Orthogonal Experiment and Wear Resistance Test of cryogenic ?Treatment

experiment

An orthogonal experiment was conducted using a batch of YT15 carbide?rhombic indexable turning carbide inserts produced by our company. The orthogonal experiment consisted of 4 factors with 3 levels each. Subsequently, a CJK6132 lathe was used to cut 45 steel under identical cutting conditions. The wear resistance performance of the carbide inserts, both with and without cryogenic treatment, was compared, and the key factors influencing the effectiveness of cryogenic treatment were identified.

cutting parameters

The cutting depth (ap) is 0.3mm, the feed rate (f) is 0.25mm/r, and the spindle speed (n) of the machine tool is 450 rpm.

Experimental results and mechanism of enhancing the wear resistance of carbides by cryogenic treatment

Key factors affecting the effectiveness of cryogenic treatment

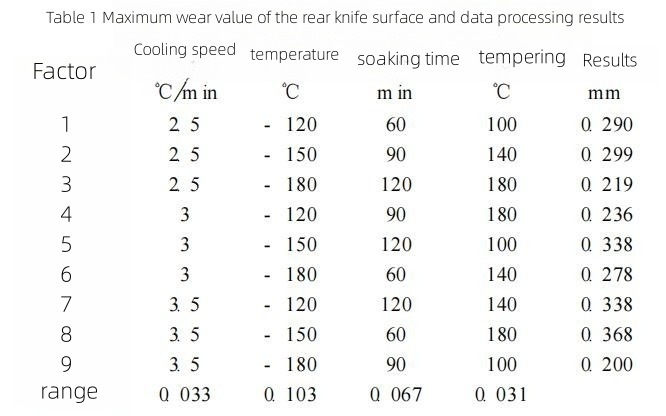

In this experiment, the maximum wear value on the rake face (Va) is taken as the wear indicator, and its wear curve is shown in Figure 1. The values of maximum wear value (Va) and the specific data processing results are shown in Table 1. The curves \9 in Figure 1 correspond to the rake faces treated with processes 1 to 9 in Table 1, while curve 10 corresponds to the untreated rake face. From the wear curve, it can be observed that the wear resistance of the carbide?tool significantly improves after cryogenic treatment compared to the untreated tool.

From Table 1, it can be seen that the range of Va caused by different cryogenic temperatures is 0.103mm, the range of Va caused by different insulation times is 0.067mm, the range of Va caused by different cooling rates is 0.033mm, and the range of Va caused by different tempering temperatures is 0.031mm. Therefore, it can be concluded that the key factor influencing the effectiveness of cryogenic treatment is the cryogenic temperature, followed by the insulation time, cooling rate, and tempering temperature.

YT 15??Hardness analysis of blade

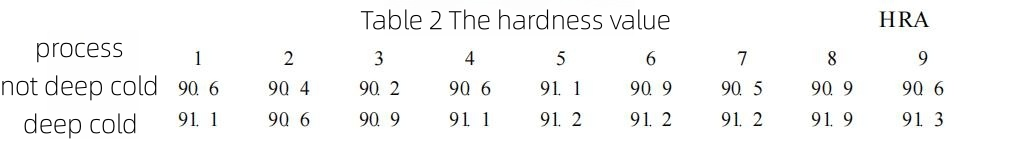

The wear resistance of carbide inserts is closely related to their hardness values. To investigate this, the Rockwell hardness (HRA) of the carbide inserts, both with and without cryogenic treatment, was measured, and the results are shown in Table 2.

From Table 2, it can be observed that the hardness value of the carbide inserts after cryogenic treatment is moderately higher compared to the untreated carbide inserts. This indicates that there is a certain difference in the microstructure between the two types of carbide inserts.

A vector along the lattice edge direction with a length equal to the lattice parameter is called a lattice basis vector, denoted as a, b, c respectively, and the length of the basis vector is known as the lattice constant. X-ray analysis results indicate that there is no significant difference in the lattice constants of WC in the carbide inserts after cryogenic treatment compared to the untreated ones. However, in the cryogenically treated YT15 carbide inserts, a larger amount of hexagonal close-packed Co (e Co) and a smaller amount of face-centered cubic Co (ar Co) were found. In contrast, the untreated YT15 carbide inserts exhibited a smaller amount of e Co and a larger amount of a+ Co. This indicates that cryogenic treatment leads to a certain amount of martensitic transformation of metallic Co in YT15, as revealed by X-ray analysis, with approximately 10% (by mass fraction) of α-Co converting into G Co.

Hexagonal close-packed metals exhibit lower friction coefficients. A lower friction coefficient is beneficial in reducing frictional forces during the cutting process, thereby lowering the cutting temperature, minimizing tool wear during cutting, and improving the wear resistance of the tool. Additionally, hexagonal close-packed metals have lower adhesive wear characteristics compared to body-centered and face-centered metals. Therefore, the transformation of α-Co to G Co after cryogenic treatment will reduce adhesive wear during the cutting process.

Therefore, the key reason why cryogenic treatment enhances the wear resistance of carbide inserts lies in its promotion of the martensitic transformation of α-Co to c Co.

YT15 Microstructure Analysis of Blade

The main components of YT15 carbide inserts are WC, binder phase Co, and TC, with mass fractions of 79%, 6%, and 15% respectively. The primary performance of these carbide inserts depends on the characteristics of WC and the binder phase Co.

The lattice constants of WC and TC in YT15 carbide inserts, after different treatment processes, were measured using an X-ray diffractometer (Model D8).

experiment result

(1) Cryogenic treatment significantly improves the wear resistance of YT15 carbide inserts. (2) The most crucial factor influencing the cryogenic treatment process is the cryogenic temperature, followed by the insulation time, cooling rate, and tempering temperature. (3) After cryogenic treatment, the Rockwell hardness of YT15 carbide inserts noticeably increases. X-ray diffraction analysis reveals that a certain amount of transformation occurs in the binder phase, from α-Co to ε-Co, in YT15 after cryogenic treatment. This transformation is a polymorphic martensitic transformation and is the main reason for the improved wear resistance of YT15 carbide inserts.