Mining pick is one of the vulnerable parts in coal mining and roadway driving machinery, and it is the main tool for coal falling and coal breaking. Its performance directly affects the production capacity of coal mining machinery, power consumption, working stability and the service life of other related parts. With the increase of people’s demand for energy, especially for coal, in order to improve the mining efficiency, the power of the shearer is increasing, and the quality of the pick is required to be higher and higher. As the material of the shearer pick, it is required to have higher strength, hardness and wear resistance, bending strength and corrosion resistance.

Working process of shearer pick

Under the action of the front edge of the pick, the coal is broken and the large block is peeled off at the same time. At the moment when the tip contacts the coal, there are elastic and plastic deformation in the contact range of the tip. With the increase of the contact stress, when the strength limit is exceeded, the core is crushed into very fine powder to form a dense core, which is composed of the crushed coal under pressure. With the advance of the cutting tool, the dense core gradually grows and accumulates energy, and the cutting resistance also increases. The dense core compresses the front coal area and makes this part produce elastic deformation. Because the ore body around the dense core forms the stress state area, it actually plays a role in changing the geometry of the pick cutter head. When the contact stress of the cutter tip increases to the limit value, the dust in the area before the dense core ejects at a high speed, driving the small pieces to peel off.

Failure form

The main failure forms are the invalidation of alloy cutter head, chipping of cutter head, wear of alloy cutter head and gear body. In some working conditions, the failure of pick is often caused by the fracture of gear body. As the mechanical performance of the pick body directly affects the service life of the pick, it is of positive significance to select the material and effective heat treatment method of the pick body reasonably to reduce the wear and fracture of the pick, reduce the consumption of the pick of the shearer, improve the operation rate of the shearer and increase the comprehensive economic benefits of the production of the shearer.

Wear and fracture failure

In the process of cutting coal seam, the pick has strong friction and abrasive wear with the coal seam. The most stressed point of the pick is at the head of the working part of the pick, where the wear is the most serious, resulting in the wear and failure of the pick pants. In the actual coal production, about 50% of the pick failure is caused by wear.

Breaking and invalidation of cemented carbide tooth head

The invalidation of cemented carbide is related to the hardness of ore in coal and rock: when the pick cuts coal and rock, if the hard ore in coal and rock is encountered, the cutter head is in the state of high-pressure stress, and it will bear high shear stress at the place where the contact between the cutting edge and coal and rock is poor, and it is in the state of tensile stress. When the tensile stress exceeds the strength limit of the alloy, the cutter head will break.

For example, there are sand inclusions and microcracks in the weld, which cause the shear strength of the weld to be low. The abscission of cemented carbide is also related to the unreasonable size of weld gap. The use of less solder during brazing results in the loosening of cemented carbide head and the abscission of tooth head.

From the point of view of the material of the pick pant body, the reason for the invalidation of the carbide cutter head is related to the low hardness and poor wear resistance of the working part of the pick magazine body. The excessive wear of the part of the pick supporting the carbide results in the insufficient supporting force and the invalidation of the carbide. Therefore, by improving the hardness of the working part of the pick and the quality of brazing, the invalidation of cemented carbide can be avoided.

Performance improvement method

1. According to the hardness index of coal and rock, the corresponding grade of alloy cutter head is selected. Generally, the compressive strength of coal or coal rock roadway can be selected with less Co. the compressive strength of roadway surrounding rock should adopt the use of advanced technology such as limited or manufacturing composite alloy material spraying to improve the impact resistance.

2. The manufacturing process shall be in strict accordance with the design requirements, to ensure the matching between the pick and the gear holder, to ensure that the tool can rotate freely in the gear holder, to avoid the phenomenon of eccentric wear, the automatic grinding function, to maintain the normal wear of sharp blade and even cutting teeth, in the cut state. Brazing and heat treatment process. Brazing and heat treatment process is one of the key technologies for cutting quality of pick.

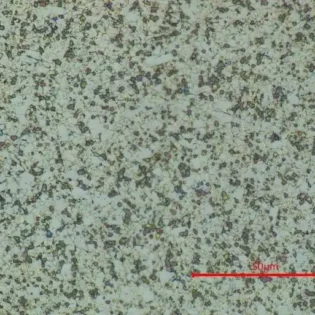

3. A layer of niobium carbide hard alloy is deposited on the surface of the coal pick steel machine by using the hardfacing technology to obtain the hardfacing wear-resistant layer with metallurgical structure with the base. Niobium carbide is distributed on the iron-based martensite and retained austenite intensively in the trading net of Chinese shearer, which protects the collective from wear. The Hardmetals with high hardness in the hardfacing layer and a large number of metallographic structures that play the role of wear-resistant framework make the hardfacing layer have high wear-resistance.

4. Thermal spraying can heat a linear or powdery material to a melting or semi melting state and accelerate the formation of high-speed droplet by means of heat sources such as flame, arc or plasma, spray to the substrate to form a coating on it, which can strengthen the surface of the material and improve its wear-resistant and corrosion-resistant properties.

5. Plasma cladding is a new material surface modification technology which uses plasma beam as heat source to obtain excellent wear resistance, corrosion resistance, heat resistance, impact resistance and other properties of metal surface. Plasma cladding is a rapid non-equilibrium solidification process, which has many strengthening effects such as supersaturated solution strengthening, dispersion strengthening and precipitation strengthening.

6. The brazing and heat treatment process of the pick is one of the key technologies to ensure the quality of the pick. At present, the brazing and heat treatment of pick are integrated technology. It is heated by vacuum furnace, so that the brazed pick can be directly quenched without air cooling, and the brazing and heat treatment can be completed once. It can avoid the oxidation phenomenon of the traditional brazing surface contacting with the air, ensure the direct contact between the melted solder and the brazing surface, and ensure the welding quality; at the same time, because the brazing and heat treatment are completed once, it can avoid the embrittlement of the alloy head and the reduction of the weld strength caused by the two heating.