The traditional method for producing coarse-grained WC?involves the following steps: WO? is reduced at high temperature to obtain coarse tungsten powder, which is then subjected to high-temperature carburization to produce coarse-grained WC. The WC produced by this process is approximately 22μm in size. This method has dominated the domestic industry for a long time.

Development of Production Methods

In the past decade, there have been continuous updates in the manufacturing methods of coarse-grained WC?powder, including:

method 1 for coarse-grained WC Powder

High-temperature carburization of medium or fine tungsten powder: This process can produce coarse WC grains with a particle size of 7-8μm.

method 2

MACEO (Microplasma-Assisted Chemical Etching of Oxygen) method: This process can produce extremely coarse WC powder with a sieve size larger than 40 mesh. However, it requires special treatment and impurity purification before being used for manufacturing carbides.

method 3

Cobalt-nickel carburization method: This process utilizes a small amount of cobalt and nickel to accelerate the carbide formation of tungsten particles and promote rapid growth of WC grains. With this mechanism, coarse-grained WC with a particle size of 22μm can be produced at relatively low temperatures.

method 4

Classification of coarse-grained WC powder: This method involves using techniques such as cyclone separation, fluidized bed classification, liquid elutriation, or sieving to separate large particles containing W?C and free carbon from WC. This not only narrows the particle size distribution range but also improves the quality of WC powder by increasing the compound carbon content and reducing the free carbon content.

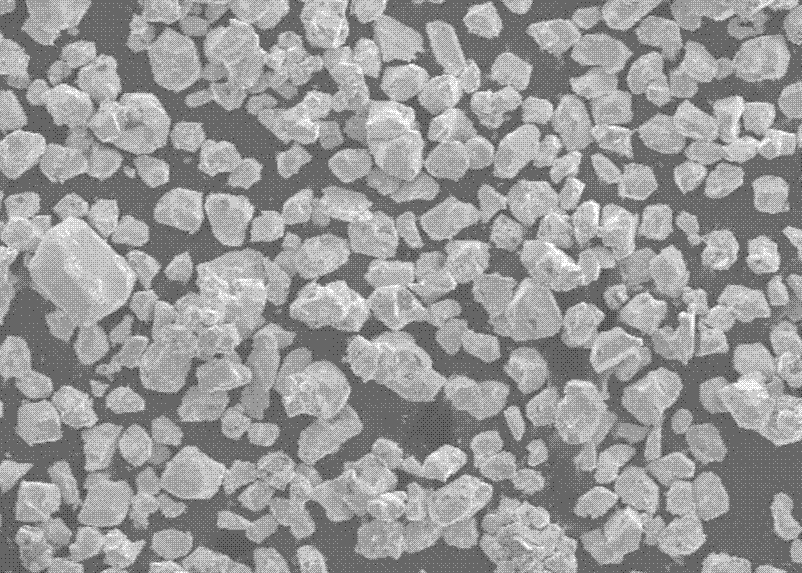

As the application scope of coarse-grained WC?continues to expand, the demand for coarse carbide with a particle size larger than 22μm cannot be met. Therefore, it becomes necessary to develop new coarse-grained WC?products with a particle size greater than 30μm. After several years of exploration, we have successfully experimented with the additive method to produce coarse-grained WC?powder with a particle size larger than 30μm. This method has the advantages of a simple and feasible process, easy operation, utilization of existing production lines without the need for additional equipment, low process temperatures that save energy and prolong the lifespan of process equipment, and high purity of the produced product with no residual additives. The particle crystallization is intact, and the particle size distribution is uniform, consistent with the normal production of WC for carbides.

Experimental Method and Results

The experiment utilized blue tungsten oxide, produced by our factory, as the raw material. After uniformly adding the additive, it was subjected to continuous hydrogen reduction in a furnace at temperatures ranging from 900 to 1100°C, resulting in the production of tungsten powder (W). After carbonization with appropriate carbon content, the tungsten powder was further subjected to a one-hour carbonization process at around 2000°C in a continuous direct-heating carbon tube furnace. The coarse-grained WC?powder was obtained after ball milling and crushing.

