Due to its high hardness and wear resistance, tungsten carbide is widely used as a variety of processing tool materials, known as “industrial teeth”. Among them, WC Co tungsten carbide is the largest production and consumption of tungsten carbide materials. After decades of development, in the engineering application of tungsten carbide , the hardness and wear resistance can basically meet the requirements of service performance, while the fracture strength and impact toughness are the bottleneck of expanding the application of tungsten carbide , especially the high-end application. For a long time, there is a lack of systematic understanding about the strengthening and toughening mechanism of tungsten carbide , which is a kind of metal ceramic dual phase composite and multi-phase composite material with additives. The relationship between multi-component, structure, mechanical behavior and comprehensive performance of this kind of material system needs further study.

1.scientific problems

At present, the common basic research scientific problems in the field of tungsten carbide from engineering application can be summarized as follows:

in the industrial preparation of ultrafine and nanocrystalline tungsten carbide , the grain growth must be controlled by adding grain growth inhibitors. However, inhibitors usually have adverse effects on the toughness and strength of tungsten carbide . It is necessary to fully understand the stability control factors of inhibitor derived microstructure and the effects on the microstructure and mechanical properties of tungsten carbide .

With the decrease of the grain size of the hard phase below the submicron scale, the internal interface gradually becomes the main factor affecting the toughness and strength of the tungsten carbide . However, the factors that can stabilize the WC / CO and WC / WC boundaries and the mechanism of the stabilization are not well understood, and the formation and evolution mechanism of the low-energy interface are not well understood.

Through the study of the mechanical behavior and micro mechanism of tungsten carbide at room temperature and high temperature, the understanding of the strengthening and toughening mechanism in the service process can be deepened, so as to guide the design and preparation of high-performance tungsten carbide . At present, there is no systematic understanding of the micro deformation mechanism, the source of plasticity and the high temperature mechanical behavior of tungsten carbide .

2.Research progress

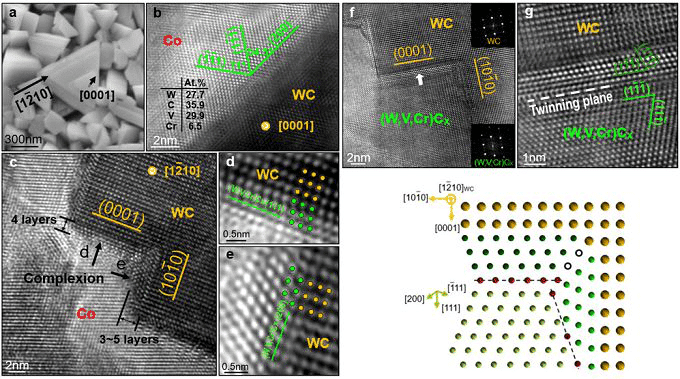

Professor Song Xiaoyan’s team of Beijing University of technology has carried out a series of basic researches on the practical problems in the engineering application of tungsten carbide . In 2013, the research team first prepared nanocrystalline tungsten carbide block materials with high density and uniform structure, which have both high hardness and high toughness, and put forward the interface coherent toughening theory of nanocrystalline two-phase tungsten carbide (ACTA mater. 2013, 61, 2154-2162), which has been fully verified in in-situ mechanical experiments (mater. Res. lett. 2017, 5, 55-60). Recently, combining theoretical modeling and experimental design, the research group has deeply studied various “interface structures” that may appear in tungsten carbide materials, and found several kinds of interface structures with 2-6 atomic layer thickness, influencing factors, stabilization approaches and micro mechanisms. Based on the optimization of additives and fine-tuning of composition, the accurate control of the stability of interface structure is realized. The mechanism of anti intergranular fracture of phase interface matching materials with various elements such as V, Cr, Ti, Ta and Nb is proposed. Furthermore, the influence of interface structure stability and surface energy anisotropy on the formation and evolution of ∑ 2 and ∑ 13A at low energy boundaries was obtained by optimizing the inhibitors of grain growth and controlling the Sintering Densification temperature. Thus, the controllable preparation problem of increasing the ratio of WC / CO coherent phase boundary to WC / WC low-energy grain boundary distribution in tungsten carbide is solved. Relevant achievements were successively published in Acta mater. 2018, 149, 164-178 and Acta mater. 2019, 175, 171-181 under the titles of “complexions in WC Co tungsten carbide s” and “l(fā)ow energy grain boundaries in WC Co tungsten carbide s”. Guided by the basic research, the research group and the enterprise cooperated to prepare the ultra-high strength and high toughness tungsten carbide bars with the average transverse fracture strength of more than 5200mpa and fracture toughness of more than 13.0mpa · M1 / 2. The fracture strength value is the highest performance index of fracture strength among the similar tungsten carbide reported in the world.

