Research status

For WC-Co carbide, the rapidly advancing Powder Bed Fusion (PBF) additive manufacturing (AM) technology has shown unique advantages in producing complex structures of metal parts made of carbide. However, when manufacturing WC-Co carbide with high melting points and high content of hard phases, issues such as difficult-to-eliminate cracks, pores, abnormal grain growth, oxidation decarburization, and brittleness often arise, leading to poor mechanical properties of the produced carbide. In recent years, there have been many reports on the use of Green Additive Manufacturing-Debinding and Sintering (GAM-DS) technology to fabricate WC-Co carbide, which have shown significant advantages in addressing issues such as cracking, abnormal grain growth, oxidation decarburization, and brittleness in PBF carbide. However, the process of preparing green bodies is prone to defects such as pores, interlayer cracks, uneven carbon distribution, and weak local bonding, resulting in problems such as porosity, uneven sintering shrinkage, and uneven microstructure in the sintered bodies. Compared with powder metallurgy, the prepared carbide have relatively low relative densities, and there is a significant gap in mechanical properties.

Brief introduction of research results

Recently, the State Key Laboratory of Powder Metallurgy at Central South University has employed Material Extrusion Additive Manufacturing (MEX) – Debinding and Sintering (DS) technology to successfully produce high-strength and tough WC-9Co cemented carbide with no pores, no cracks, and uniform shrinkage in all directions. Its relative density is approximately 99.7%, and its Vickers hardness, transverse fracture strength, and fracture toughness reach 1525±3HV30, 3492±45MPa, and 20.4±0.5 MPa·m1/2 respectively. The comprehensive mechanical properties are comparable to those of high-performance WC-Co carbide prepared by powder metallurgy processes. The relevant work, titled “Material extrusion additive manufacturing of WC-9Co cemented carbide,” was published in the top international journal “Additive Manufacturing.”

research chart

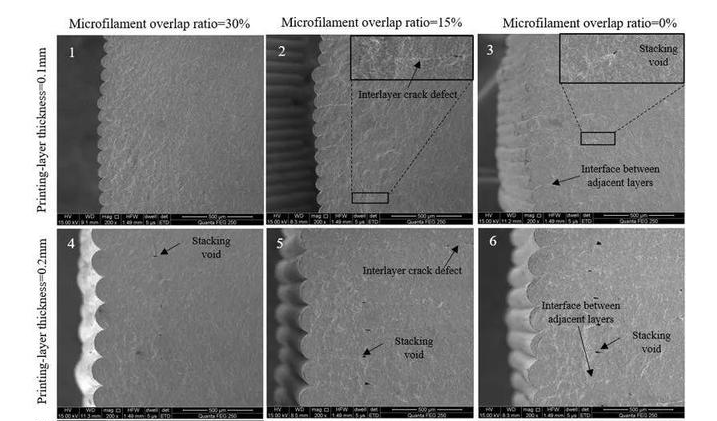

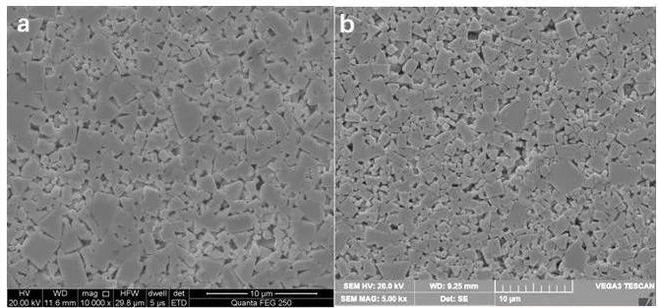

FIG. 1 Microstructure of MEX WC-9Co cemented carbide green

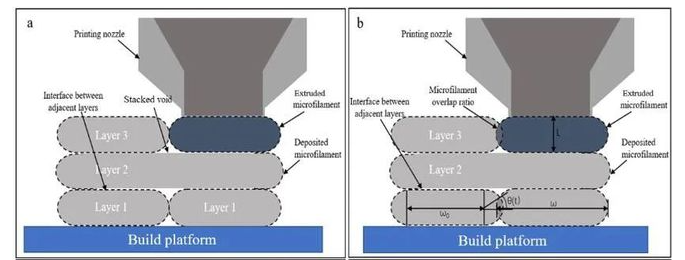

FIG. 2 Schematic diagram of stack pore formation of cemented carbide printing green billet: a. MEX stack pore formation; b. Increasing the overlap rate of microfilaments is conducive to reducing the stack porosity of green billet;

