Experimental method to research recycle carbide

Experimental raw material

In our experiment, samples of the recycle?materials were randomly selected for experiment. The analysis results of the recycle?materials are shown in Figure 1.

As can be seen from the above chart, the composition of recycle carbide differs from that of any carbide of it, showing irregular and diverse characteristics. This is because the brands of recycle carbide are not the same, and it is difficult to strictly distinguish them from each other just from their appearance

Experimental method

According to the composition characteristics of the above raw materials, the recycle carbide are properly blended. The blending method is to use 90wt% recycle carbide and 10wt% added ingredients (Co, C, and inhibitor) to make the blended grade (hereinafter referred to as CP10). Through the process research of cemented carbide production, the conclusion is drawn based on production data.

Wet grinding process

The wet grinding time is 48 hours, and the ball-to-material ratio is 4:1.

Experimental conditions

Conventional cemented carbide production equipment is used in the whole production process. The forming agent is rubber solution with 10.5% concentration. the recycle carbide is pressed into 5.25 × 6.5x20mm bending bars and carbide blades, and sintered in a 50kg vacuum sintering furnace (sintering processes are selected at 1420℃, 1440℃, 1460℃, 1480℃, etc.).

Experimental result

The performance of CP10 at different temperatures is shown in Table 2 and Table 3. As can be seen from the results in Table 2 and Table 3, the performance of CPIO carbide?products is good, and the dirty conditions of the carbide?products are within the allowable range, indicating that the purity of the recycle material is high. In other words, the process control of recovery is effective. In addition, through the comparison of different sintering processes, it can be seen that under different process conditions, the performance of the product is different.

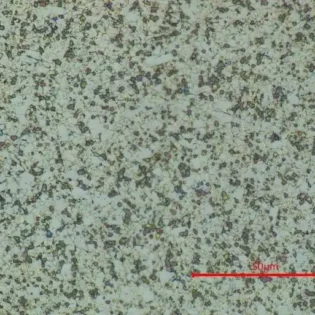

The metallographic photos of CP10 are shown in FIG. l to FIG. 4.?As can be seen from the following metallographic photos, the microstructure of CP10 is basically normal and the crystal size of the carbide?is relatively uniform. However, due to different sintering processes, there are some differences in the properties between the carbide produced at different temperatures.

Data analysis

It can be seen from the experimental results of CP10 that the properties of the carbide?are in good condition. As a whole, the hardness (HRA) of the carbide?is more than 91.5, and the strength of the higher carbide?is more than 1800(N/mm), which should be used in the manufacture of related blade products. As more than 90% of this brand carbide?is made of low cost waste carbide?recovery material, it has greater economic value.

In this experiment, we explored the influence of different sintering temperatures on the properties of CP10 carbide. It can be seen from the experimental results that the influence trend of sintering temperature on the properties of CP10 carbide?is roughly as follows: with the increase of sintering temperature, the porosity and the number of holes of the carbide?show a decreasing trend, the hardness decreases somewhat, and the strength and density of the carbide?improve in different degrees. This shows that the appropriate increase of sintering temperature of this kind of carbide?is helpful to improve the properties of the carbide. In this experiment, from the comprehensive consideration of process conditions and product quality, we believe that the sintering temperature of CP10 carbide?should be better at l460℃.

When the sintering temperature is 1420~C~1460~C, the coercive magnetic force of the carbides produced at different temperatures is almost the same. However, the samples sintered from 1420~C have the finer grain size and the highest hardness, which should have a higher coercive magnetic force, but the results are not the highest. In addition, the coercive magnetic force decreases greatly when the sintering temperature is increased to 1480~C. The reason of this phenomenon is mainly due to the uneven distribution of carbide?cobalt phase caused by different sintering temperature.

As can be seen from FIG. l and FIG. 4, there is an obvious uneven cobalt phase in the metallographic diagram of the carbide sintered at 1420℃ and 1480℃. When the carbide is sintered at low or underfiring temperatures, uneven distribution of cobalt layers and low coercive force (He) of the carbide occur. However, when the carbide is sintered at a higher (or overfired) temperature, the grain growth and the thickness of the cobalt layer are both uneven, simultaneously the coercive force (He) decreases . The coercive magnetic force and grain size control of the carbides produced from recycle carbide remain to be further studied. Unfortunately, In this experiment we did not do the cutting performance experiment of CP10 blade.

Conclusion of our recycle carbide test

(1) recycle carbide through the use of feasible waste carbide recovery method, and then appropriate allocation, can get good carbide product raw materials, and through the process control, can produce good comprehensive performance of cemented carbide products.

(2)Due to its composition characteristics, some properties of recycle carbide are different from raw materials. In the production of carbide, the process control should be treated differently.