Austenitic stainless steel has good corrosion resistance because of its high chromium content and dense oxide film. When Cr18% and Ni8% are contained, a single austenite structure can be obtained. Therefore, austenitic stainless steel has good corrosion resistance, plasticity, high temperature performance and welding performance. However, under different working conditions, austenitic stainless steel welding joints often face some special problems, which are easy to cause construction defects such as intergranular corrosion, stress corrosion, knife corrosion, welding hot cracks, α phase embrittlement and so on.

Corrosion analysis of welded joints

Intergranular corrosion of welded joints

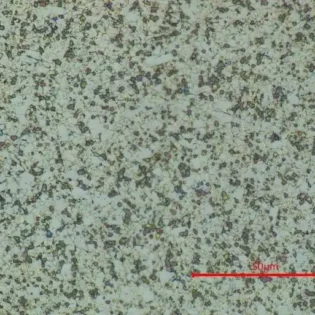

Intergranular corrosion is one of the most important corrosion problems of austenitic stainless steel. Once intergranular corrosion occurs, its strength will almost lose when it is serious, and intergranular fracture will occur when a certain stress is applied. The intergranular corrosion of austenitic stainless steel welding joint is mainly caused by chromium carbide precipitation. When the austenitic stainless steel is sensitized in the temperature range of 500 ~ 800 ℃, the diffusion rate of supersaturated solid solution carbon to the intergranular boundary is faster than that of chromium, and the carbon in supersaturated solid solution is combined with chromium near the grain boundary, When the chromium content in the region is reduced to below the limit content (w (CR) 12.5%) required for passivation, the corrosion of the region will be accelerated and intergranular corrosion will be formed. The results show that the intergranular corrosion in the sensitized temperature zone of HAZ occurs in the region where the peak heating temperature is between 600 ℃ and 1000 ℃. The reason for intergranular corrosion is still the precipitation of chromium carbide at austenite grain boundary. The main preventive measures to reduce and prevent intergranular corrosion include:

① Small specification (small current, high welding speed) and multi pass welding are adopted;

② The carbon content in the base metal and welding material should be reduced as much as possible, and the welding material with C content less than 0.03% should be used;

③ As a result, Cr diffuses to the grain boundary more quickly in ferrite than in austenite, which reduces the phenomenon of poor chromium in austenite grain boundary;

④ The addition of Ti, Nb and other elements with stronger affinity to carbon than chromium in steel and welding materials can form stable compounds with carbon bonding, thus avoiding chromium depletion at austenite grain boundaries.

Stress corrosion of welded joints

The stress corrosion cracking of stainless steel is the most harmful corrosion behavior. There is no deformation when cracking. The accident is often sudden and the consequences are serious. There are many factors influencing the stress corrosion cracking of stainless steel under service conditions, including the composition, structure and state of the steel, the type of medium, temperature, concentration, stress properties, size and structural characteristics.

The main measures to reduce and prevent stress corrosion are as follows:

① Avoid strong assembly, mechanical impact and arc burn, reduce cold work deformation and stress;

② Strictly control impurities in media and environment (especially chloride, fluoride, etc.);

③ Reasonable material selection (base metal, welding material): avoid grain coarsening and hardening martensite structure;

④ The weld is well formed without any stress concentration (such as undercut);

⑤ Arrange welding sequence reasonably to reduce stress;

⑥ Anti corrosion treatment: add corrosion inhibitor to coating, lining or cathodic protection.

Hot crack sensitivity analysis of welded joints

The hot cracks of austenitic stainless steel are mainly crystalline cracks, which are produced during the solidification process of liquid metal of weld metal. At this time, primary crystals exist in eutectic melting point, mainly between dendrites. The main reasons are as follows:

① S, P, C and so on form low melting point eutectic with Ni (for example, the melting point of NIS + Ni is 644 ℃), which weakens the grain boundary strength;

② Austenitic stainless steel has the advantages of large distance between liquidus and solidus, long crystallization time, strong dendrite orientation and easy to produce segregation of impurity elements;

③ The thermal conductivity of steel is small, and the linear expansion coefficient is large, so it is easy to produce stress.

The main measures to prevent welding hot cracks include:

① The contents of harmful impurities sulfur and phosphorus in base metal and welding material shall be strictly controlled;

② About 5% ferrite is produced in the weld, which disturbs the direction of austenite columnar crystal;

③ Small current and fast welding process are adopted.

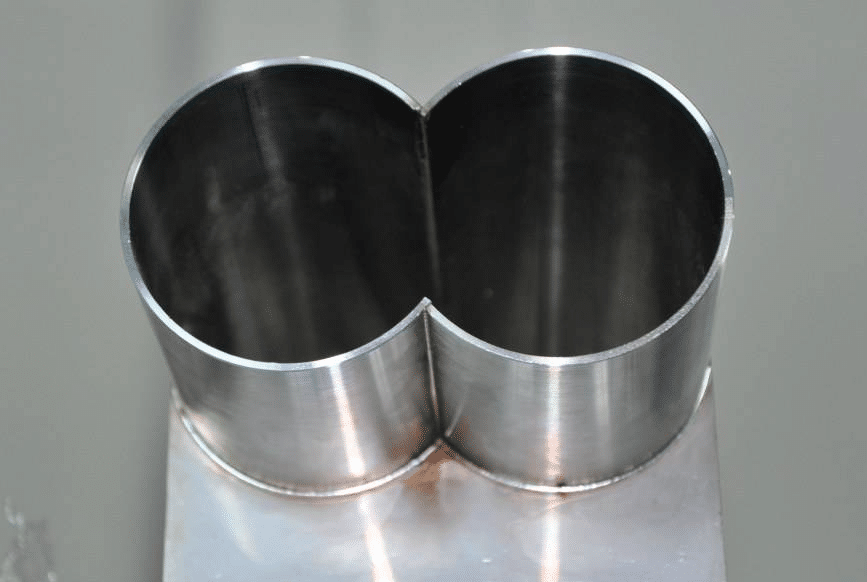

Control of ferrite content in welded joints

The content of ferrite in weld metal of austenitic steel is not only related to the formation and thermal strength of α (σ) phase embrittlement, but also directly affects the hot cracking resistance of joint. The longer the heating time, the longer the high temperature residence time, the more precipitation, which will seriously affect the mechanical properties of the joint. From the point of view of hot cracking resistance, a certain amount of ferrite is required in the weld metal. However, considering the α phase embrittlement and thermal strength, the lower the ferrite content is, the better. Therefore, the content of ferrite must be strictly controlled for high temperature strength welded joints. In some cases, austenitic weld metal must be used.