In addition, the research group has done a lot of research on the relationship between the microstructure, mechanical behavior and comprehensive properties of tungsten carbide . In the aspect of experiment, the microstructure evolution of tungsten carbide under external loading, especially the dislocation and stacking fault motion law, was realized through in-situ mechanical experiment.

With the help of fine structure characterization and crystallography analysis, the interaction mechanism of crystal defects of hard phase and ductile phase in high strength and toughness tungsten carbide was proposed, and the mechanism of its effect on delaying crack nucleation and resisting crack growth was revealed. Especially, in view of the strain behavior of tungsten carbide , it is proposed that the main slip system of WC phase can produce dislocation of compression bar at room temperature, while the activation of new slip system at high temperature can provide plastic contribution, which quantitatively reveals the relationship between the plastic strain of tungsten carbide and the movement of slip system and dislocation as well as the change rule with temperature. In the aspect of simulation calculation, the mechanical behavior of bicrystal and polycrystal tungsten carbide at room temperature and high temperature was studied by molecular dynamics method, and the micro mechanism of the influence of grain boundary, phase boundary, intragranular defect and grain size on the deformation and fracture behavior of tungsten carbide was clarified on the atomic scale. On the electronic scale, the electronic density of state and bonding form of WC are calculated and analyzed by the first principle, and the micro mechanism of high hardness of WC is clarified.

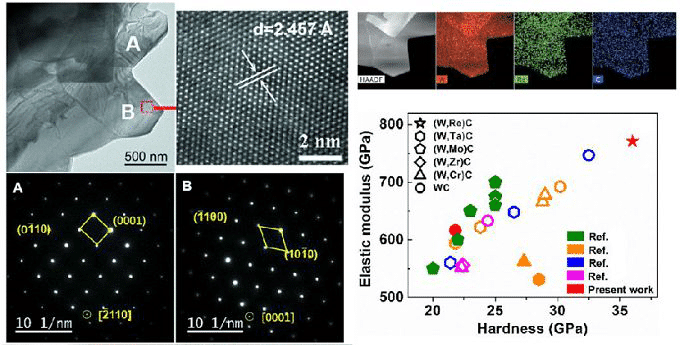

It is proposed that the elastic modulus and hardness of WC can be further improved by micro solid solution of metal elements with high work function, and then higher hardness re solid solution unbonded phase WC bulk material is successfully synthesized in the experiment. In 2019, the above research progress was published in three consecutive articles in the international well-known journal crystal Journal: Acta crystal. 2019, B75, 134-142 (the first author is Fang Jing, master’s student); Acta crystal. 2019, B75, 994-1002 (the first author is Dr. LV Hao); Acta crystal. 2019, B75, 1014-1023 (the first author is Hu Huaxin, doctoral student). On the meso and macro scale, a finite element model based on the real three-dimensional structure of tungsten carbide is established. The heterogeneous strain response and plastic deformation behavior of tungsten carbide under the interaction of as prepared residual thermal stress and external stress in the bearing process are studied. The relationship between microstructure deformation behavior fracture toughness is revealed. This achievement was published in int. J. plasticity, 2019, 121, 312-323 (the first author is Dr. Li Yanan).

Figure 1. Interface structure and evolution characteristics of WC / CO phase boundary formed by adding VC and Cr3C2

Figure 2. Effect of additives, temperature and surface energy anisotropy on the formation and evolution of low energy grain boundaries in tungsten carbide

Figure 3. Effect of WC grain rotation on micro plastic deformation in nanocrystalline tungsten carbide

Figure 4. Microstructure and mechanical properties of a new type of high hardness WC block material with re unbonded phase

Figure 5. Typical dislocation reactions (including dislocation decomposition, the formation of compression bar dislocations, etc.) on the WC base plane and the main slip plane on the cylinder

Figure 6. Effect of inhomogeneous strain response on fracture behavior of tungsten carbide during compression