The ultra-fine tungsten steel cutting blades manufactured by Metayou carbide?Co., Ltd. have high smoothness, sharp cutting edges, and high wear resistance. They have a much longer lifespan compared to general tungsten steel blades, ranging from 20 to 150 times longer. They can cut hard materials with a hardness of around 50HRC. The one-time installation lifespan is 1.5 to 2 times longer than that of ordinary tungsten steel cutting blades, which significantly reduces the frequency of blade replacement and grinding, thus improving production efficiency. In particular, the dual-crystal tungsten steel cutting blades have excellent toughness, with almost no chipping or curling.

The material of these blades is generally YG8, with a density of 14.58g/m3, a hardness of 89.0HRA, and a bending strength of 2710N/mm2. Their advantages lie in their wide applicability, but they may have slightly lower sharpness and durability.

With the rapid development of China’s electronics industry in various fields such as charging power supplies, household appliances, mechanical equipment circuits, and LED lights, and the increasing demand for high-quality electronic products by consumers, whether for the safety of PCB circuits, better convenience for repairs, or to avoid short circuits or injuries caused by sharp PCB pins to operators’ fingers, it is increasingly necessary to ensure neat and burr-free cutting of PCB pins. As Chinese people’s environmental awareness strengthens and their pursuit of high work efficiency increases, all indications suggest that tungsten steel cutting blades will continue to evolve towards a more environmentally friendly, durable, and sharp direction.

Production detail of lead cutting machine: Blunting the blade edge

Although tungsten steel cutting blades for lead cutting machines have sharp edges, high hardness, and high wear resistance, they operate at high speeds during cutting. It is widely known that the higher the operating speed, the higher the heat generation and wear, and it also leads to thermal fatigue of the metal, resulting in reduced hardness. With reduced hardness, the wear resistance and sharpness of the blades naturally decrease, directly affecting their cutting performance. Moreover, the materials of the PCB terminals being cut (steel, stainless steel, copper, zinc, tin, iron, etc.) vary in terms of softness, hardness, thickness, and fineness, which naturally dulls the cutting edges of the lead cutting machine blades after a period of use.

Therefore, tungsten steel cutting blades need to be reground after a certain period of use. Based on our more than ten years of experience in lead cutting machine blades, it is best to choose the water grinding method for sharpening the cutting edges (avoid dry grinding as much as possible). Water grinding serves a cooling function, which can to some extent reduce or minimize the thermal fatigue of the blades during grinding, thus maintaining their original characteristics.

To fully utilize the wear resistance, sharpness, and long lifespan of tungsten steel cutting blades, it is recommended, whenever possible, to choose water grinding for the blade edges. This will help improve production efficiency and reduce production costs.

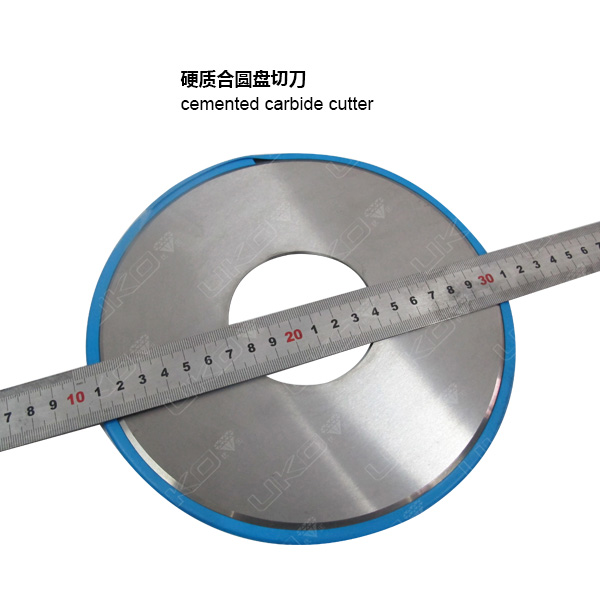

Common specifications of carbide lead cutting blade

Product Specification 1: φ200×φ70×3.5 (commonly known as 8-inch small blade)

Product Specification 2: φ250×φ70×3.5 (commonly known as 10-inch large blade)

Packaging methods

Option 1: Aluminum box packaging, 1 blade per box, with hard foam padding inside for better protection of the sharpness of tungsten steel cutting blade edges. This packaging method also facilitates logistics and transportation. The advantage is excellent product protection, but the cost is relatively higher.

Option 2: High-density compressed cardboard box packaging, 1 blade per box, with hard foam padding inside for better protection of the sharpness of tungsten steel cutting blade edges. This packaging method also facilitates logistics and transportation. The advantage is lower cost, but the product protection is relatively lower compared to aluminum box packaging.

