You should learn about mining inserts and various mining bits tipped with them, whether you work for crude&gas industry, mining industry, or construction. I can see why it comes cause you realize works in these industries, more knowledge of tools you obtain, less hazardous condition and risk your guys will confront. As a manufacturer with exportation of mining tips gradually taking up one fourth of our whole annual throughput, we are thrilled to write this blog sharing some fundamental stuff about carbide mining tips that we are fabricating and familiar with. It couldn’t be better if it assists in knowing the categories of drilling tips made of carbide and what mining rigs they are used on.

*Kay?t i?in, Meetyou carbide Co., Ltd.'nin tüm i?eri?i, profesyonel mühendislik muhakemesinin yerine ge?mez, ki?isel deneyime ek ama?l?d?r.

Karbür madencili?i kesici u?lar?n?n Ana ?zellikleri

All mining tips are designed for ensuring?themself?as durable as possible regardless of the rock and dribs?involved.?whether made of pure WC-Co carbide or sintered polycrystalline diamond&carbide compact,?they are both characterized by their unique particle size and distribution of Co atoms offering themselves outstanding abrasion resistance, compact toughness, and the foremost stiffness against heat deformation.

Tane büyüklü?ü:?In contrast with?powders of carbide cutting tools, those of mining inserts are supposed to be as big as possible which normally?reach up to from 0.4μm to 3.5μm in diameter. Simply put,?that’s because?on the microscopic level?if a cracking occurs , it has to either pass through WC particles or get around them in a zigzag way. No matter which way the cracking goes, WC particles in bigger grain size cost it more fracture energy to penetrate, and meanwhile more surface area to skirt around. Consequently, the cracking propagation can be restrained. Statistic shows coarse carbide is 20% to 30% stronger than conventional carbide in toughness.

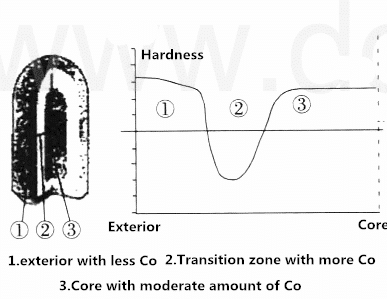

Co'nun Da??l?m?: ?te yandan, son y?llarda karbonlama i?lemi teknolojisi, bir karbür par?adaki Co'nun periferik b?lgeden merkez b?lgeye aktar?lmas? i?in ilerlemi?tir, bu da ?ekirdekte daha fazla Kobalt ve d??ar?da daha az Co olmas?n? sa?lar. Bir?ok deney, Co da??l?m? (iki fazl? semente karbür olarak adland?r?lan) dahil olmak üzere karbür par?alar?n, normal olarak tasarlanm?? karbür par?alara k?yasla d?? k?s?mda daha fazla giyilebilir ve i? k?s?mda darbeye dayan?kl? oldu?unu kan?tlam??t?r.

?nceki 2 noktaya ek olarak, madencilik u?lar?, u?tan uca birle?tirildi?inde ?e?itli a??r? yük ve cevher kütleleriyle ba?a ??kma performans?n? optimize etmek i?in farkl? ?ekillere uyarlanm??t?r.

Percussion mining bits:?DTH sondaj kulesi ve elektrikli k?r?c?,

Rotary mining bits: koni biti, koruyucu TBM s?y?r?c? (yeralt? tünel a?ma i?in) ve kesme ucu (püf noktas? makinesi ve k?mür kesici i?in)

madencilik endüstrisinde aksesuar??rne?in ta??ma band? s?y?r?c? b??a??(at?k ve at?k temizleme sistemi), vb.

Resimlerdeki tüm karbür u?lar? inceledikten birka? dakika sonra, umar?z bunlar hakk?nda sa?lam bir izlenim b?rakm??s?n?zd?r. Ard?ndan, bir sonraki metinden hangi alet u?lar?na tak?ld?klar?n? ve neler yapabildiklerini ??reneceksiniz. Resimde belirtilen s?ralamaya g?re a??klanacakt?r.

