Today we’ll talk about a interesting and basal concept “interpolation”. From a long time ago, engineers have been thinking about how to use machine tools to process workpieces into curves. Their primary idea is to divide the motion coordinates of the tool and the workpiece into some minimum unit quantities, i.e. the minimum displacement. The CNC system will move the coordinates by several minimum displacement quantities (i.e. control the tool motion trajectory) according to the requirements of the part program, so as to realize the relative motion of the tool and the workpiece and complete the processing of the part.

developed LATHE ALLOW INTERPOLATION

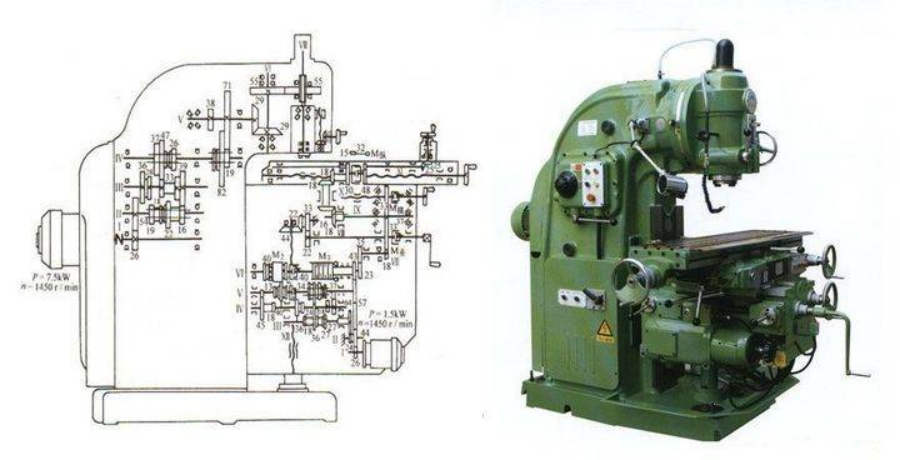

Before the information age, the motor used in the lathe could not change speed and move in the work, and there were many technical defects that were difficult to overcome in the face of precision machining. With the progress of technology, the machine tool has started to be updated.

Now, the automation technology has been further improved on CNC lathe, and the development of numerical control technology has entered the era of motion controller. In the open system of “PC + motion controller”, the machine tool processing has obtained stronger information processing ability, more accurate motion trajectory and better versatility.

However, although the technology has been improved, the processing needs to face more difficulties. In the process of workpiece processing, the machine tool often has to face irregular curve or arc processing. Although the machine tool can well complete the relative movement of linear segments, arcs or other analytical spline curves, in the face of irregular “free” movement, the machine tool has to rely on multi-axis motion control and interpolation.

concepts of Interpolation and pulse equivalent

Interpolation is the process of determining the motion path of the tool on the CNC machine tool according to a certain method. According to the given speed and trajectory, add some new intermediate points between the known points of the trajectory, and control the workpiece table and the tool to pass through these intermediate points, so that the whole movement can be completed. To put it mildly, it means that the tool uses broken lines to draw the curve to be processed one by one, which is equivalent to approximating the required curve and surface with several small segments and arcs.

The relative movement of the tool along each coordinate axis is in the unit of pulse equivalent (mm / pulse). When the tool path is a straight line or an arc, the numerical control device performs “densification of data points” between the starting point and the end point coordinate values of the line segment or arc, obtains the coordinate values of a series of intermediate points, and then outputs pulses to each coordinate according to the coordinate values of the intermediate points to ensure that the required straight line or arc contour is processed.

Classification of interpolation method

Interpolation methods include linear interpolation, arc interpolation, spline interpolation, etc. As the name implies, linear interpolation is completed by the tool in a linear motion between two points; Arc interpolation is to calculate the point groups approaching the actual arc according to the interpolation digital information between the end points, control the cutter to move along these points, and process the arc curve.

The outline of a part is often various, including straight line, arc, arbitrary curve, spline, etc The tool of CNC machine tool can not be moved by the actual contour of the curve, but is moved by several small straight lines approximately, and the direction of tool moving is generally X and Y directions. Interpolation methods include: linear interpolation, arc interpolation, parabolic interpolation, spline interpolation, etc.

Linear interpolation

Line interpolation is a commonly used interpolation method on the lathe. In this method, the interpolation between two points is approximated along the point group of the straight line, and the motion of the tool is controlled along the straight line. The so-called linear interpolation is the interpolation method that can only be used for the actual contour is a straight line (if it is not a straight line, the curve can also be approximated by a segment of a line in the way of approximation, so that each segment can be interpolated by a straight line) First, assume that the starting point of the actual contour is a short section along the X direction (one pulse equivalent), and if the end point is found below the actual contour, the next line segment is a short section along the Y direction.

If the end point of the line segment is still below the actual contour, continue to walk a short section along the Y direction until it is above the actual contour, and then walk a short section in the X direction, and repeat the cycle until the end point of the contour is reached In this way, the actual contour is spliced by segments of broken lines. Although it is a broken line, if each segment of the cutting line is very small (within the allowable range of accuracy), then this segment of broken lines and the actual contour can be roughly regarded as the same curve, which is straight line interpolation

Arc interpolation

Circular interpolation is an interpolation method. In this method, according to the interpolation digital information between the points at both ends, the point group approaching the actual arc is calculated, and the cutter is controlled to move along these points to process the arc curve.

Real time interpolation algorithm for complex curve

Traditional CNC only provides linear and arc interpolation, while non-linear and arc curves are interpolated by segmented fitting of linear and arc. This method will lead to a series of problems such as large amount of data, poor accuracy, uneven feed speed and complex programming when processing complex curves, which will inevitably have a great impact on the processing quality and processing cost. Many people begin to seek a direct interpolation method for complex freeform curves and surfaces.

In recent years, scholars at home and abroad have done a lot of in-depth research on this, which has also produced many new interpolation methods. Such as aakima spline curve interpolation, cubic spline curve interpolation, Bezier curve interpolation, Pythagorean hodggraph curve interpolation, B-spline curve interpolation, etc. Because of the many advantages of B-spline curve, especially its powerful function in representing and designing the shape of free-form curve and surface, the research on the direct interpolation algorithm of free-space curve and surface is mostly focused on it.