The role of carbide?lead cutting blades

1Lead cutting machine blades are made of carbide, and their material composition includes various carbide?powders, such as tungsten carbide (WC), titanium carbide (TiC), tantalum (niobium) carbide (Ta(Nb)C), vinyl carbide (VC), and binding metal components like cobalt (Co), nickel (Ni), and iron (Fe). Each of these components plays a crucial role in the overall performance of the lead cutting machine blades.

2Tungsten carbide (WC) has excellent toughness and wear resistance.

3TiC exhibits characteristics such as wear resistance, oxidation resistance, and resistance to lunar cratering wear. However, TiC and its solid solutions are much more brittle than WC, resulting in lower alloy toughness. When the TiC content exceeds 18%, the alloy becomes not only brittle but also difficult to weld.

4TaC imparts good wear resistance, toughness, resistance to lunar cratering wear (inferior to TiC), and high-temperature performance (improved high-temperature strength, high-temperature hardness, and oxidation resistance) to the alloy. Adding TaC helps reduce the friction coefficient, thereby lowering the tool temperature. The alloy can withstand large impact loads at high cutting edge temperatures. However, TaC is extremely expensive and cannot be used in large quantities. It is commonly used for removing thermal welding tumors.

5VC, besides serving as the main component in the alloy, is often added as an additive. Its main functions include reducing the sensitivity of alloy performance to sintering temperature and time, expanding the range of sintering temperature and time that meet the requirements for magnetic properties (Hc) and hardness (HRA), inhibiting the growth of carbide grains during sintering, altering phase composition to improve alloy heat resistance. The additive can widen the two-phase region of WC-Co alloys, reduce the sensitivity of alloy performance to carbon, enhance the alloy’s resistance to lunar cratering wear, reduce chipping, and improve chip-breaking performance.

Precautions for using carbide?lead cutting blades

1Before installing the blades, please take necessary precautions to prevent injuries and avoid unnecessary personal and property damage. 1.1. Sound Check: When installing the blades, carefully lift the blade with the index finger of your right hand, allowing it to hang freely. Then, lightly tap the blade body with a wooden hammer and listen attentively to the sound produced. If the blade emits a dull sound, it indicates that the blade has been damaged by external impact, such as cracks or damage. Such blades should be immediately discarded. Do not use lead cutting machine blades that produce a dull sound!

2Blade Installation: Before installing the blades, thoroughly clean the dust, chips, and other debris from the bearing mounting surface of the lead cutting machine to keep it clean. 2.1. Carefully and steadily place the blade on the bearing mounting surface and rotate the lead cutting machine’s bearing by hand until it automatically aligns with the center of the blade. 2.2. Install the pressure block onto the blade, aligning the bolt holes of the pressure block with the bolt holes on the lead cutting machine’s bearing. 2.3. Insert the hexagon socket head cap screw and tighten it firmly with an Allen wrench to secure the blade to the bearing. 2.4. After blade installation, there should be no looseness or deviation.

3Safety Protection: After blade installation, before starting the lead cutting machine, make sure to install the safety guards and other protective devices properly to ensure effective protection (the blade working area of the lead cutting machine should be equipped with safety shields, steel plates, rubber, or other protective layers).

4Operating Speed: The working speed of the lead cutting machine should be limited to below 4500 RPM. Over-speed operation of the machine is strictly prohibited.

5Test Run: After the blades are installed, run the machine without load for 5 minutes and carefully observe and listen to the operation of the lead cutting machine. There should be no obvious looseness, vibration, or abnormal noises (such as significant axial and end face runout of the lead cutting machine’s bearing). If any abnormality occurs, immediately stop the machine and have it inspected by a professional technician. Only after confirming that the issue has been resolved and the machine is functioning normally can it be used.

6During the cutting process, feed the circuit boards to be cut at a steady and uniform speed, avoiding rapid and forceful pushing. Violent collisions between the circuit board and the blade can cause blade damage (breakage or cracking) and even serious safety accidents.

7Blade Storage: It is strictly prohibited to use electric engravers or other methods to write or mark on the blades to prevent damage to the blade body. Lead cutting machine blade edges are extremely sharp but fragile. To prevent injuries or accidental damage, do not touch the blade edge with your body or other metal objects. Unused blades should be properly stored and handed over to specialized personnel, rather than casually left unattended, to prevent blade damage or accidents.

8Safety is a prerequisite for production efficiency. Lead cutting machine operators must adhere to the relevant usage requirements to ensure the safe operation of the blades on the lead cutting machine.