in materials, such as metal or wood. While milling machines are used for precision cutting, drill presses are more efficient for small jobs. A drill press uses a drill bit that is positioned on a fixed table and moves up and down in a single axis, while a milling machine operates in three axes simultaneously. A milling machine is more accurate than a drill press because it can apply a high rotational speed.

Drill presses do not require a high-tech tooling setup. Most of these machines have a circular column and a worktable that is clamped around it. The worktable cannot be stopped from rotating around this column, whereas a milling machine’s worktable can be rotated around a taper spindle. This will cause the workpiece to become misaligned, and can affect the accuracy of your job.

Milling machines are more expensive than drill presses. A milling machine is more versatile and can be used for complex shapes. A milling machine is designed for high speed and accuracy and requires much more space than a drill press. It’s also much heavier than a drill press and is usually not portable. It also takes up more floor space than a drill press, so be prepared for a large investment.

Drill presses are typically benchtop models. A benchtop drill press takes up little space, and is best for smaller jobs. Benchtop drill presses can drill 2″ to 3-3/8″ deep.

Milling machines

Milling machines are used in the manufacturing process to create complex shapes. They are also used in the tool room. The early milling machine was a horizontal one. It was a versatile machine used in the tool room, jobbing, and production processes. The advances of the 1860s made milling a widely used practice.

Milling machines use a spinning bit to drill holes in materials. While drills use up and down motions, milling machines use sideways motions to drill holes. The milling process also creates lateral loads on the spindle. Therefore, it is more expensive than drilling.

Various types of milling machines are available in the market. Some are horizontal while others are vertical. Their different specifications and orientations make them versatile in their application. They are usually used for small-scale manufacturing projects. They are also used in the construction industry. They are used for turning metal, wood, and other materials.

The primary difference between the two machines is the cutting edge. End mills are equipped with multiple cutting edges and are generally used to create conical surfaces. End mills can have up to 16 cutting edges. Both types of cutters can have many sharp edges. End mills are also more versatile, allowing them to produce high-quality surfaces.

A milling machine is a versatile and important tool in any shop. The price of milling machines varies greatly. The price range will depend on the swing & table size, the spindle to table max, the capacity, and the type of control.

Flexibility of end mills

There are several factors to consider when choosing an end mill. One of these factors is its flexibility. There are several types of end mills to choose from, including square and rounded ones. A square end mill, for example, is perfect for milling flat surfaces. A round end mill, on the other hand, has a more rounded tip and is better suited for high-detail contours. However, the downside to a round end mill is that it will require a lot of passes to achieve a flat surface.

Another type of end mill is a barrel endmill. These cutters are often referred to as barrels or ball-nose milling tools. They were initially used for drilling and milling complex dies, and for turbomachinery components. Today, however, their versatility has been greatly expanded thanks to developments in CAM systems and 5-axis machining.

A drill bit is the most common tool for drilling, but end mills are more versatile. They can be used for milling, drilling, or chamfering. However, a drill is more useful for smaller holes. When making holes that are less than 1.5mm, drills will be more effective, as end mills can be more brittle and cannot be run as aggressively.

The choice of material also plays a vital role in selecting the right end mill for the job. Different materials require different geometric tools and different machining strategies. A technician should first consider the processes necessary for the job. For example, a slotting operation will require a slotting solution, while conventional roughing will require a milling endmill with many flutes.

Speed of drilling vs milling

When drilling a hole, the speed of the drill machine will determine how deep it can go. This is a variable factor and may require a little trial and error. If the hole is large or very complex, you may need to slow down the drill speed or adjust the feed rate.

There are several advantages of milling over drilling. The first is that milling machines are usually more accurate. Modern milling machines are computer controlled. This helps the user input a specification quickly and accurately. Another benefit is that modern machines do not produce metal debris and do not overheat. A milling machine also does not require several passes over the same area.

End mills are more versatile than drills. They have multiple cutting edges and are capable of high rotational speeds. Drills are generally used for vertical plunging, while mills are used for horizontal and lateral cutting. End mills have cutting edges that engage the workpiece during every rotation.

The price of drilling and milling is comparable, but milling has lower material removal rates. While the cost of capital equipment is lower than drilling, operating costs (including depreciation) are higher. This is primarily because milling tools require more skilled operators and cost more than drilling equipment.

Quality of end product

Drilling and milling techniques require precision, lubricity, and control to ensure the best finish possible. The tools used are controlled by computers and use advanced technology. End products produced by these techniques are always more accurate and precise than those produced by manual tools. Modern milling machines also minimize friction during the cutting process, reducing the risk of overheating and other problems. And unlike traditional drilling devices, milling machines can handle different kinds of materials, including metal.

The drilling operation is performed using hand drills or drilling machines, while the milling process requires a milling machine. In drilling, the cutting edge contacts the workpiece continuously, while in milling, it engages and disengages the material during every tool rotation. This causes a difference in the length of the chips produced during the two processes.

Milling is best used as a secondary process to a machined workpiece. It helps define features of the end product by gradually removing material until the end product is the desired shape. Milling also provides a finishing coat on a workpiece that has already been machined.