Brief history of WC carbide

Cemented carbide, born in 1923, emerged from a legendary and awe-inspiring nation – the Germanic people.

In the late 19th century, in search of new materials to replace high-speed steel and further enhance metal cutting speed, reduce processing costs, and solve issues like tungsten wire drawing for light bulbs, people began exploring the production of cemented carbide products.

In 1893, German scientists heated tungsten trioxide and sugar together in an electric furnace to high temperatures, successfully producing tungsten carbide. They attempted to utilize its high melting point and hardness to create wire drawing dies, as a substitute for diamond materials. Unfortunately, due to the brittleness, susceptibility to cracking, and low toughness of tungsten carbide, the first exploration of cemented carbide was declared a failure.

Entering the 1920s, German scientist Karl Schroter studied and discovered that pure tungsten carbide could not withstand the intense stress changes occurring during the drawing process. Only by adding low-melting-point metals to WC could the blanks possess a certain level of toughness without compromising hardness. Schroter proposed a method of powder metallurgy, mixing tungsten carbide with a small amount of ferrous metals (iron, nickel, cobalt), then pressing and sintering the mixture at temperatures exceeding a thousand degrees Celsius, resulting in the birth of the world’s first cemented carbide.

The continuous pursuit of cemented carbide with higher hardness and greater toughness led to the development of advanced production equipment for cemented carbide. In 2005, a team led by Professor Zhu Min from South China University of Technology in China introduced cold plasma into mechanical ball milling. By ball milling W, C, and Co powders with plasma, they were able to directly sinter the pressed green compacts into high-performance cemented carbide, achieving a one-step method for preparing high-performance and controllable W-C-Co cemented carbide.

The production of traditional hard alloys

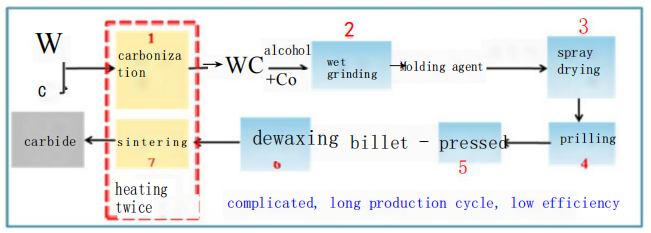

The production process of traditional WC-Co cemented carbide is generally complex. It involves the reduction of tungsten oxide, carburization of tungsten, wet grinding of the mixed powders, drying and granulation of the mixed powders, compact pressing, debinding, and sintering. Clearly, this production process is intricate and has a relatively long production cycle. It also requires two high-temperature processes for carburization and sintering, resulting in high energy consumption, as shown in Figure

fig1:The production of WC-Co carbide using traditional industrial methods

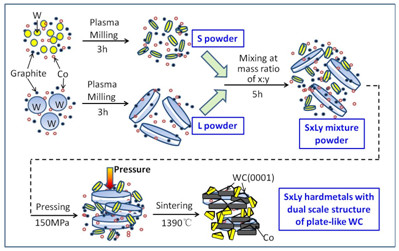

The utilization of low-temperature plasma-assisted high-energy ball milling (dielectric barrier discharge plasma-assisted milling, abbreviated as plasma milling) equipment has enabled the efficient refinement and activation of W-C-Co powders in a short period of time. Experimental results have confirmed that the composite powder obtained after discharge plasma milling (≤3 hours), when pressed and formed, can be directly sintered into WC-Co cemented carbide at around 1390°C, as shown in Figure 2.

fig2:The one-step method for preparing WC-Co carbide, based on dielectric barrier discharge plasma-assisted milling technology

Compared to the traditional process of cemented carbide preparation, this method (carburization-sintering one-step method) avoids the drawbacks of the two high-temperature stages in the traditional process. It enables the synthesis of WC and the densification of WC-Co alloy bodies in a single step. This method is a new approach characterized by a short preparation process, simplified procedure, and low energy consumption. By utilizing this method and controlling the grain size and morphology of WC, as well as the arrangement state of plate-like WC, a novel high-performance cemented carbide with a dual morphology and dual-scale structure has been successfully prepared.

