You should learn about mining inserts and various mining bits tipped with them, whether you work for crude&gas industry, mining industry, or construction. I can see why it comes cause you realize works in these industries, more knowledge of tools you obtain, less hazardous condition and risk your guys will confront. As a manufacturer with exportation of mining tips gradually taking up one fourth of our whole annual throughput, we are thrilled to write this blog sharing some fundamental stuff about carbide mining tips that we are fabricating and familiar with. It couldn’t be better if it assists in knowing the categories of drilling tips made of carbide and what mining rigs they are used on.

*For the record, all content of Meetyou carbide Co., Ltd. is intended for a supplement of personal experience, not replacing for professional engineering judgment.

Main Features of carbide mining inserts

All mining tips are designed for ensuring?themself?as durable as possible regardless of the rock and dribs?involved.?whether made of pure WC-Co carbide or sintered polycrystalline diamond&carbide compact,?they are both characterized by their unique particle size and distribution of Co atoms offering themselves outstanding abrasion resistance, compact toughness, and the foremost stiffness against heat deformation.

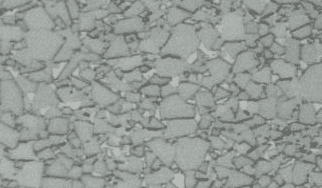

Grain size:?In contrast with?powders of carbide cutting tools, those of mining inserts are supposed to be as big as possible which normally?reach up to from 0.4μm to 3.5μm in diameter. Simply put,?that’s because?on the microscopic level?if a cracking occurs , it has to either pass through WC particles or get around them in a zigzag way. No matter which way the cracking goes, WC particles in bigger grain size cost it more fracture energy to penetrate, and meanwhile more surface area to skirt around. Consequently, the cracking propagation can be restrained. Statistic shows coarse carbide is 20% to 30% stronger than conventional carbide in toughness.

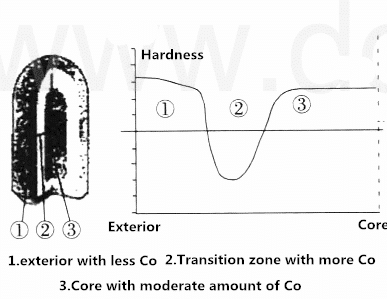

Distribution of Co: On the other hand, technology of carburizing treatment has been progressed in recent years for transferring Co from peripheral region to central area in a carbide part, which makes there is more Cobalt in core and less Co in outside. Many experiments have proven that carbide parts including that distribution of Co(so-called dual phase cemented carbide) are more wearable in exterior and percussion-resistant in interior, compared with normally designed carbide parts.

In addition to preceding 2 points, mining tips have be tailored into distinctive shapes for optimizing the performance in dealing with various overburden and ore bodies when they are assembled to bits blow.

Percussion mining bits:?DTH drilling rig and electric jackhammer,

Rotary mining bits: cone bit, shield TBM scraper (for underground tunneling), and cutting pick(for heading machine and coal cutter)

accessory in mining industry?such as convey belt scraper blade(waste and spoil cleaning system), etc.

Within few minutes of reviewing all carbide tips in the pictures, hopefully you have already made a solid impression of them. Then you will learn what tool bits they are mounted on and what on earth they are capable of from the next text. They will be expounded as their order that get indicated in the picture.

