Karbürlü kesici tak?mlar kesme i?lemlerinde olduk?a yayg?n olarak kullan?l?r ve do?ru se?im...

Yüksek mukavemet ve sertli?iyle bilinen Nano-WC-Co karbürleri, ... i?in umut vadeden bir alan? temsil ediyor.

Son y?llarda, YG8 tungsten karbür (WC) malzemeler mükemmel ?zellikleri nedeniyle giderek daha fazla ilgi g?rmektedir.

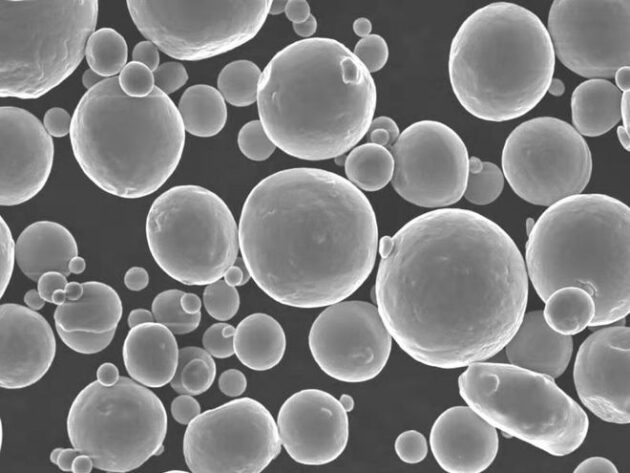

Coarse Tungsten Carbide (WC) is a fundamental raw material for producing coarse WC-Co alloys. The...

Cemented carbide is a significant type of cemented carbide, widely used in manufacturing cutting tools,...

The oxidation with temperature in the cutting area can reach 1000°C significantly reduces the hardness...

Research status For WC-Co carbide, the rapidly advancing Powder Bed Fusion (PBF) additive manufacturing (AM)...

Carbide?rods, due to their special properties of wear resistance, high hardness, excellent fracture toughness, and compressive strength, have been widely used in various fields such as metal processing, electronics industry, wood processing, aerospace industry, and medicine. They are ideal preliminary materials for manufacturing printed circuit board micro-drills, milling cutters, reamers, step tools, long rod tools, taps, and dot matrix printer needles. With the development of technology, the demand for carbide?rods is increasing, and forming techniques have evolved from traditional processes such as cold isostatic pressing and die pressing to more modern and economical extrusion molding processes, resulting in better quality and a wider variety of products.

Karbürün sinterlenmesi, karbür üretiminde ?ok ?nemli bir ad?md?r. Presleme i?lemi s?ras?nda...

?u anda alet imalat?nda uygulanan ba?l?ca iki tür 3D bask? teknolojisi vard?r. Bir...