Agricultural equipment is a major investment and its replacement parts should not cost more than the equipment itself. However, this doesn’t mean that a part should be of inferior quality. In most cases, there are alternatives that offer better performance. There are a variety of third-party manufacturers that produce high-quality agricultural equipment replacement parts.

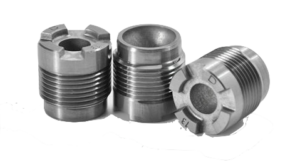

Agricultural wear parts must be strong and durable to work under harsh conditions. They are typically designed to be forged or cast and made of high-strength materials. Our parts are made from tungsten carbide, which is one of the hardest materials on earth.

We can produce all kinds of carbide plates, tiles, and teeth for agriculture tool parts for different applications like Rumpstad, Tine Fit, Cultivator, Shredder Knives, etc.

OEM and special designs are also accepted.

Standard Grades

| Grade | Binder content | Hardness (HRA) |

Density (g/cm3) |

T.R.S (MPa) |

| YG6 | 6%Co | 91 | 14.6-15.0 | 1600 |

| YG8 | 8%Co | 89 | 14.4-14.8 | 1800 |

| YG6x | 6%Co | 92 | 14.6-15 | 1850 |

| YG13 | 13%Co | 90.5 | 14.1-14.5 | 1950 |

| YG15 | 15%Co | 91 | 14.0-14.2 | 2450 |

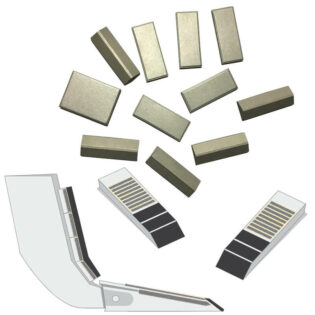

Tungsten carbide snow plow inserts are placed into milled grooves along the bottom wear surface of the cutting edge giving it unmatched wear-resistant properties and making snow plow blades ideal for high-speed highway or airport runway plowing.

Tungsten carbide snow plow inserts are placed into milled grooves along the bottom wear surface of the cutting edge giving it unmatched wear-resistant properties and making snow plow blades ideal for high-speed highway or airport runway plowing.