The basic edge shape (spiral groove shape) of end milling cutter can be divided into straight shape and spiral shape. The helix angle can be divided into 30 o, 45 o, 50 ° and so on. Compared with the straight edge, the spiral edge end milling cutter has the advantages of light cutting, smooth cutting, high efficiency and wide application range, so it has been widely used in milling. Now let’s talk about how to distinguish and use.

Features of end mill helix angle

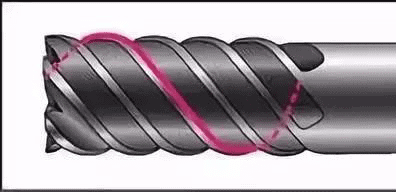

The larger the helix angle of the end mill, the longer the contact length between the workpiece and the cutting edge. This can reduce the load on the cutting edge per unit length, so it can prolong the tool life. However, at the same time, the cutting resistance will become larger, so the tool holder with high clamping rigidity must be considered.

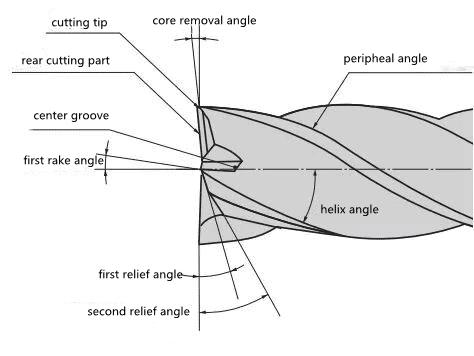

That’s what end mill’s cutting angles look like

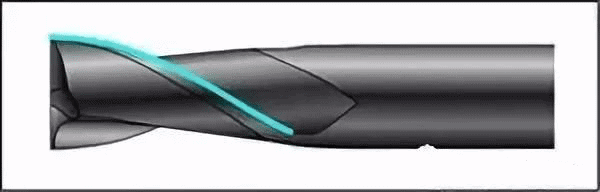

Small spiral angle end mill:

Cutting edge length (blue line part length) ? short

Large spiral angle end milling cutter:

Cutting edge length (length of red line) ?length

Types of helix angle

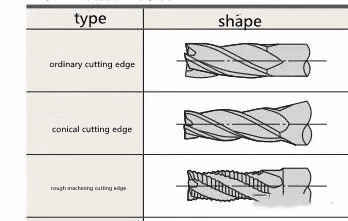

There are ordinary cutting edge, conical cutting edge and rough machining cutting edge

Relationship between helix angle and other machining parameters

1.Helix angle and cutting resistance

The tangential cutting resistance decreases with the increase of helix angle, and the axial cutting resistance increases with the increase of helix angle.

2.Helix angle and rake angle

With the increase of helix angle, the actual rake angle of end mill increases and the edge is sharper.

3.Helix angle and accuracy of machined surface

Generally, the perpendicularity and flatness tolerance of the machined surface increase with the increase of the helix angle, but when the helix angle is greater than 40 °, it decreases with the increase of the helix angle.

4.Helix angle and tool life

The wear speed of the circumferential edge belt is basically proportional to the helix angle; On the other hand, when the helix angle is very small, slight tool wear will also significantly reduce the cutting performance of the tool, cause vibration and make the tool unable to continue to use. When the helix angle is too large, the rigidity of the tool becomes worse and the service life decreases.

5.Helix angle and material to be cut

When processing soft materials with low hardness, use large spiral angle to increase the rake angle and improve the sharpness of the edge; When machining hard materials with high hardness, small helix angle is used to reduce the rake angle and improve the rigidity of the cutting edge.

Selection strategy of helix angle

For the difficult cutting materials of stainless steel with low thermal conductivity and great influence on the heat of the blade tip, the use of large spiral angle end milling cutter is helpful to prolong the tool life.

In addition, the characteristics of the finished surface change due to the helix angle. For example, when smooth finish machining is required, large helix angle end mills can sometimes be used. However, when using the end milling cutter with large spiral angle, the cutting resistance will increase and the force of the right spiral angle cutter will also increase. Therefore, corresponding measures must be taken, such as using a tool handle with high clamping rigidity. Although the rigidity of the cutter can be ensured, when the rigidity of workpieces such as thin plate processing is low, small spiral angle end mills are sometimes used.

Applicable occasions of various helix angles

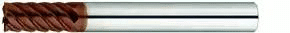

1.To choose large spiral end milling cutter with spiral angle of 50 °end mills for side finishing

multi edge design is adopted, with good tool rigidity, which can minimize the amount of tool yield during side cutting.

the sharp angle protection treatment of the blade tip can minimize the blade tip collapse.

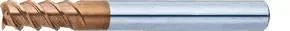

2.To choose 60 ° spiral angle end mill

suitable for high-speed cutting of SUS304 stainless steel and other difficult cutting materials

for difficult cutting materials with low thermal conductivity and easy rise of blade tip temperature during cutting, the unique blade shape can inhibit the influence of cutting heat on the blade tip.

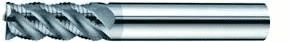

3.To choose high efficiency rough end milling cutter for high speed machining

45 ° helix angle and unique groove shape are adopted to realize high-speed machining and high wear resistance at the same time.

fine tooth chip breaking groove is adopted, and the surface roughness after processing is good.

the coating with excellent lubricity and good heat resistance (heat resistance temperature 1100 ℃) shall be adopted.

summary

Spiral angle is one of the main parameters of spiral edge end milling cutter. The change of spiral angle has a great impact on the cutting performance of the cutter. With the development of NC machining technology and flexible manufacturing technology, it is possible and very simple to change the spiral angle in the tool manufacturing process. If we further study the various effects of the spiral angle on the cutting performance of the spiral edge end milling cutter, when manufacturing and selecting the spiral edge end milling cutter, combined with the performance of the machine tool and tooling fixture, and comprehensively consider the performance of the processed material, machining accuracy, machining efficiency, tool material and tool life, optimizing the spiral angle will undoubtedly promote high efficiency High precision milling plays an important role.