Multi-source presses have multiple independent hydraulic sources, meaning they have several independent working cylinders. An example is the hexahedral press, which has six working cylinders connected to each other by hinge beams. On the other hand, a single-source press has only one hydraulic source, commonly referred to as a two-sided press. While the previous discussions have focused more on hexahedral presses, let’s talk about two-sided presses today.

Chinese manufacturers of high-pressure, high-temperature products primarily use hexahedral presses, whereas those in Europe and America predominantly use two-sided presses. The earliest research and production of products such as diamond, CBN, PDC, and gem-grade cultured diamonds were achieved on two-sided presses. Therefore, it can be said that two-sided presses play an irreplaceable role in the production of ultra-high-pressure products.

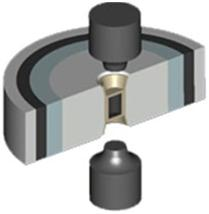

Different from hexahedral presses, two-sided presses apply pressure on both sides of the ultra-high-pressure mold, such as ring-type devices and concave die devices.

Characteristics of the two-sided press

(1) The two-sided press is a single-source press with cylinders located in the lower part of the frame. This structure uses cylinders with larger diameters, resulting in lower working pressure and relatively longer cylinder lifespan.

(2) The main machine and hydraulic system have a simple structure, low maintenance rate, and are easily scaled up.

(3) Between the hammer and the pressing cylinder of the two-sided press, there are guides for fixtures and sealing bowls, ensuring high precision, simple material loading and unloading, and easy implementation of automation.

(4) During the synthesis in the two-sided press, with the support of the?w?glik?pressing cylinder, as the hammer advances, the sealing and pressure-transmitting bowl gradually becomes thinner, and the core rod gradually thickens. Compared to the assembly and high-pressure characteristics of the hexahedral press, there is very little overflow inside the assembly chamber, resulting in minimal deformation of the core rod.

(5) The separation of pressure sealing and heat insulation allows for independent adjustment of pressure sealing, pressure transmission, and chamber insulation functions.

(6) Uniform changes in insulation throughout, consistent deformation of the heater, small variations in the temperature field, and easy adjustment of the temperature field.

(7) Small internal pressure fluctuations, high pressure transmission efficiency, excellent linear characteristics in internal pressure transmission, easy pressure calculation, and strong adjustability in pressure utilization due to simple assembly adjustments.

(8) Under high-temperature and high-pressure conditions, the core rod undergoes simple and uniform thickening. This makes it easy to achieve flatness in products with high requirements for surface finish, such as large-diameter PCD/PCBN composite sheets, after synthesis.

(9) The two-sided press, equipped with characteristics such as moderate high-pressure stroke, good pressure stability, and excellent synthesis repeatability, allows the temperature and pressure fields in the synthesis chamber to remain stable for a long time. It is suitable for growing high-grade diamonds and other products.

Limitations of the two-sided press

(1) The carbide pressing cylinder has a high mass, and its hardness and toughness requirements are demanding, leading to production difficulties and high costs. During the synthesis process, the dimensions of the carbide pressing cylinder change rapidly, necessitating regular inspections of its size.

(2) The carbide pressing cylinder is highly stressed, leading to a short overall lifespan, significant consumption, and higher costs.

(3) The mold system of the two-sided press requires high standards. Multiple layers of steel rings or multiple layers of steel rings combined with flat steel wires are used to protect the carbide pressing cylinder in the mold. This approach must ensure sufficient rigid support for the pressing cylinder while minimizing bending deformation during high-pressure conditions. Otherwise, the lifespan of the pressing cylinder is extremely short. The technical content of mold design, calculation, and manufacturing is high, with stringent requirements for the hardness and dimensions of each component.

(4) During the synthesis process, the two-sided press has a large hammer stroke, long sealing sides, slow pressurization and depressurization speeds, resulting in longer single-synthesis times and lower efficiency.

(5) The design of the sealing and pressure-transmitting sides and the coordination of internal assembly components are crucial. When designed improperly, various issues such as explosions, increased deformation of the pressing cylinder, shortened hammer lifespan, and lower pressure utilization efficiency may occur.

(6) Strict requirements for the dimensions of assembled components, with some parts requiring adjustments based on changes in the pressing cylinder’s size.

(7) Difficulty in temperature and pressure measurements.

Certainly, many of the concerns mentioned above also apply to hexahedral presses, but the emphasis may vary.

Wniosek

The main machine and hydraulic system of the two-sided press have a simple structure, resulting in a very low maintenance rate, and it is easy to achieve automation and scalability for large-scale operations. Its assembly characteristics determine uniform temperature distribution, easy adjustability, high pressure utilization efficiency, and easy adjustment of the pressure. The deformation of the core rod after synthesis is minimal, making it particularly suitable for the production of high-pressure and high-value-added products such as gem-grade cultured diamonds, high-grade large-diameter PDC, PCBN, PCD drill bits, and other products with stringent pressure requirements.