Experimental Method

Recycled WC powder with a Fisher particle size of 3.00~10.00 μm and normal WC powder with a Fisher particle size of 10.00~18.00 μm were mixed with Co powder or Ni powder with a loose packing density of 0.5~0.7g/cm3 to prepare mixtures of grades YJ1, YJ2, N309, etc. The mixtures were shaped, degummed, and then sintered in a domestically produced horizontal vacuum furnace and a low-pressure hot isostatic pressing furnace manufactured by a German specialized equipment company. The low-pressure hot isostatic pressing process is as follows: loading → vacuum pumping → heating → maintaining sintering temperature → charging argon and pressurizing → maintaining pressure and temperature → cooling and depressurizing → unloading. Electron microscopy was used for metallographic analysis, and the linear shrinkage and shrinkage rate of the samples during the sintering process were measured by the low-pressure hot isostatic pressing sintering furnace to analyze the densification process. The test alloys were made into D43×22 straight horseshoe bits for calibration tests in mining operations.

Experimental Results

Comparison of Properties

Between Low-Pressure Hot Isostatic Pressing Treatment of Recycled Material and Vacuum Sintering Treatment of Normal Material. The two types of tungsten carbide powders, recycled and normal, were processed using the same manufacturing process, undergoing vacuum sintering and low-pressure hot isostatic pressing treatment, respectively. The results are listed in Table 1.

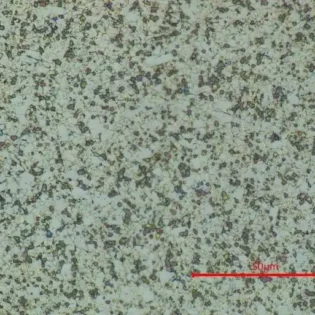

As can be seen from Table 1, the porosity of the alloy treated with low-pressure hot isostatic pressing using recycled WC powder is even lower than that of the normal alloy, and its performance has been significantly improved, with an increase in the transverse rupture strength value; moreover, the elimination of type B pores ranging from 10 to 25 μm indicates the intrinsic relationship between the reduction in porosity and the increase in transverse rupture strength, while also confirming the capability of low-pressure hot isostatic pressing sintering to eliminate pores in recycled alloys.

