O processo de fresagem é essencialmente um tipo de processo de processamento intermitente. Isso faz com que a temperatura na aresta de corte flutue entre alta temperatura (cerca de 1000 ℃) e baixa temperatura.

Effect of cutting fluid

When the cutting edge cuts in and cuts out, the temperature change will increase. As a result, the cutting edge is subject to thermal shock and periodic stresses, which may result in cracks and, in the worst case, premature end of tool life.

The higher the temperature of the cutting area, the less suitable the cutting fluid is.

In the finishing process, the use of cutting fluid will not shorten the tool life as much as in rough machining due to the reduced heat generated.

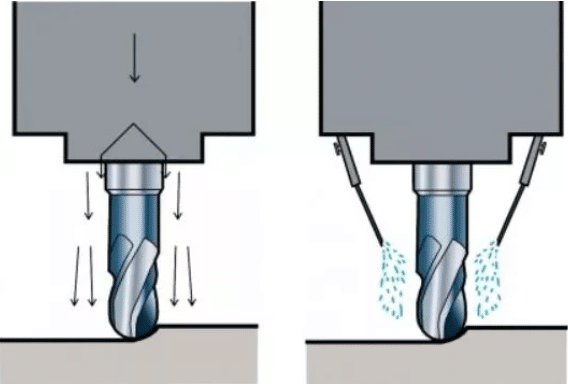

dry milling

Dry milling can prolong the life of cutting edge. The temperature does change, but it will remain within the design range of cemented carbide materials.

Rough milling should always be carried out without cutting fluid.

wet milling with cutting fluid

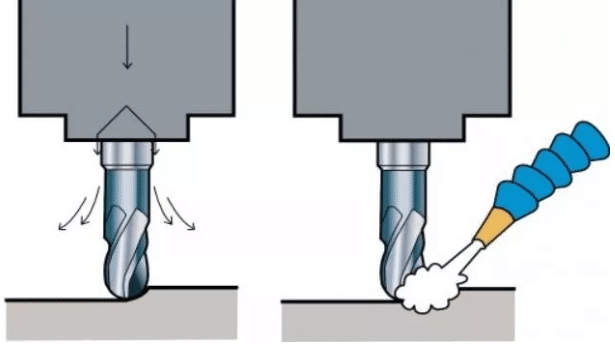

There are some exceptions to the use of cutting fluid:

1) Finish machining of stainless steel and aluminum alloys – used to prevent metal particles from sticking to the surface structure

2) Milling superalloys at low cutting speeds – for lubrication and cooling of parts

3) Cast iron milling, used to wet and remove dust to protect the environment and health and ensure the accuracy of parts

4) Milling of thin wall parts to prevent geometric deformation

5) When machining deep cavity, micro lubrication system (i.e. compressed air containing a small amount of special oil) can be used to assist chip removal

In the micro lubrication system, the “oil mist” is only a few milliliters of oil per hour, and is discharged through the ordinary filtering ventilation system.

If wet milling must be carried out, a sufficient amount of cutting fluid should be used.