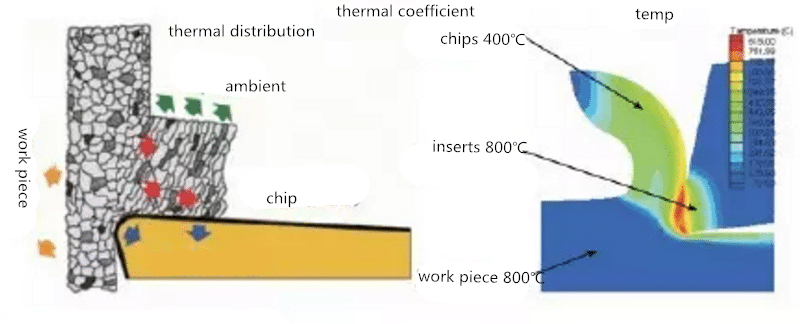

The temperature produced by metal cutting in the cutting zone is as high as 800-900 ℃. In the cutting zone, the cutting edge will make the workpiece material deform and cut it. In continuous turning, heat is produced in a stable linear way. On the contrary, the temperature of the cutting edge will increase and decrease alternately when the cutter teeth cut in and out the workpiece materials intermittently. The components of the machining system absorb the heat generated in the metal cutting process. Generally, 10% of the heat enters the workpiece, 80% enters the chip and 10% enters the tool. The best case is that the chips take most of the heat away, because high temperature will shorten the tool life and damage the processed parts.

Different thermal conductivity of workpiece materials and other processing factors will have a significant impact on the distribution of heat. When the workpiece with poor thermal conductivity is processed, the heat transferred into the tool will increase. Materials with higher hardness will produce more heat than those with lower hardness. In general, higher cutting speed will increase the generation of heat, and higher feed will increase the area affected by high temperature in the cutting edge.

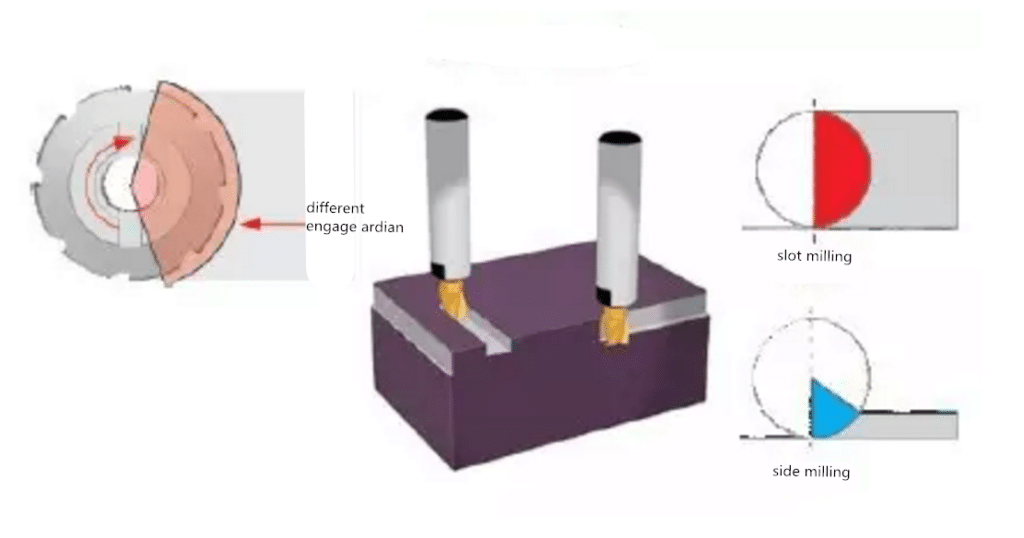

In the intermittent cutting condition, which is mainly milling, the selection of cutter’s engagement radian, feed rate, cutting speed and cutting edge groove shape has influence on the generation, absorption and control of heat.

Engagement radian

Due to the intermittent nature of milling process, cutting teeth only generate heat in part of the processing time. The cutting time percentage of the cutting teeth is determined by the engagement arc of the milling cutter, which is affected by the radial cutting depth and the cutter diameter.

