Issues in Inner Bore Turning

1)Vibrating Cutting Tool

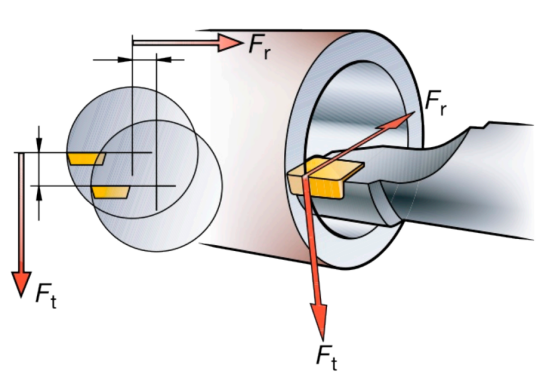

Excessive Overhang is the Primary Cause of Tool Deflection and Vibration Issues. In inner bore turning, the cutting tool experiences both radial and axial forces, causing the tool tip to deviate from its intended position. This deviation leads to tool holder deformation, with the extent of deformation becoming more pronounced as the tool holder’s length increases, consequently amplifying vibrations.

2)Poor Surface Quality

Poor Chip Evacuation may result in inferior surface quality of the workpiece. If chips cannot be effectively removed from the inner bore as planned, iron filings may become lodged and pressed against the inner walls of the workpiece, leading to the failure of the inner bore turning process.

Easy Breakage of Inner Bore Turning Tool Inserts

Vibrations and poor chip evacuation can lead to the fracture of inner bore turning tool inserts. During the processes of vibration and iron chip compression, the tool inserts of the inner bore turning tool are prone to edge chipping.

Solutions to Inner Bore Turning Issues

Basic principle

The general rule for inner bore machining is to minimize tool overhang and select the largest possible tool size to achieve the highest machining accuracy and stability.

Factors for Improving the Quality of Inner Bore Machining from the Tool Application Perspective

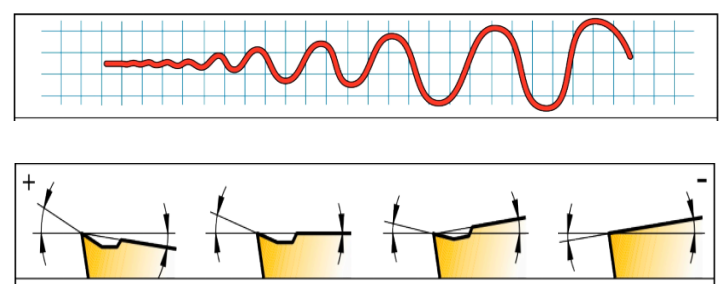

Selection of Inner Bore Turning Tool Insert Geometry: The choice of geometry for inner bore turning tool inserts has a decisive impact on the cutting process. For inner bore machining, tool inserts with a sharp cutting edge and high edge strength, such as positive rake angle inserts, are commonly preferred.

Selection of Tool Principal Clearance Angle: When choosing the principal clearance angle, it is recommended to select an angle as close to 90° as possible and not less than 75°. Otherwise, it may lead to a sharp increase in radial cutting forces.

Selection of Tool Tip Radius: In the process of inner bore turning, a smaller tool tip radius is preferred. Increasing the tool tip radius will result in larger radial and tangential cutting forces, as well as an increased risk of vibration tendencies. Meanwhile, ensuring the minimal radial cutting edge while using the maximum tool tip radius can yield a more robust cutting edge, improved surface texture, and a more uniform pressure distribution along the cutting edge.

Effective chip evacuation

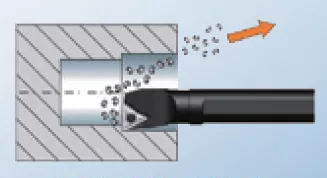

In inner bore turning operations, chip evacuation is crucial for both machining effectiveness and safety performance, particularly when dealing with deep holes and blind holes.

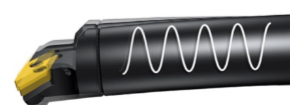

Short, helical chips are considered ideal for inner bore turning, as this type of chip is more easily evacuated and does not exert significant pressure on the cutting edge when breaking.