The one-step method for synthesizing carbide through carbide sintering

The one-step synthesis of cemented carbide is based on the discharge plasma-assisted ball milling technology. Firstly, the original W, C, and Co powders are subjected to plasma ball milling to produce nanocrystalline W-C-Co composite powder. The ball milling time is approximately 1-3 hours. Then, the prepared composite powder is cold pressed and formed into green compacts. Finally, the green compacts are carburized and sintered in a vacuum or low-pressure sintering furnace to obtain WC-Co cemented carbide bodies in a single step, as shown in Figure 2. The cemented carbide typically prepared by this method is a high-performance nanocrystalline or ultrafine-grained WC-8Co alloy.

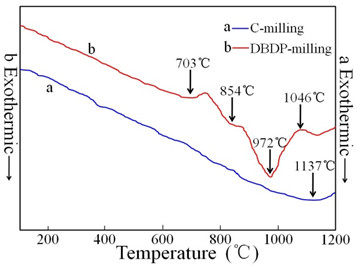

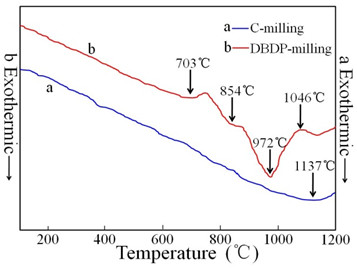

Figure 3 shows the DSC curves of W-C mixed powders milled for 3 hours using conventional ball milling and plasma-assisted ball milling. After plasma-assisted ball milling, the W-C mixed powder starts to form WC at around 900°C (the new plasma-assisted ball milling equipment can achieve WC synthesis below 800°C). This temperature reduction of 300-500°C compared to conventional carburization methods significantly shortens the carbonization process by tens to hundreds of hours compared to commonly used ball milling times.

fig4:After 3 hours of plasma-assisted milling: (a) W-C powder; (b) morphology of W-C powder after sintering at 1000°C; (c) morphology of W-C powder after sintering at 1390°C.

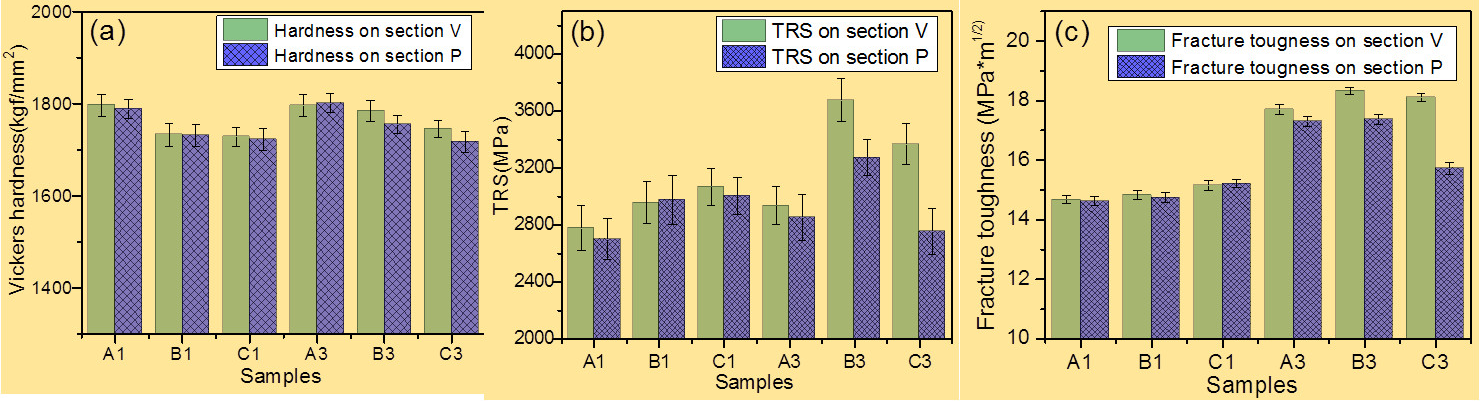

It is highly meaningful that WC-8Co carbide prepared using the “one-step method” process exhibits excellent mechanical properties, as shown in Figure 5.

fig5:The mechanical properties of WC-8Co carbide prepared by plasma-assisted milling with different scales

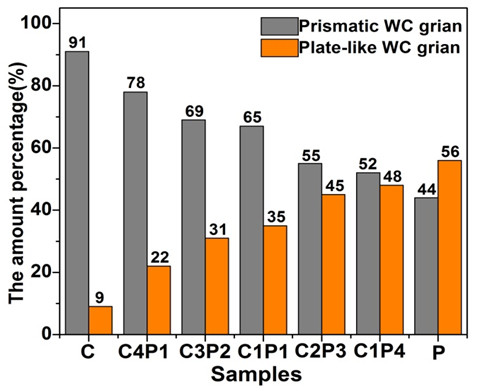

Based on the “carburization-sintering one-step method,” by adjusting the plasma ball milling time, it is possible to obtain cemented carbide with a combination of plate-like and prismatic WC in different proportions. When an appropriate proportion of plate-like and prismatic WC is achieved, the cemented carbide exhibits improved overall performance. This is because plate-like WC possesses good flexural strength, while the presence of prismatic WC effectively avoids the issue of lower transverse rupture strength (TRS) caused by highly oriented arrangement of plate-like WC on the cross-section.

