Формы износа на клапанах

В зависимости от условий и механизмов трения износ может принимать различные формы, среди которых наиболее распространенными типами являются абразивный износ, адгезионный износ, усталостный износ, коррозионный износ и эрозионный износ.

Общие параметры, используемые для характеристики износостойкости материала, включают объем износа, скорость износа, глубину износа, износостойкость и относительную износостойкость. Основным требованием к абразивной стойкости является то, что поверхность объекта должна иметь высокую твердость (твердость поверхности должна превышать твердость абразива). Кроме того, она должна обладать хорошей стойкостью к окислению при рабочей температуре. Наиболее эффективным способом контроля или минимизации износа является повышение твердости и износостойкости материала.

Спеченный карбид вольфрама имеет высокую прочность, гладкую поверхность и более низкий коэффициент трения по сравнению со сталью при использовании в сочетании с другими материалами. Это значительно снижает силы трения контактной поверхности, эффективно снижая рабочий крутящий момент.

Свойства карбида

Цельный спеченный карбид получают путем высокотемпературного нагрева смеси вольфрама и углерода. Твердость большинства карбидов вольфрама очень высока, а микротвердость уступает только алмазу. Он имеет температуру плавления 2870°C и температуру кипения 6000°C, с относительной плотностью 15,63 (при 18°C). Он устойчив к разложению при высоких температурах и демонстрирует отличную стойкость к окислению.

Полевые исследования показывают, что карбид вольфрама демонстрирует износостойкость в таких ситуациях, как абразивный износ, эрозионный износ и истирание, которая примерно в 100 раз выше, чем у инструментальной стали, нержавеющей стали, железа и латуни. Он имеет в 2-3 раза большую жесткость, чем сталь, и в 4-6 раз большую жесткость, чем чугун и латунь, с ударопрочностью, аналогичной ударопрочности закаленной инструментальной стали.

Причина, по которой карбид необходим в клапанах

В условиях высокой температуры, высокого давления, сильной коррозии и пульп или порошков с твердыми частицами, таких как при газификации и поликристаллическом кремнии, уплотнительные поверхности обычных шаровых кранов с жестким уплотнением, регулирующих клапанов с V-образным отверстием, регулирующих клапанов для угольного порошка, дроссельных заслонок и золотниковых клапанов используют карбиды в качестве уплотнительных материалов для диска и седла клапана. Однако из-за ограничений напыляемого покрытия из карбида вольфрама — толщина <2 мм, твердость <60HRC и адгезия покрытия к подложке <1000 фунтов на квадратный дюйм — процесс напыления обычно проводится в жестких условиях при температурах до 10000 °C. Срок службы клапанов сложно гарантировать в течение 10 000 циклов, что затрудняет выполнение долгосрочных стабильных производственных требований систем, работающих с угольным химическим пульпой и поликристаллическим кремниевым порошком.

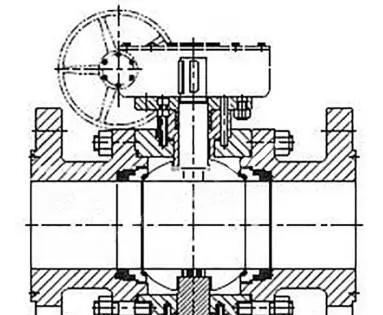

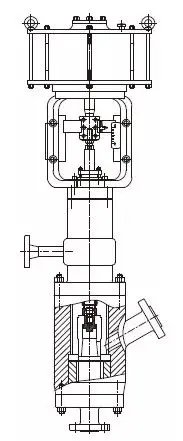

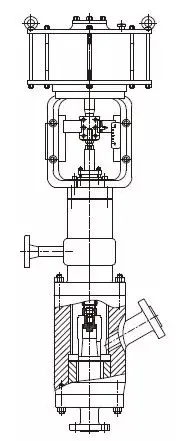

С другой стороны, прочность распыленного карбида вольфрама в основном зависит от основного материала, и когда коэффициенты теплового расширения двух материалов значительно различаются, использование ограничивается температурой и не может превышать 450 °C. Производительность клапана значительно улучшилась с принятием интегральных спеченных карбидов для тарелки и седла клапана в новых типах шаровых кранов с жестким уплотнением (рисунок 1), регулирующих клапанов с V-образным отверстием (рисунок 2), регулирующих клапанов для угольного порошка (рисунок 3), дроссельных клапанов (рисунок 4) и золотниковых клапанов, что решает эти проблемы.