Percussion rock mining bit

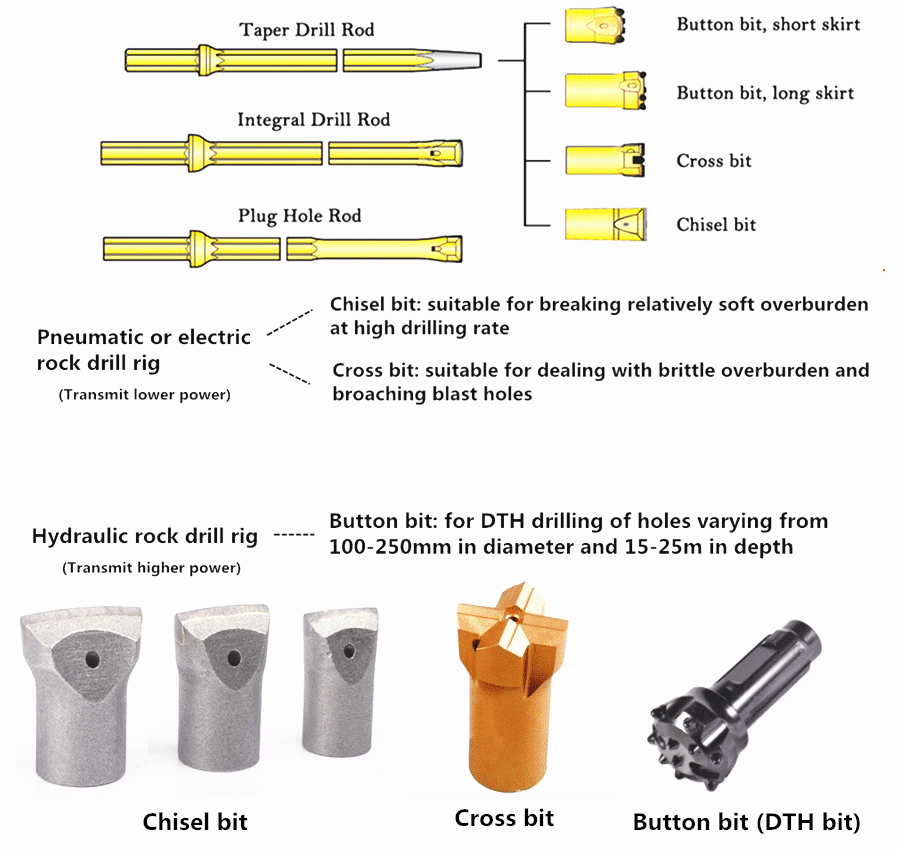

Exactly as its name implies, The function of percussion rock mining bits is largely dependent on the principle of percussion mechanism. Its built-in motor generates a percussive energy periodically thrust its bore head into ground creating many crackings and within each interval, the bore head rotates at a certain degree, which results in all overburden in the area that the rock mining bit covers gets smashed into small debris. Then a compressed air or a stream of high-pressure fluid comes out from a hole in bore stem and flush away all debris to form a round hole.

In general, percussion rock drills are utilized for two main purposes,?the first of which is to bore blast holes for filling with?explosives.?Secondly, It used for crashing some solid material for good, such as cement blocks.

There are 3 types of carbide drill heads on percussion rock mining bit available in our store, showed in the picture.

Rotary rock mining bit

Differing from percussion bits,?rotary rock drill burrow itself into earth’s face relying on its cutting edge, where rocks get by rotary toque and longitudinal thrust. There are cone drill, coal electric jackdrill, coal cutting pick, rock core drill, and TBM scraper blade falling into this category.

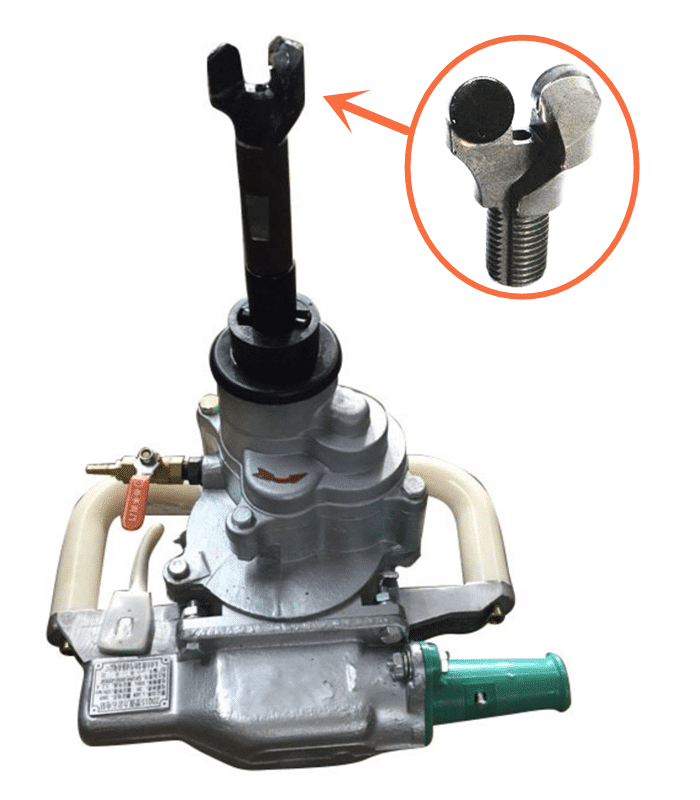

Elektrikli k?mür matkab? ?

