Many little friends have a feeling that no matter how fine the garlic is, it doesn’t have the smell of mashed garlic. I believe it’s true as long as it’s eaten.

The main reason for this is that the chopped garlic is not as fine as the mashed garlic. In the process of mashing garlic, because the garlic is subjected to the irregular impact of external force, it will destroy each cell wall of garlic. It is the process of squeezing juice that makes the garlic aroma fully released, so it will make the mashed garlic more garlic flavor.

In modern industrial production, it is often necessary to crush, grind and refine some materials for use. For example, some ores need to be crushed and screened after mining in order to continue fine processing, and some even require the particle diameter of ore crushed to reach the fineness level of mm.

Under normal circumstances, the crushing of rock can be completed by a crusher, but this can only crush and roughly grind the rock. In order to finely grind the rock to a finer degree, it is necessary to use the mechanical equipment of ball mill and rely on the ball milling process.

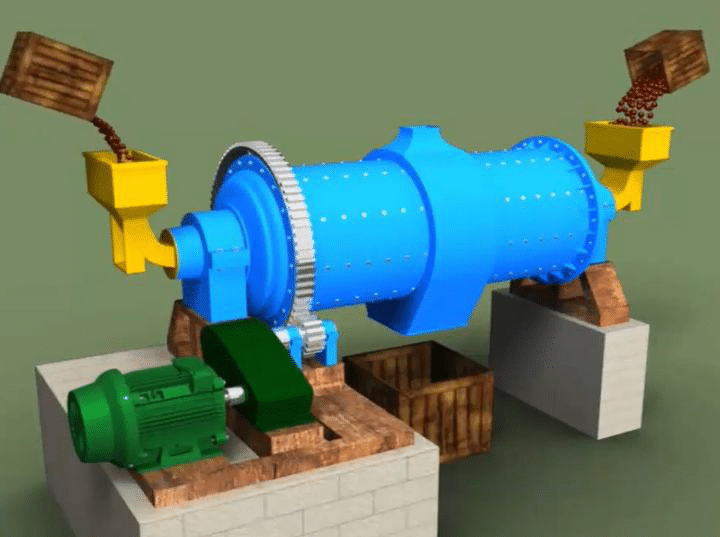

Ball mill

The ball mill is a device that destroys the raw materials again after they are mined or broken into small pieces to make their particles smaller. From its name, it can be understood that the ball mill is equipped with steel balls in a closed cylinder. Through the rotation of the cylinder, the steel balls fall from high places and collide with the materials to be pulverized, so as to achieve the purpose of grinding and thinning the materials.

Ball mills are widely used in the production of new building materials, cement, refractories, non-ferrous metals and glass ceramics.

The ball mill has the characteristics of high production efficiency, environmental protection, low grinding cost, continuous production, and wet and dry grinding of different raw materials.

Ball milling mode

Ball mills can be divided into dry ball mills and wet ball mills according to different working methods. Different ball milling methods are used according to different industries and material characteristics.

Dry ball milling is to directly transport materials to the mill and grind the raw materials by the impact of the steel ball through the rotation of the mill. It is mainly used to crush and grind some materials that will react with water, such as cement and marble. In addition, dry ball milling will also be used in places with water shortage or high requirements for environmental protection.

Wet ball milling is similar to dry ball milling, except that a certain proportion of water or absolute ethanol should be added according to different materials in the grinding process. It is mainly used for materials that will not affect the quality in the presence of water, such as non-ferrous metal ores such as gold, copper and copper.

Principle of ball milling

Usually, in the upstream of a river, you can see some large and not very round stones. In the middle reaches, you can see some round pebbles, and in the downstream, you can see a lot of fine sand, which is caused by the scouring of water flow and the collision of stones under the action of water flow.

Similarly, the grinding of materials is completed by impact in the process of ball milling, but this process will be much more complex. For example, when a single material is ball milled, because a single material will be impacted by many steel balls in this process, the existing or new cracks on the material surface will become larger or expand, and finally lead to crushing into countless smaller materials.

When these small materials are crushed again, countless smaller material particles will be produced. Each crushing of materials will increase the number of new biological material particles by geometric multiple. Each reduction of material particles is caused by crack crushing after being impacted by external force.

However, when these new material particles reach a certain size, it is difficult to break and split again. This is also because the surface cracks will become thinner and smaller as the material particles become smaller. If they need to be broken, greater impact force is required, that is, the finer the material particles, the more difficult it will be to break them.

Therefore, the crushing process of seemingly simple materials is very complex. Large materials are cracked and broken after being subjected to the impact force, and those smaller material particles are broken by the collision between the particles due to the impact force.

Ball milling process

The ball mill is mainly composed of cylindrical cylinder, hollow shaft, main bearing, feeding and discharging hollow shaft, motor, transmission gear and other parts.

There are many lining plates in the cylinder, which can not only protect the cylinder, but also raise the steel ball to a certain height, so as to improve the grinding efficiency. The cylinder is also equipped with a certain number of round steel balls with different diameters, which is the most important medium in the crushing and grinding process. Therefore, the steel ball is also called “grinding medium”.

When the materials are fed into the horizontal cylinder, the motor drives the large gear ring to rotate and drive the cylinder to rotate. The materials and steel balls in the cylinder will adhere to the inner wall of the cylinder under the joint action of inertia, friction and lining plate blocking, and will be lifted with the rotation of the cylinder.

When the cylinder is lifted to a certain height, the materials and steel balls will be thrown down due to the action of gravity, and some steel balls will fall on the materials and break them. With the continuous rotation of the cylinder, the materials and steel balls will rise and fall in a circular motion, and they will rub and squeeze each other in the process of material rising, which can also achieve the effect of grinding.

The impact force generated when the material falls and the air flow in the cylinder will generate axial thrust, which will flow small materials to the discharge end, so as to complete the process of crushing and grinding.

There is a saying called “a good cuisine is to be well prepared “. The seemingly coarse, large and stupid ball mill can also crush and grind all kinds of materials into millimeter sized particles, and the materials are no longer limited to those ores and cement.

Now some small ball mills have been used in laboratories, pharmaceutical industries and other high-tech material industries, and have gradually become the preferred equipment in the development of some new materials.