Percussion rock mining bit

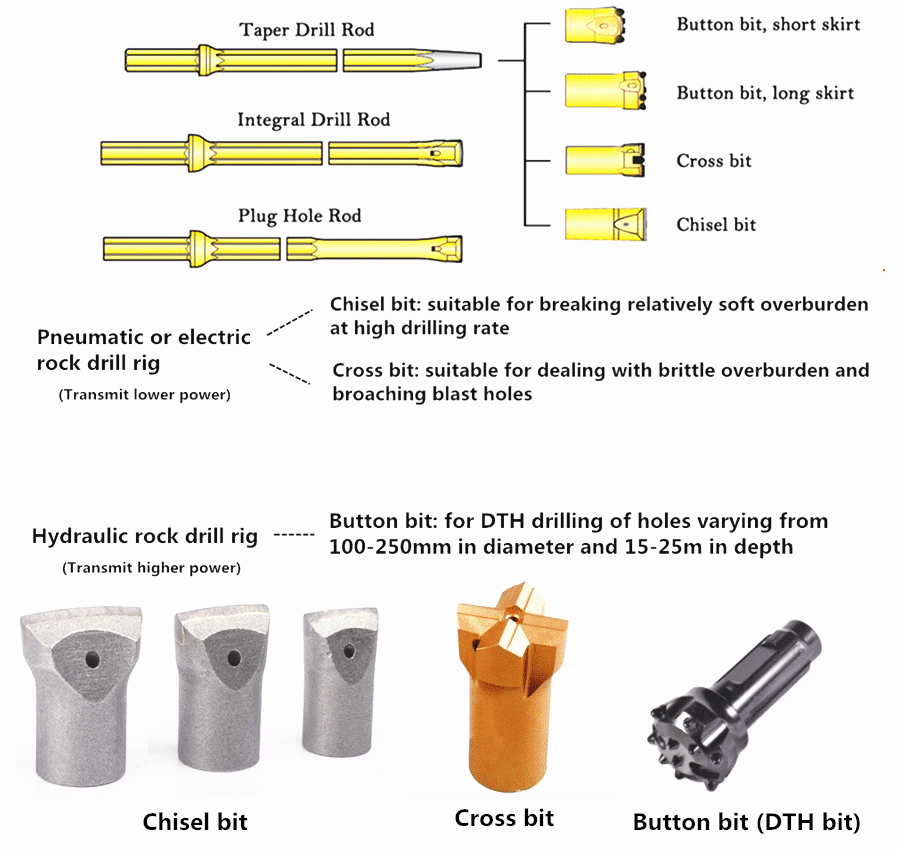

Exactly as its name implies, The function of percussion rock mining bits is largely dependent on the principle of percussion mechanism. Its built-in motor generates a percussive energy periodically thrust its bore head into ground creating many crackings and within each interval, the bore head rotates at a certain degree, which results in all overburden in the area that the rock mining bit covers gets smashed into small debris. Then a compressed air or a stream of high-pressure fluid comes out from a hole in bore stem and flush away all debris to form a round hole.

In general, percussion rock drills are utilized for two main purposes,?the first of which is to bore blast holes for filling with?explosives.?Secondly, It used for crashing some solid material for good, such as cement blocks.

There are 3 types of carbide drill heads on percussion rock mining bit available in our store, showed in the picture.

Rotary rock mining bit

Differing from percussion bits,?rotary rock drill burrow itself into earth’s face relying on its cutting edge, where rocks get by rotary toque and longitudinal thrust. There are cone drill, coal electric jackdrill, coal cutting pick, rock core drill, and TBM scraper blade falling into this category.

