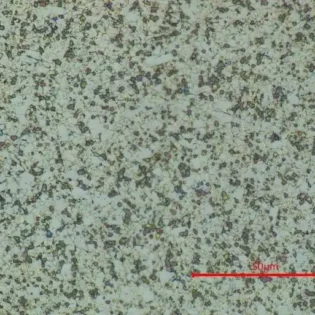

Principle of friction stir weldingFriction stir welding refers to the use of high-speed rotation of the welding tool and the workpiece friction heat to make the welding material local plastic, when the welding tool along the welding interface forward, the plasticized material in the welding tool friction From the front of the welding tool to the rear, and in the extrusion of the welding material to form a dense solid-phase weld.Common terms explained(1) Advancing Side (AS) and Retreating Side (RS): The weld is divided into two sides by means of friction and friction weld center. It is determined by the direction of rotation of the welding tool and the direction of advancement. On the front side of the weld, the direction of rotation of the welding tool is consistent with the direction of advancement of the welding tool. On the back side of the weld, the direction of rotation of the welding tool is opposite to that of the welding tool.Function: Some of the material flows forward on the forward side, and some of the material flows backwards and a larger mix occurs on the side. The material on the back side flows only backwards and some of the material enters the forward side. The plasticized metal in the upper part of the welding tool mainly flows downwards, and the plasticized metal in the front and lower part of the welding tool mainly flows along the welding side from the back side to the front side. The plasticized metal in the upper part of the welding tool has forward and upward The trend of flow, near the middle of the welding tool near the plasticized metal down, backward flow.(2) welding tool or welding head (Welding Tool): friction stir welding for the special tool called friction stir welding tool, referred to as welding or mixing head. Friction stir welding by the needle (Pin) and shoulder (Shoulder) composition, both known as the mixing needle and shoulder.Function: Shaft – Provides the thermal energy required for plasticizing the material in the weld zone by friction. The shape of the end of the shaft is concave to ensure that the softening material beneath it is subjected to inward force during the welding process and to accumulate, preventing the plasticized material from overflowing from the weld zone and forming the rear Of the cavity to fill, to ensure good weld forming. Mixing needle – in addition to friction through the provision of a part of the heat required, the main mechanical damage to the original base material to be welded, and the surrounding area by a strong stirring, resulting in docking the surface and the material near the full mixing, The formation of a large deformation characteristics of the fine equiaxed grains composed of welding nuclei.(3)Weld Nugget Zone, WNZ: The central part of the weld is called the core region, which has significant plastic deformation and complete dynamic recrystallization under the strong friction of the welding tool. Microstructure of Axial Grains.(4) Thermal-Mechanically Affected Zone (TMAZ): The peripheral area of the adjacent WNZ is TMAZ, which undergoes plastic deformation and partial recrystallization under the heat of the welding tool to form a microstructure composed of bent and elongated grains organization.(5) Heat Affected Zone (HAZ): Part of the area outside the TMAZ is HAZ, which is not subjected to mechanical agitation by the welding tool. Only the phenomenon of grain growth occurs under the action of frictional heat, forming a relatively coarse micro organization.Friction stir welding process shown in Figure 1, the microstructure of the distribution shown in Figure 2.Figure 1 Schematic diagram of friction stir weldingFigure 2 Composition of the microstructure area of the joint (BMZ is the base material)The advantages of friction stir welding: FSW weld through the plastic deformation and dynamic recrystallization, the microstructure of fine, fine grain, without melting the dendrites. Compared with the traditional welding method, there is no splash and smoke, no alloying elements burning, cracks and pores and other defects, do not need to add welding wire and protective gas; in the welding joint mechanical properties, than TIG and MIG welding has obvious advantages The connection of non-ferrous metal materials such as aluminum, magnesium, zinc, copper, etc., in terms of welding methods, joint mechanical properties and production efficiency. FSW have shown unparalleled superiority in other welding methods.Friction stir welding applicationRecently, the successful application of FSW materials are Al alloy, Mg alloy, lead, zinc, copper, stainless steel, low carbon steel and other similar materials or other materials, friction stir welding is mainly used in aerospace, aviation, shipbuilding, vehicle and nuclear energy and other fields.Aviation: Boeing for the first time to invest 15 million US dollars, from GMAW process to FSW process, welding defect rate reduced by 10 times, product performance increased by 30% or more. The use of friction stir welding aircraft has been taken off at Boeing.Ship: China Aviation Industry Beijing Foster Technology Co., Ltd. independent research and development success of China’s first ship with reinforced wall friction stir welding equipment, the device can be welded length 12m, width 6m, thickness of 12mm aluminum alloy with a wall, To meet the Chinese Navy new missile boats development needs.The automobile industry: the car door connection has been used friction stir welding technology connection, the effect is good, as shown in Figure 3.Figure 3 FSW connection of car doorsFriction stir welding development direction(1) friction stir welding composite technologyFigure 4 is the schematic diagram of reciprocating friction stir welding, the principle is the mixing head in the friction stir welding process of periodic rotation and reverse of the reciprocating motion; the same time, Figure 5 for the skew friction stir welding schematic diagram, the principle is the use of asymmetric mixing head to achieve friction stir welding. During the welding process, there is an inclination angle between the central axis of the stirring head and the rotating central axis of the welding machine, so as to achieve the skew-type agitation of the weld.Figure 4 reciprocating friction stir weldingFigure 5 skewed friction stir welding(2) stirring friction modification technologyIncluding surface direct modification and casting material modification. The principle of direct surface modification is to rub the surface of the workpiece with the stirrer which only has the shoulder without stirring the needle. The area through which the stirring head passes is to form a surface modified layer, which can be surface-modified purpose.References:[1] 姚君山, 張彥華, 王國慶, 等.?dāng)嚢枘Σ梁讣夹g(shù)研究進展[J].宇航材料工藝, 2003, (4):23-29.[2] 欒國紅, 郭德倫. 攪拌摩擦焊技術(shù)在中國的發(fā)展和推廣應(yīng)用[J]. 航空制造技術(shù)2014, (17):71-75.

Kaynak: Meeyou Carbide