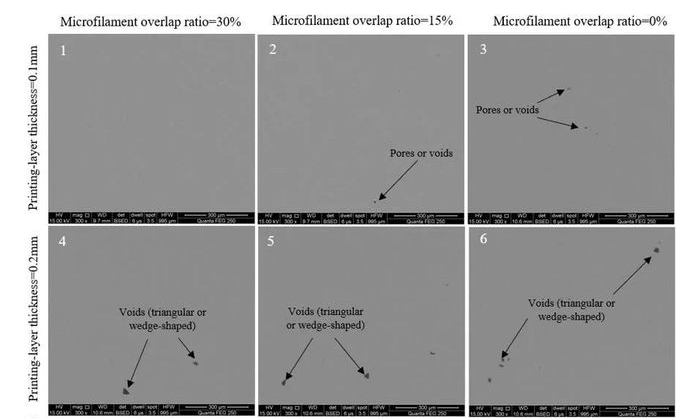

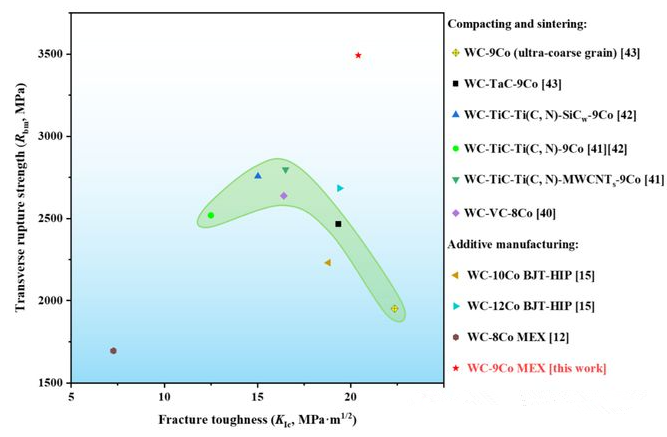

FIG. 3 Microstructure of MEX-DSWC-9Co cemented carbide

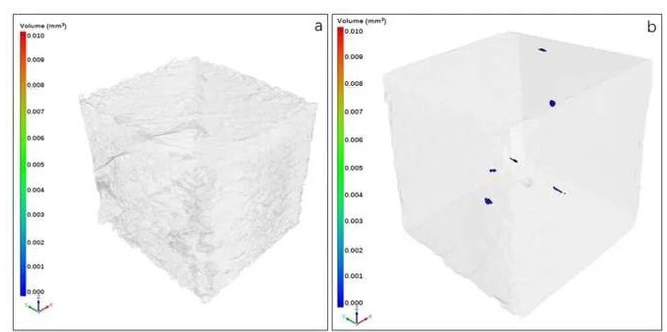

Figure 4 Micro-CT analysis results of internal defects in MEX-DS WC-9Co cemented carbide

Figure 5 Microstructure of WC-9Co cemented carbide: (a) MEX-DS; (b) Press forming – degreasing sintering

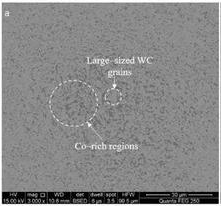

Figure 6 MEX-DS WC-Co carbide Co pool and Co rich zone

Figure 7 Transverse fracture strength and fracture toughness of WC-(8-12)Co cemented carbide prepared by different processes

Sumário

Conclusion of the Paper

(1) By calculating the plasticity index of the printed feedstock with a powder loading of 54 Vol.%, the mechanism of green body printing defects was analyzed, and the green body MEX parameters were optimized. Using optimized parameters such as a printing temperature of 150°C, filament overlap rate of 30%, and printing layer thickness of 0.1mm, defect-free green bodies of WC-9Co cemented carbide with a relative density of 98.5% were prepared.

(2) Both excessively high or low temperatures during the debinding process using n-heptane can lead to debinding cracks. Rapid solvent evaporation during the drying process of debound bodies can also result in microcracks. By employing a two-step solvent debinding process, namely, n-heptane debinding at 30°C for 12 hours followed by kerosene debinding at 30°C for 1 hour, the solvent evaporation rate was reduced, resulting in high-quality debound bodies with no noticeable debinding defects and uniform distribution of binder.

(3) Defects in MEX green bodies can lead to the formation of Co-rich regions or pools, abnormal WC grains, residual pores, etc., in WC-Co carbide. These defects can be improved or eliminated during the sintering process through liquid phase flow and rearrangement of WC particles. By optimizing the MEX green body printing and solvent debinding processes to eliminate printing and debinding defects, it is possible to eliminate defects such as sintering pores, cracks, Co pools, abnormal grain growth, etc., in WC-Co carbide, resulting in near-full-density WC-9Co carbide.

(4) By employing MEX green bodies, a two-step solvent debinding process, and a continuous thermal debinding-vacuum pressure sintering process, WC-9Co carbide with uniform microstructure, smaller grain size, and relatively uniform distribution were prepared. The Vickers hardness, transverse fracture strength, and fracture toughness were measured to be 1525±3HV30, 3492±45MPa, and 20.4±0.5MPa·m1/2, respectively. The comprehensive mechanical properties were superior to those reported by recent additive manufacturing technologies and comparable to those of WC-Co carbide prepared by traditional powder metallurgy processes.

Main Innovations of the paper of WC-Co carbide additive manufacturing

The use of WC-Co carbide MEX-DS technology to prepare near-full-density WC-9Co carbide, with a transverse fracture strength reaching 3492MPa and a fracture toughness exceeding 20MPa·m1/2, has significantly improved the transverse fracture strength of WC-Co carbide prepared by current AM methods (ranging from 1500-2000 MPa to 3000-4000MPa with HIP treatment) and increased fracture toughness to above 20MPa·m1/2. The comprehensive mechanical properties are significantly better than those reported by similar studies and comparable to similar products prepared by powder metallurgy. The research results are of great significance for addressing the challenging issues of porosity, cracks, and harmful phases encountered in current carbide additive manufacturing and for the development of carbide additive manufacturing technology.

Deixe uma resposta

O seu endere?o de e-mail n?o será publicado.