Today’s heat treatment processes we share include: quenching, tempering, nitriding, cryogenic, oxidation and other processes. So what do these processes mean?

quench

s?ndürme nedir?

After austenitizing, the steel is cooled at an appropriate cooling rate to make martensite and other unstable structural transformation occur in the whole or a certain range of the cross section of the workpiece.

Purpose of quenching

1) Improve the mechanical properties of metal products or parts. For example: improve the hardness and wear resistance of tools and bearings, improve the elastic limit of springs, and improve the comprehensive mechanical properties of shaft parts.

2) Baz? ?zel ?eliklerin malzeme ?zelliklerini veya kimyasal ?zelliklerini iyile?tirin. Paslanmaz ?eli?in korozyon direncini geli?tirmek ve manyetik ?eli?in kal?c? manyetizmas?n? art?rmak gibi.

tempering

temperleme nedir?

The quenching workpiece is heated to an appropriate temperature below the critical point AC1 for a certain period of time, and then cooled by a satisfactory method to obtain the required microstructure and properties

What is the purpose of tempering?

1) To reduce the internal stress and brittleness, there is a great deal of stress and brittleness in the quenched parts. If it is not tempered in time, it will produce deformation and even cracking.

2) ?? par?as?n?n mekanik ?zelliklerini ayarlay?n. S?ndürme i?leminden sonra i? par?as? yüksek sertli?e ve k?r?lganl??a sahiptir. ?e?itli i? par?alar?n?n farkl? performans gereksinimlerini kar??lamak i?in sertlik, mukavemet, plastisite ve tokluk temperleme ile ayarlanabilir.

3) Stable workpiece size. By tempering, the metallographic structure tends to be stable, so as to ensure that no deformation will occur in the future.

4) The machinability of some alloy steels is improved.

nitridation

What is nitriding?

Nitriding treatment is a kind of chemical heat treatment process in which nitrogen atoms penetrate into the surface of workpiece in a certain medium at a certain temperature.

What is the purpose of nitriding?

The product has excellent wear resistance, fatigue resistance, corrosion resistance and high temperature resistance. Nitriding treatment is a kind of chemical heat treatment process in which nitrogen atoms penetrate into the surface of workpiece in a certain medium at a certain temperature.

Deep cold

What is deep cold?

Cryogenic treatment is to place the metal in – 160 ° The soft retained austenite is almost completely transformed into high strength martensite by treatment below C.

The purpose of deep cold?

Eliminate retained austenite (the retained austenite is about 8-20% after quenching and tempering, because the austenite is very unstable, it is easy to transform into martensite when it is subjected to external force or environmental temperature change, and the volume of martensite is larger than austenite, which will cause irregular expansion of the material and reduce the dimensional accuracy of the workpiece). After deep cooling, the retained austenite is reduced to less than 2%, which reduces the residual stress It makes the metal matrix more stable, increases the strength and toughness of the metal material, and significantly improves the red hardness.

oxidation

What is oxidation?

Dense and protective oxide film is formed on the surface of iron and steel parts by oxidation treatment. The main component is magnetic iron oxide (Fe3O4), which has the function of anti adhesion. The FES film obtained by surface vulcanization can have the function of anti-wear and anti adhesion. At the same time, it can improve the corrosion resistance and high temperature oxidation resistance.

What is the difference between different processes and workpieces?

Do you think the above technologies are not clear enough? So, the small Olympics will show you intuitively what are the differences in the appearance of different processes?

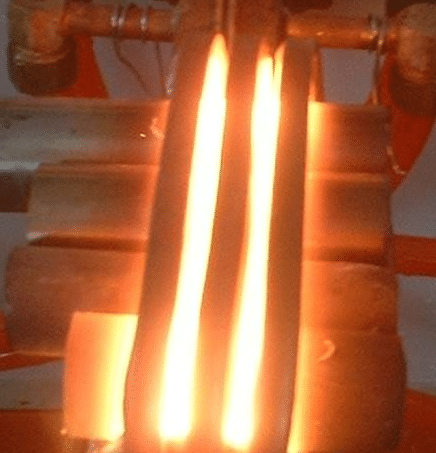

Quenching and tempering![What's Differences between the Main Five Hot Processing Methods 4 What's Differences between the Main Five Hot Processing Methods 4]()

The color is gray cyan

Deep cold

There is frost on the surface, so hands can’t touch it directly

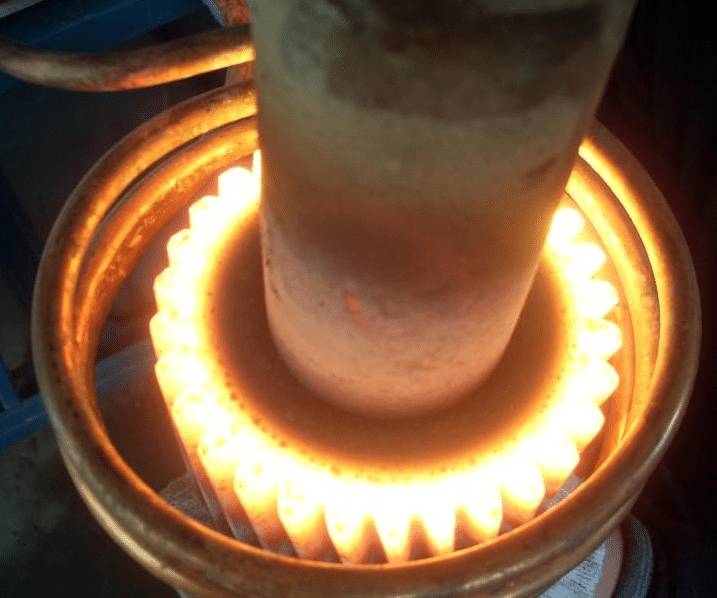

nitridation![What's Differences between the Main Five Hot Processing Methods 6 What's Differences between the Main Five Hot Processing Methods 6]()

The surface is white and gray

It can be seen intuitively from the picture that firstly, the color of the workpiece will change, and secondly, the process is inseparable. If a workpiece needs higher hardness, it can be achieved by heat treatment.

For example, a mold can only be made of 10000 samples, but now it can be made of 100000 or even 1000000 samples by heat treatment, which greatly improves the utilization rate.