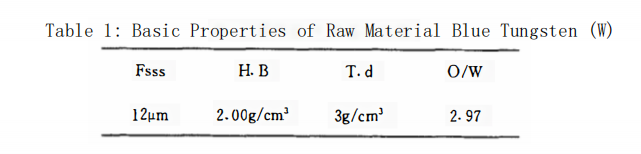

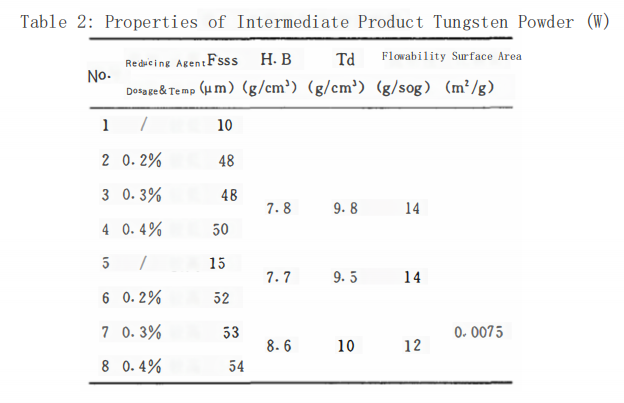

The properties of the raw material, blue tungsten (W), are shown in Table 1. The properties of the intermediate product, tungsten powder (W), can be found in Table 2. The properties of the final product are presented in Table 3.

Using 1# WC with approximately 10% Co in the conventional process, the performance of the produced carbide?is as follows: strength of 2560 N/mm2, hardness of 86.5 (HRA), density of 14.42 g/cm3, magnetic flux density of 5300 A/m2, and WC grain size of 3.5 μm.

Analysis of Experimental Results

The above experimental results demonstrate that the additive used in the reduction and carbide formation processes of tungsten significantly increases the grain size of tungsten powder and tungsten carbide particles. As a result, various physical properties of tungsten powder and tungsten carbide powder undergo significant changes.

Compared to products without the additive, the addition of the additive can increase the particle size of tungsten powder by 3.5 to 4.5 times and the particle size of tungsten carbide powder by 2.5 to 3.0 times. Within the scope of the experiment, the process temperature has a significant influence on the particle size of tungsten powder and tungsten carbide. However, the variation in additive content does not have a significant impact on the particle size of tungsten powder and tungsten carbide powder.

Preliminary Exploration of Activation Mechanism

The experimental results indicate that the additive promotes the growth of WC particles, mainly during the tungsten reduction stage. However, during the carbide formation process, the particle size of the product does not increase and, in fact, slightly decreases.

It is well known that the reduction of blue tungsten (primarily composed of WO?go) to tungsten powder undergoes several stages: WO?go → WO?n → WO? → W. During the WO?go → WO? stages, the product generally maintains the particle morphology of its precursor. However, during the WO? → W stage, almost all particles undergo a significant change in morphology and there is a considerable variation in particle size. This can be attributed to two main reasons: first, the solid-state phase transformation during the reduction process leads to particle fracture and refinement; second, the volatilization → reduction → deposition mechanism causes particle coarsening.

We believe that the presence of the additive not only enhances the volatilization → reduction → deposition process by creating an additional channel for the formation of WOxnReO(gas), but also suppresses particle fracture during certain solid-state phase transformations that occur during the reduction process. This further exacerbates the coarsening and refinement of intermediate reduction products. As a result, the additive increases the base number of tungsten powder particles that undergo growth and intensifies the cycle of re-oxidation → volatilization → reduction → deposition of fine tungsten powder particles. This is the mechanism by which the additive activates and promotes the growth of tungsten powder particles during the reduction process.

Summary and Current Issues In this study

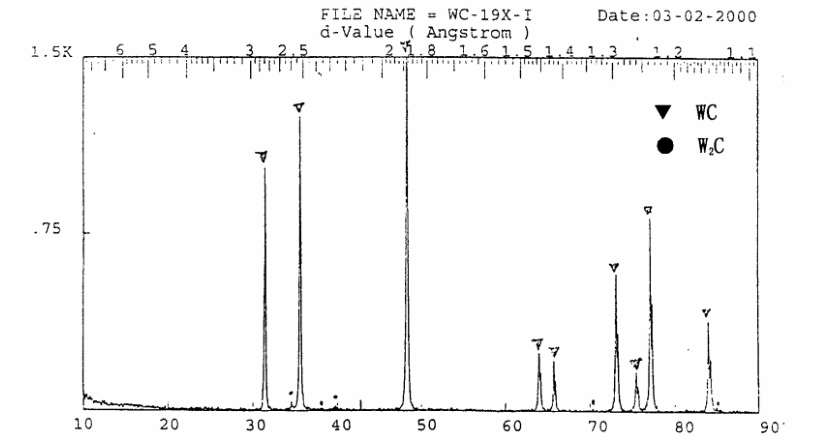

it is observed that the carbide process conditions for tungsten powder described in the paper are not entirely optimal. As a result, some of the coarse particles in the final product of WC powder contain W?C inclusions in their cores, accounting for approximately 2.4% of the total particles, as shown in Figure 1. Therefore, further improvements are required in the carbide process to ensure its suitability for the production of carbides.