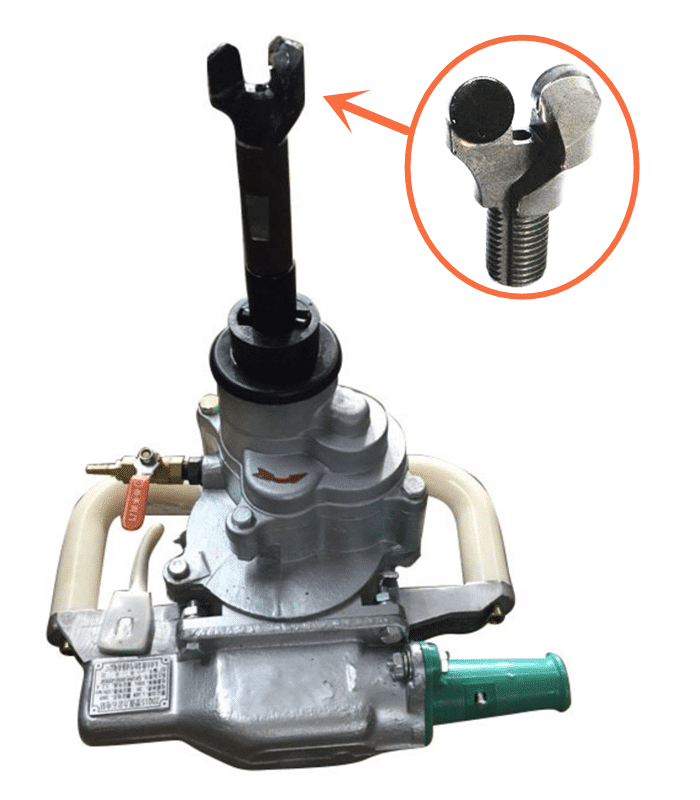

Electric coal jackdrill ?

With carbide or PDC substrate welded on its dual wing bit, This kind of portable drill is used for boring short roof-bolting support hole and blast hole on the face of coal seam. In order to avoiding excessive dust concentration occurred during manual operation, it’s usually applicable for holes in depth from 1 to 2m and diameter less than 45mm.

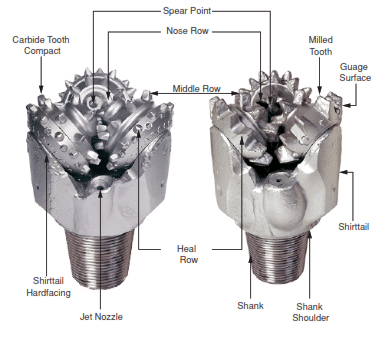

Cone mining bit

It’s also called roller cone bit cause there are conventionally two or three severally rotating conical sub-bits amounted on its drilling string, which greatly elevate the efficiency when drilling blast holes with 280-440mm in diameter on medium hard rock formation and wellbores in diameter up to 300mm.

By the way, rock hardness is the primary factor taken into account upon selecting a cone bit. Harder formation requires cone bits with short teeth, whereas softer formation requires the opposite.

In most time, carbide tips with high toughness and hardness are adopted on cone bits. ?These tips are devised in different shapes (showed as below) in order to gain prominent cutting ability. A layer of wear-resisting hardfacing covers the whole bit body for high wear resistance and prolonged tool life.

PDC mining bit(Polycrystalline diamond compact)

Another appropriate rotary drilling bit is PCD(poly crystalline diamond) embedded mining bit. Unlike roller cone drills, PDC drills belong to a sort of fix-cutter drag bit since they don’t have rotating cones and have to operate as a solid unit. All cutting movement is achieved in form of scraping materials by artificial diamond compact in various patterns. The diamond is sinterred into to a carbide matrix to form a integrated substrate. Admittedly PDC mining bits are capable of drilling stratum in compact strength less than 18000PSI and rock abrasiveness less than 41°. which means they are quite suitable for dealing with soft to medium hard materials, such as halite, gypsum, marlstone, limestone.

There are two common types of existence of PDC mining bits,

1.PCD substrate brazed into carbide bit body with nature diamond gauge protection bars.

2.PCD substrate embedded into steel body by mechanical fit with carbide protection bars.

Surely they are protected by a wearable hardfacing on them. ?

Selecting principle

Hereafter come the principle for selecting suitable grade of carbide mining inserts. Regarding drilling and breaking extremely hard rock, strong stiffness is required in heavy-duty drill machinery. Hence only the carbide carbide with high cobalt content are qualified. As to hard and brittle rocks or materials with strong corrosiveness, cemented carbide grades with low cobalt content should be chosen.

Please Visit our?website and mining community?for more information on tools used for mining exploration, processing,lab analysis, and safety.