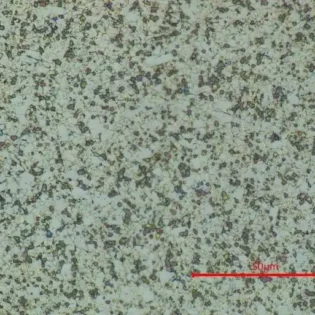

【introduction】Most of the metal, ceramic and semiconductor materials are made of polycrystalline. In contrast, although the performance of single crystal is often more excellent, but due to cost constraints, its scope of application is still very limited, can not achieve large-scale production. The traditional single crystal preparation technology includes the directional solidification method including the Bridgeman method and the Czochralski method. In addition, the single crystal can be synthesized by inducing the crystal growth abnormality. Polycrystalline material grain growth is usually large grain “phagocytic” small grain way to reduce the percentage of high energy grain boundary. If the grain grows in the normal way, the particle size distribution is relatively uniform; in some cases, only some of the grains “swallow” around the grain and grow rapidly, this situation is abnormal grain growth. Up to now, the application of single crystal materials, including shape memory alloy and heat-resistant alloys and other aspects, and shape memory alloy, copper – aluminum – manganese alloy in particular has a prominent cold workability. In addition, the superplasticity of this alloy increases significantly with increasing grain size. Therefore, if the traditional heat treatment can be used to achieve copper – aluminum – manganese alloy single – crystal large – scale preparation, then will undoubtedly greatly improve the application of the shape memory alloy prospects.In recent days, Professor Omori (Correspondent) research team at Northeastern University in Japan published an article entitled “Ultra-large single crystals by abnormal grain growth” at Nature Communications. The article pointed out that through the traditional heat treatment process, induced grain growth, and thus to achieve copper – aluminum – manganese alloy single – crystal large – volume preparation. Among them, the cyclic heat treatment provides the submicron boundary energy as the main driving force of the grain growth abnormality, while the further cyclic low temperature heat treatment improves the subgrain boundary energy, thus increasing the grain boundary migration rate. By such a heat treatment, the preparation of a 70 cm long single crystal bar can be achieved. The results of this research make it possible to monocrystalline other metals or ceramic materials with similar structures. In addition, due to the current single crystal material is one of the main applications of shape memory alloy, this large-scale preparation of single crystal method will greatly expand the existing shape memory alloy applications.Figure 1: Copper – aluminum – manganese single crystal bar and heat treatment processa. Circulation heat treatment process (high temperature cycle combined with low temperature cycle)b. Copper-aluminum-manganese monocrystalline rods prepared by cyclic heat treatmentc. Only high temperature heat treatment processd. copper-aluminum-manganese monocrystalline rods prepared by high temperature cycling heat treatment onlyFigure 2: Microstructure of copper-aluminum-manganese alloy prepared by abnormal grain growtha. Copper-aluminum-manganese alloy from 900 ℃ to 500 ℃ cycle end, after quenching the optical microscopeb. reverse pole projectionc. Reference orientation deviation of each grainFigure 3: abnormal growth phenomenon of graina. High temperature cycle heat treatment (900/500 ℃) process, the formation of sub-grain structure, part of the phase at 500 ℃ to form a precipitate. After the heat treatment, some of the grain in the sub-grain boundary driven by abnormal growthb. After several times of low temperature heat treatment (740/500 ℃), the grain boundary migration rate increases due to the increase of the orientation difference between the subgrains, so as to provide the possibility of large grainFigure 4: Grain boundary migration distance and subgrain structurea. After the alloy is heated at 800-500-800 ℃, it is incubated at 800 ℃ for a certain time (0min, 5min, 10min) and quenched to form microstructureb. alloy in the 740-500-740 ℃ temperature cycle five times, respectively, at 800 ℃ for a certain time (0min, 2min, 10min) and quenched by the formation of microstructurec. grain boundary migration distance of abnormal grainsd. grain reference orientation deviatione. Deviation from the orientation after one and five low temperature cyclesFigure 5: Superplasticity test of single crystal barSuperplasticity test of 15.4mm diameter and 682mm copper – aluminum – manganese single crystal bar【summary】In this paper, the preparation of copper-aluminum-manganese alloy with large single crystal is realized by rational design of alloy heat treatment process. First, through the five 900-500 ℃ high temperature cycle, the formation of bamboo-like structure in the alloy, and then through the four low temperature 740-500 ℃ cycle, access to grain boundary migration driving force, to achieve the abnormal growth of bamboo. This process has a long 700mm, diameter of 15mm single crystal bar has a good superplasticity. In addition, the experimental ideas for the realization of single-crystal mass production provides the possibility to broaden the application of shape memory alloy prospects. In addition to copper-aluminum-manganese alloy, copper-zinc, iron-chromium-cobalt-molybdenum and iron-manganese-aluminum-nickel alloys, which also have abnormal grain growth phenomena, are also expected to achieve high-volume production of single crystals.

Ngu?n: Meeyou cacbua