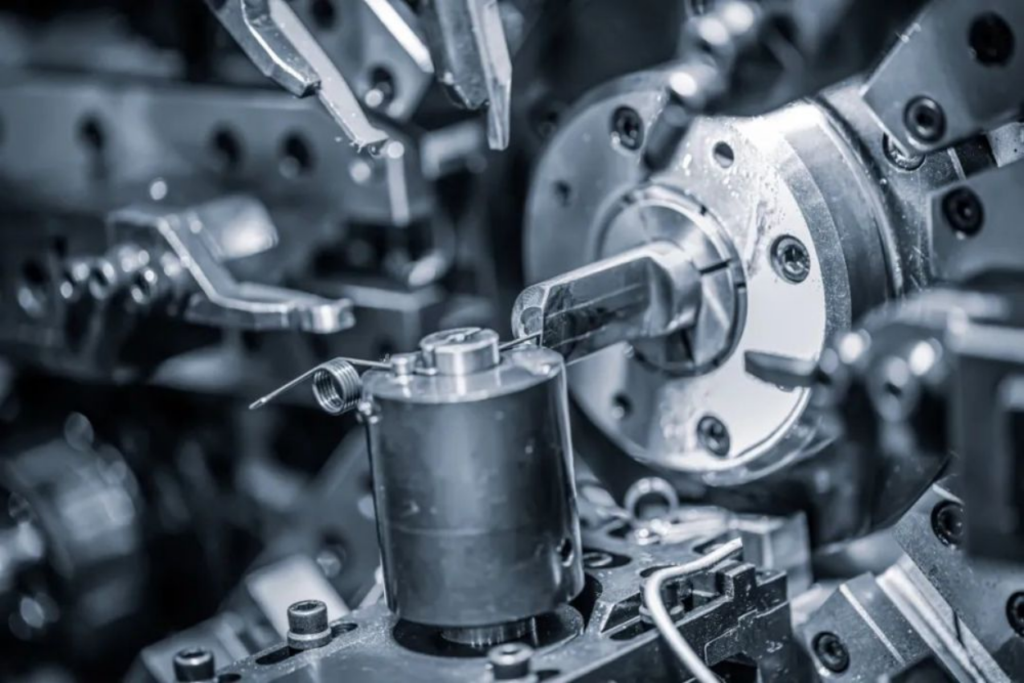

Edge radius processing is an indispensable process after fine grinding of CNC tools and before coating. The purpose is to make the cutting edge smooth and smooth, and extend the tool life. There are 9 methods of edge radius treatment of CNC tools introduced by Meetyou. Let’s get to know it.

Edge radius?treatment of the cutting tools of the machining center refers to the process of leveling, polishing and deburring the cutting tools, including edge passivation, chip removal groove polishing and coating polishing.

1. Resistance to tool physical wear

In the cutting process, the tool surface will be gradually consumed by the workpiece, and the cutting edge is prone to plastic deformation under high temperature and high pressure. The passivation treatment of tools can help improve the rigidity of tools and avoid premature loss of cutting performance of tools.

2. Maintain the smoothness of the workpiece

Burrs on the cutting edge of the tool will cause tool wear, and the surface of the machined workpiece will become rough. After passivation treatment, the cutting edge of the tool will become very smooth, the phenomenon of edge collapse will be reduced accordingly, and the surface finish of the workpiece will also be improved.

3. Convenient groove chip removal

Polishing the tool groove can improve the surface quality and chip removal performance. The smoother the groove surface, the better chip removal will be, and more consistent cutting can be achieved.

After passivation and polishing, the tools of CNC machine tools will leave many small holes on the surface. These holes can absorb more cutting fluid during machining, which will greatly reduce the heat generated during cutting and greatly improve the cutting speed.

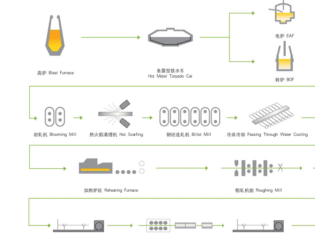

9 kinds of edge radius processing methods

Grinding wheel edge radius?method

This is the earliest and most widely used passivation technology.

Nylon brush?edge radius?method

it is a common method to coat the abrasive medium of fine particles on the brush wheel or brush disc of nylon material, and re move the cutter through the high-speed rotation of the brush.

Sand blasting method

it is divided into dry sand blasting and wet sand blasting. It is also a common method of edge radius processing. Compared with nylon brush method, this process accomplish?a higher consistency of edges.

Stirring method of edge radius processing

This method is to put the whole tool into the abrasive bucket before treatment, and position the depth of the tool through the laser sensor to ensure the quality of treatment. The blade consistency of this process is also higher than that of nylon brush method.

Electrochemical mechanical edge radius processing

This is a composite process that combines electrochemical machining and mechanical grinding. First, electrolytic deburring, and then mechanical grinding to remove oxide film.

Laser method: it is a passivation technology developed on the basis of laser cladding technology. It can produce high heat on the blade surface by laser, melt some materials, and achieve the effect of passivating the blade.

Vibration edge radius processing method

the main processing device includes a vibration table and a worktable. The blade is placed in a container that is connected with the vibration body. The container is filled with abrasive particles. The abrasive particles and the blade repeatedly collide to remove trace materials on the cutting edge through collision to achieve edge passivation.

Magnetic abrasive method

This is a edge radius processing that applies a magnetic field in the direction perpendicular to the axis of the cylindrical surface of the workpiece, and adds magnetic abrasive between the magnetic field S and N poles. The magnetic abrasive will be adsorbed on the magnetic pole and the workpiece surface, and will be arranged into a flexible “abrasive brush” along the direction of the magnetic line of force. The cutter rotates and vibrates axially at the same time to remove the metal and burrs on the workpiece surface.

Micro abrasive water jet technology: a new and environment-friendly processing technology, which forms a liquid-solid high-energy jet through the control of the pressurizer and nozzle diameter, and realizes passivation treatment by high-speed and repeated collision on the workpiece.