инжир1 Уплотнительный шаровой кран

инжир2 регулирующий клапан

(1) Высокая твердость: твердость более 80HRC позволяет выдерживать высокоскоростную очистку многофазными твердыми частицами, такими как водно-угольная суспензия, угольный порошок и кремниевый порошок.

(2) Устойчивость к высоким температурам: способен длительно работать при температурах до 750°C, не имеет температурных ограничений по прочности, адгезии и тепловому расширению. Это полностью соответствует требованиям высокотемпературных условий, например, тех, которые встречаются в процессах химической переработки угля.

(3) Сопротивление высокому давлению: прочность на поперечный излом цельного спеченного карбида вольфрама достигает 4000 МПа, что более чем в 10 раз превышает прочность обычной стали. Он может работать в течение длительного времени при рабочих давлениях до 25 МПа.

(4) Коррозионная стойкость: Интегральный спеченный карбид вольфрама проявляет стабильные химические свойства. Он нерастворим в воде, не реагирует с соляной и серной кислотами и не растворяется даже в царской водке. Эта коррозионная стойкость удовлетворяет особым требованиям таких отраслей промышленности, как химическая переработка угля.

инжир3 Клапан управления угольным порошком

инжир4.?Дроссельный клапан

(5) Износостойкость: Высокая твердость и стабильность цельного спеченного карбида вольфрама обеспечивают превосходные противоизносные свойства для уплотнительных компонентов. Это соответствует особым требованиям к износу таких сред, как угольный порошок и органосиликон (твердость частиц кремниевого порошка составляет 62HRC).

(6) Устойчивость к эрозии: Обычные клапаны с напыленными покрытиями из карбида вольфрама на уплотнительных поверхностях часто страдают от сильной эрозии, проявляя сотовые узоры в течение месяца при условиях 250 °C и полностью теряя функциональность. Напротив, регулирующие клапаны с V-образным портом и регулирующие клапаны с угольным порошком, которые используют интегральный спеченный карбид вольфрама в качестве компонентов управления, имеют срок службы 12 месяцев при 450 °C (другие условия остаются прежними). Дисковые клапаны и золотниковые клапаны, подвергающиеся более чем 300 000 циклам переключения, полностью отвечают долгосрочным эксплуатационным требованиям таких отраслей, как химическая переработка угля в течение 8000 часов.

(7) Гибкость при высоких температурах: и шар, и седло изготовлены из цельных спеченных карбидов с коэффициентами термического расширения от 1/3 до 1/2 обычной стали. Это эффективно предотвращает распространенную проблему заедания клапана при высоких температурах, обеспечивая превосходные эксплуатационные характеристики в условиях перепада высоких температур.

(8) Низкое трение: использование противоизносных накладок из спеченного карбида не только продлевает срок службы накладок при высоких температурах, но и, благодаря их более низкому коэффициенту трения, обычно всего лишь 1/3-1/2 от обычных парных материалов. Это значительно снижает силы трения между компонентами, снижая рабочий крутящий момент клапана.

Вывод

Интегральный спеченный карбид обладает высокой прочностью, высокой твердостью, высокой температурой плавления, стабильностью, низким коэффициентом трения, износостойкостью, эрозионной и кавитационной стойкостью, коррозионной стойкостью. Изготовление износостойких уплотнительных элементов клапанов для сложных условий эксплуатации повысило применимость клапанов, расширило область их применения, продлило срок их службы, обеспечило различные эксплуатационные показатели и удовлетворило потребности развития химической промышленности.