Low-Pressure Hot Isostatic Pressing Alloy Linear Shrinkage Test

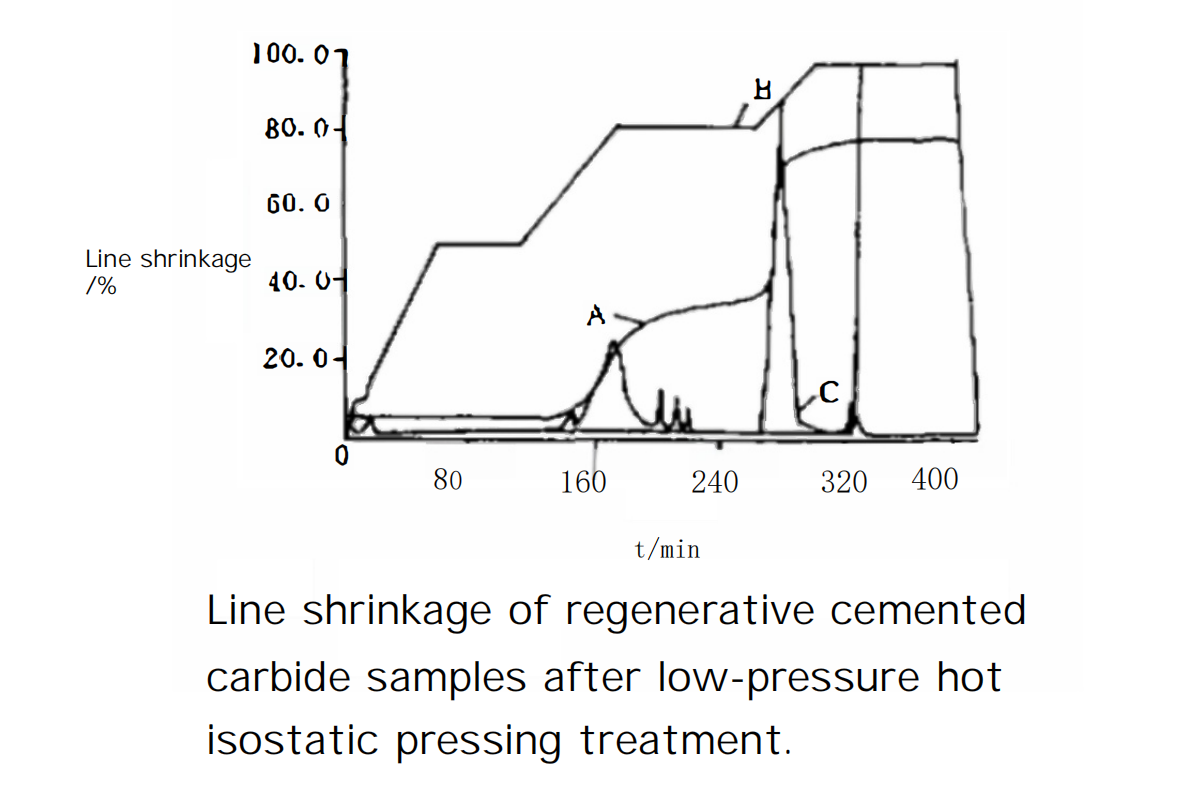

The linear shrinkage and shrinkage rate of the samples during the sintering process in the low-pressure hot isostatic pressing furnace were measured as shown in the attached figure. The alloy undergoes two stages: vacuum sintering and hot isostatic pressing. The macroscopic pores are eliminated during the vacuum sintering stage, and the microscopic pores are eliminated during the hot isostatic pressing stage to achieve the final densification level.

Comparison of On-site Rock Drilling Effects

The two types of tungsten carbide?powders, recycled and normal, were made into alloys of grades YJ1, YJ2, N309, etc., and calibration tests were conducted at the Taolin Lead-Zinc Mine. The results are listed in Table 2.

The rock drilling calibration indicates that high-quality mining carbide?can be produced from recycled WC powder through low-pressure hot isostatic pressing treatment, and their performance is comparable to that of mining carbide?made from normal tungsten carbide.

Result Analysis

Process Characteristics of Low-Pressure Hot Isostatic Pressing for Eliminating Pores in Recycled carbide

The densification of carbide?primarily occurs during sintering, where the plastic flow of the binder phase and the rearrangement of WC grains are driven by surface tension. However, under atmospheric or vacuum sintering, a certain amount of porosity always remains after shrinkage densification is complete; this is because when pores are sealed, the stress inside the pores reaches equilibrium with the surface tension of the pores. Additionally, due to the mixed composition of recycled materials and the presence of more harmful impurities, large pores and voids are easily formed during vacuum sintering, leading to issues such as low alloy density, low fracture strength, significant hardness variations, and severe contamination of the alloy. Applying a certain pressure can promote further flow of the binder phase and rearrangement of WC grains, thereby greatly reducing or even completely eliminating these pores or voids.

Study on the Densification Mechanism of Low-Pressure Hot Isostatic Pressing

The change curve of the linear shrinkage rate of recycled carbide?samples during low-pressure hot isostatic pressing sintering is shown in the attached figure. There are three peaks on the shrinkage rate curve: Peak A appears at a sintering temperature of 1200°C, which is solid-phase sintering. Due to the low yield point of the binder phase, plastic flow occurs under a small external force. The flow of the binder metal changes the contact situation between powder particles, causing the carbide?particles to move and come closer together. Peak B appears during the liquid-phase sintering process at 1340°C, where WC particle rearrangement, solution precipitation, and skeleton formation result in significant shrinkage of the sintered body, and macroscopic pores are eliminated during the vacuum sintering process of low-pressure hot isostatic pressing. Peak C appears at the beginning of the pressurization stage, where the rise in pressure eliminates the micro-pores in the product. However, with the extension of the pressure maintenance time, no new shrinkage peak appears in the product.

結(jié)論

(1) The physical and mechanical properties of the recycled alloy treated by low-pressure hot isostatic pressing are superior to those of alloys manufactured by conventional processes, with a significant reduction in porosity and the elimination of type B pores.

(2) The recycled alloy treated by low-pressure hot isostatic pressing does not fall short of normal alloys in on-site rock drilling tests, and its wear resistance is even improved.

(3) The mechanism by which low-pressure hot isostatic pressing improves the performance of the alloy is mainly the elimination of large-sized pores and the reduction in porosity.