The meshing arc of different milling processes is also different. In groove milling, the workpiece material surrounds half of the cutter, and the meshing arc is 100% of the cutter diameter. Half of the machining time of the cutting edge is spent on cutting, so the heat quickly accumulates. In side milling, a relatively small part of the tool is meshed with the workpiece, and the cutting edge has more opportunities to dissipate heat into the air.

cutting speed

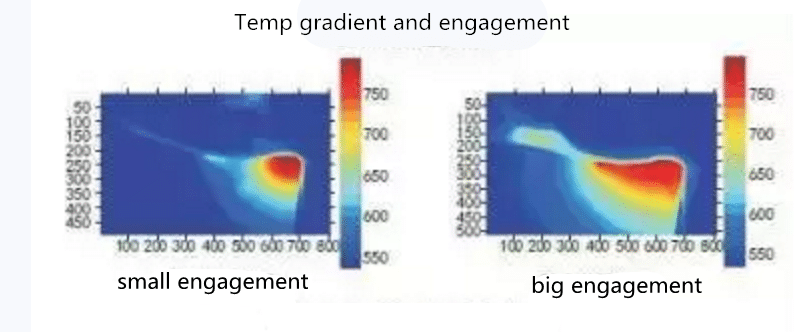

In order to maintain chip thickness and temperature in the cutting area equal to the value of the tool at full tool cutting, the tool supplier has developed a compensation factor to increase the cutting speed when the percentage of tool engagement decreases.

From the point of view of thermal load, the engagement arc is small, and the cutting time may not be enough to produce the minimum temperature required for the maximum tool life. Increasing the cutting speed usually produces more heat, and the combination of a small engagement arc and a higher cutting speed helps to raise the cutting temperature to the desired level. Higher cutting speed will shorten the contact time between cutting edge and chip, thus reducing the heat introduced into the tool. In general, higher cutting speeds reduce machining time and increase productivity.

On the other hand, lower cutting speed will reduce the machining temperature. Too much heat is produced in machining, reducing the cutting speed can reduce the temperature to an acceptable level.

?? dày c?t

Chip thickness has a great influence on heat and tool life. If the chip thickness is too large, the heavy load will produce too much heat and chips, and even lead to cutting edge fracture. If the chip thickness is too small, the cutting process is only carried out on a small part of the cutting edge, and the increased friction and heat will lead to rapid wear.

The thickness of chips produced in Milling will change with the cutting edge moving in and out of the workpiece. Therefore, the tool supplier uses the concept of “average chip thickness” to calculate the tool feed to maintain the most efficient chip thickness.

The factors involved in determining the correct feed rate include the engagement arc or radial cutting depth of the tool and the main deflection angle of the cutting edge. The larger the engagement arc is, the smaller the feed required to produce the ideal average chip thickness is. Similarly, the smaller the tool engagement arc is, the higher the feed rate is required to obtain the same chip thickness. The main deviation angle of the cutting edge of the tool will also affect the feed requirements. When the cutting edge deflection angle is 90 °, the chip thickness is the largest. Therefore, in order to achieve the same average chip thickness, reducing the cutting edge main deflection angle needs to increase the feed rate.

Cutting edge groove

The geometric angle of the milling cutter body and the cutting edge help to control the heat load. The hardness of workpiece material and its surface condition determine the selection of tool rake angle. The tool with positive rake angle produces less cutting force and heat, and can also use higher cutting speed. However, the positive rake tool is weaker than the negative rake tool, and the negative rake tool can produce more cutting force and higher cutting temperature.

The groove shape of cutting edge can cause and control cutting action and cutting force, thus affecting the generation of heat. The cutting edge of the tool in contact with the workpiece can be chamfered, passivated or sharp. The strength of the edge after chamfering or passivation is greater, resulting in greater cutting force and more heat. The sharp edge can reduce the cutting force and reduce the processing temperature.

The chamfering after cutting edge is used to guide chip, it can be positive chamfering or negative chamfering, positive chamfering will produce lower processing temperature at the same time, and negative chamfering design has higher strength and more heat.

The milling process is intermittent cutting, and the chip control characteristics of milling tools are usually not as important as in turning. It may be important to determine the energy required to form and guide the chip according to the workpiece material involved and the engagement arc. Narrow or forced chip breaking chip control groove can immediately roll up chips, and generate more cutting force and heat. The wider chip control groove can produce less cutting force and lower machining temperature, but it may not be suitable for some combination of workpiece materials and cutting parameters.

làm mát

The way to control the heat generated in metal cutting is to control the application of coolant. If the temperature is too high, the cutting edge will wear or deform quickly, so the heat must be controlled as soon as possible. In order to reduce the temperature effectively, the heat source must be cooled.

A variety of interrelated factors together form the load in metal cutting. In the process of processing, these factors will affect each other. In this paper, the heat problems in milling and their relationship with mechanical factors are discussed. Familiarity with the factors that produce metal cutting loads and the overall results of their interactions will help manufacturers optimize their machining processes and maximize productivity and profitability.