When the chips produced during machining are too short, the action of chip breaking becomes excessively strong, leading to higher machine power consumption and an increased tendency for vibrations.

On the other hand, excessively long chips can make chip evacuation more challenging. Centrifugal force pushes the long chips towards the hole wall, and the residual chips may be pressed onto the machined surface of the workpiece, posing a risk of chip blockage and potential damage to the cutting tool.

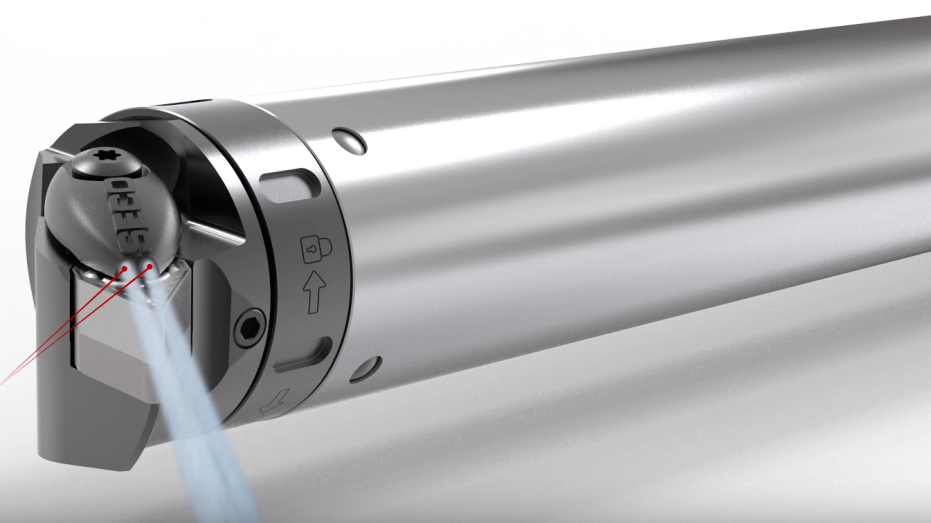

Therefore, when conducting inner bore turning, it is recommended to use tools equipped with internal cooling. This way, cutting fluid can effectively flush the chips out of the hole.

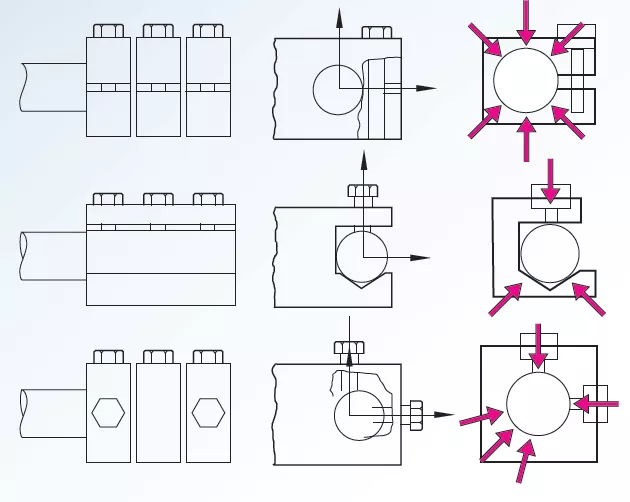

Selection of tool holding methods

The stability of tool clamping and the stability of the workpiece are also crucial in inner bore machining. They determine the magnitude of vibrations during machining and whether these vibrations will be amplified. The clamping unit of the tool holder meeting the recommended length, surface roughness, and hardness is of paramount importance.

Tool holders with overall support are preferable to those clamped directly with screws. Clamping the tool holder with screws on V-blocks is suitable, but clamping cylindrical shank tool holders directly with screws is not recommended, as direct screw action on the tool holder can cause damage.

Utilizing specialized tool holders

Damped Tool Holder: These types of tool holders typically use integral hard alloy bodies and are effective in reducing tool vibration, particularly in small hole applications.

Anti-vibration Tool Holder: This type of tool holder usually incorporates internal anti-vibration units, effectively reducing vibrations caused by excessive tool overhang. However, tools with such anti-vibration features tend to be expensive and are employed in demanding applications.