The synergistic effect of the two different forms of WC ensures the uniformity of the mechanical properties of the cemented carbide and effectively enhances its comprehensive mechanical performance. For example, for WC-8Co cemented carbide prepared by vacuum or low-pressure sintering, when the percentage of plate-like WC is around 35%, its hardness is HRA92.1, and the transverse rupture strength (TRS) is approximately 3800 MPa.

Therefore, the development of the “carburization-sintering one-step method” for preparing WC-Co cemented carbide using plasma ball milling technology enables the microstructural control of WC in multiple forms and scales. This approach facilitates the production of high-hardness and high-strength WC-8Co cemented carbide.

High-performance dual-phase, dual-scale WC carbide

WC crystals belong to the hexagonal crystal system. The anisotropy of the hexagonal system results in different physical and mechanical properties of WC grains in each crystallographic direction or plane. The hardness of the WC (0001) basal plane is twice that of the WC (10-10) plane. When a certain amount of plate-like WC is present in cemented carbide and its distribution state is controlled by exploiting the anisotropy of plate-like WC grain properties, dual-phase cemented carbide with better performance than conventional cemented carbide can be prepared.

In the study of the effect of WC morphology on cemented carbide performance, it has been discovered that by carefully adjusting the plasma ball milling process, control of WC morphology as prismatic or plate-like (lamellar) can be achieved in the subsequent sintering process, as shown in Figure 6.

fig6:Cold cylindrical and plate WC morphologies of different scales prepared by plasma ball grinding

Based on this foundation, the design and preparation of dual-phase cemented carbide with dual-phase WC grains have been achieved by adjusting the processing methods. The different morphologies of WC on different cross-sections demonstrate that the morphology of WC can be controlled to be either prismatic or plate-like by adjusting the ball milling time. In the study of the effect of plate-like WC content on improving mechanical properties, the proportion of different forms of WC in the cemented carbide matrix and the arrangement state of plate-like WC have been controlled through rational design.

Currently, while maintaining high hardness in the obtained WC-8Co cemented carbide, controllability in terms of strength has been achieved. The mechanical properties of the cemented carbide mainly include hardness = 91.5 ~ 93.0 HRA, TRS = 3300 ~ 4000 MPa, and KIC = 17.5 ~ 21.5 MPa*m1/2.

As shown in Figure 7, the content of different WC morphologies in a series of dual-phase cemented carbides and the mechanical properties listed in Table 1 indicate that the typical example C1P1 of dual-phase cemented carbide has a plate-like WC content of approximately 35%. The mechanical properties of the cemented carbide on different cross-sections are as follows: hardness on the cross-section = 92.4 HRA, TRS = 3795 MPa; hardness on the longitudinal section = 92.1, TRS = 3824 MPa. This indicates that the synergistic effect of the two different forms of WC not only ensures the uniformity of the mechanical properties of the cemented carbide on different cross-sections but also effectively improves its comprehensive mechanical performance.

fig7:Variation in the content of columnar and lamellar WC in dual-phase WC carbide

chart1:Hardness and TRS (tensile strength) of dual-phase WC-8Co carbide (corresponding to Figure 7).

In further research on the preparation of high-content plate-like WC cemented carbide, by selecting the particle size of the original tungsten (W) powder and employing a rational preparation process, the degree of orientation of plate-like WC can be well controlled, leading to a significant improvement in the transverse fracture strength of the cemented carbide, as shown in Figure 8.

fig8:The process route for preparing dual-scale plate-like WC-Co carbide using plasma-assisted milling technology

In the current stage of research, the WC-8Co cemented carbide containing a high proportion of plate-like WC exhibits excellent mechanical properties, with the following optimal mechanical performance: cross-sectional hardness = 92.4 HRA, transverse rupture strength (TRS) = 4083 MPa, longitudinal hardness = 92.1 HRA, and TRS = 3924 MPa.