Karbür veya PDC alt tabaka, ?ift kanat ucuna kaynaklanm??t?r. Bu tür portatif matkap, k?sa ?at? c?vatas? destek deli?i ve k?mür damar?n?n yüzünde patlatma deli?i delmek i?in kullan?l?r. Manuel ?al??t?rma s?ras?nda olu?an a??r? toz konsantrasyonunu ?nlemek i?in, genellikle 1 ila 2 m derinli?inde ve 45 mm'den kü?ük ?apl? delikler i?in ge?erlidir.

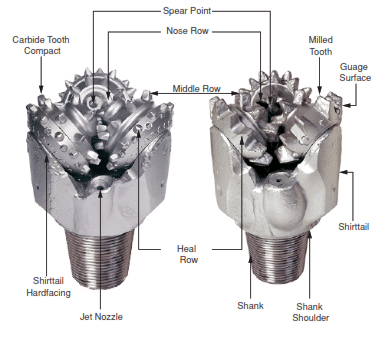

Cone mining bit

Makaral? koni ucu olarak da adland?r?l?r, ?ünkü sondaj dizisinde geleneksel olarak iki veya ü? ayr? ayr? d?nen konik alt u? vard?r; bu, orta sert kaya olu?umunda 280-440 mm ?ap?ndaki patlama deliklerini ve ?aptaki kuyu deliklerini a?arken verimlili?i büyük ?l?üde art?r?r. 300 mm'ye kadar.

Bu arada, bir koni ucu se?ilirken dikkate al?nan birincil fakt?r kaya sertli?idir. Daha sert olu?um, k?sa di?li koni u?lar?n? gerektirirken, daha yumu?ak olu?um bunun tersini gerektirir.

In most time, carbide tips with high toughness and hardness are adopted on cone bits. ?These tips are devised in different shapes (showed as below) in order to gain prominent cutting ability. A layer of wear-resisting hardfacing covers the whole bit body for high wear resistance and prolonged tool life.

PDC mining bit(Polycrystalline diamond compact)

Another appropriate rotary drilling bit is PCD(poly crystalline diamond) embedded mining bit. Unlike roller cone drills, PDC drills belong to a sort of fix-cutter drag bit since they don’t have rotating cones and have to operate as a solid unit. All cutting movement is achieved in form of scraping materials by artificial diamond compact in various patterns. The diamond is sinterred into to a carbide matrix to form a integrated substrate. Admittedly PDC mining bits are capable of drilling stratum in compact strength less than 18000PSI and rock abrasiveness less than 41°. which means they are quite suitable for dealing with soft to medium hard materials, such as halite, gypsum, marlstone, limestone.

There are two common types of existence of PDC mining bits,

1.PCD alt tabaka, do?al elmas ?l?er koruma ?ubuklar? ile karbür u? g?vdesine lehimlenmi?tir.

2.PCD alt tabaka, karbür koruma ?ubuklar?yla mekanik olarak oturtularak ?elik g?vdeye g?mülür.

Elbette üzerlerinde giyilebilir bir sert kaplama ile korunuyorlar. ?

Selecting principle

Bundan sonra, uygun kalitede karbür madencili?i u?lar? se?me ilkesi gelir. Son derece sert kayalar?n delinmesi ve k?r?lmas? ile ilgili olarak, a??r i? delme makinelerinde gü?lü sertlik gereklidir. Bu nedenle, yaln?zca yüksek kobalt i?eri?ine sahip karbür karbürler uygundur. Sert ve k?r?lgan kayalar veya gü?lü a??nd?r?c?l??a sahip malzemeler i?in, dü?ük kobalt i?erikli sinterlenmi? karbür kaliteleri se?ilmelidir.

Please Visit our?website and mining community?for more information on tools used for mining exploration, processing,lab analysis, and safety.