TaC?carbide has been?one of the earliest carbide?put into industrial production?since traditional WC-Co carbides can no longer meet people’s demands for higher product quality. TaC is considered to improve the high-temperature performance of carbide. Meetyou Hardmetal Corp. conducted the following experiment, using WC with different particle sizes as the research object, and studying the properties of TaC tungsten carbide?sintered at different temperatures.

Experiment method

The formulation of the carbide?consists of w(Co)=6.0% and w(TaC)=1.85%. In the WC powder, the mass fraction of particles with an average Fechner size of 4.90μm is 44%, and the mass fraction of particles with a size of 0.89μm is 56%.

The ball-to-powder ratio is 4:1, and the mixture is wet-milled in ethanol at a speed of 50r/min for 65 hours in a 160mm diameter ball mill. Then, the powder is pressed into a B-type bar with dimensions of 20mm x 5.4mm x 6.5mm using a rubber processing procedure. The bars are sintered in a vacuum dewaxing furnace at 1425℃, 1450℃, and 1500℃ for 1.5 hours each.

Afterwards, our experimental staff analyzed the microstructure of the material using scanning electron microscopy, measured its density using an analytical balance, measured its Vickers hardness using a Vickers hardness tester (HV30, with a pressure time of 15 seconds), measured its bending strength using a tensile testing machine, and measured its coercivity using a coercivity meter.

Experimental data on TaC carbide

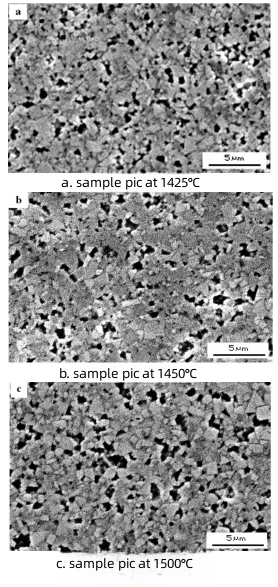

得られたTaC炭化物材料の微細(xì)構(gòu)造を図1に示します。

From Figure 2, it can be seen that at a sintering temperature of 1425°C, the grain size mainly distributed in ultra-fine grains, showing a normal distribution. At a sintering temperature of 1450°C, the grain size was concentrated in adjacent ultra-fine and ultra-submicron grains, accounting for nearly 70% of the total statistics. The number of nanocrystals also reached its highest value.

At a sintering temperature of 1500°C, the grain size mainly distributed in ultra-fine grains, but some grains grew significantly, resulting in a decrease in the proportion of nanocrystals and ultra-submicron grains, and an increase in the proportion of medium-sized and coarse grains, resulting in a more scattered grain size distribution.

Experimental result analysis

The impact of sintering temperature on mechanical properties

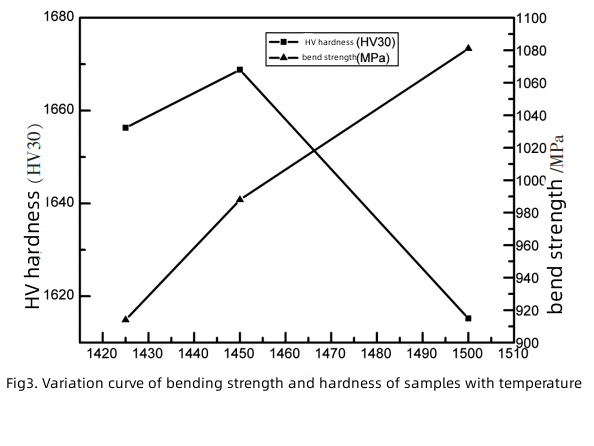

The microstructure and properties of the TaC carbide material obtained are shown in Figure 2, where the bending strength and hardness of the sample increase with the increase of sintering temperature. Therefore, when sintered at 1500°C, the TaC carbide grain size continues to grow. From Figure 3, it can be seen that with the increase of sintering temperature, the bending strength value slightly increases.

The bending strength of the carbide?increases as the uniformity of the WC average grain size improves. When the sample is sintered at 1450°C, the average grain size distribution is uniform, and the bending strength slightly increases. When sintered at 1500°C, the excessively high sintering temperature causes the WC grains to grow through the dissolution-precipitation process, and the increase in grain size is beneficial to improve the bending strength of the carbide. However, overall, the change in bending strength value from 914 MPa to 1081 MPa with the increase in temperature is not very significant.

The effect of sintering temperature on density and coercivity

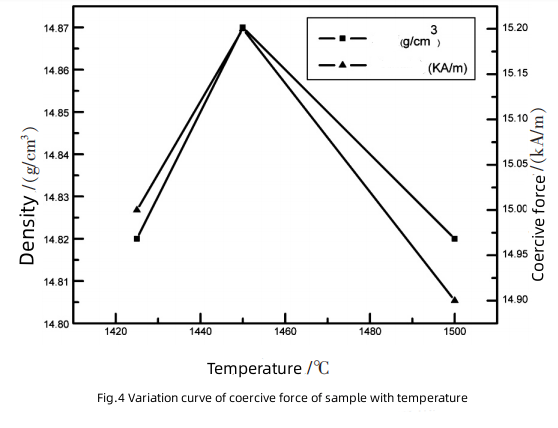

Figure 4 shows the variation curves of density and coercivity of the samples with the change of sintering temperature. Density is one of the important physical properties of powder metallurgical materials, and the change of compact size during sintering is closely related to the change of density.

At 425 ℃ sintering, the shrinkage is incomplete and there are voids present, resulting in a lower density value. With the increase of sintering temperature, the flowability of the bonding phase improves, which is beneficial to eliminate pores and increase the density of the carbide.

When the temperature rises to 1,500 ℃, the volatilization of Co leads to a decrease in the amount of liquid phase, which is not conducive to pore filling, resulting in a decrease in density value.

As for coercivity, in WC-Co carbides, the coercivity is mainly related to the Co content and its dispersion. When non-magnetic η-phase appears in the carbide, the coercivity will increase due to the corresponding reduction in the amount of Co phase and the refinement of WC grains. In carbides with normal microstructure, as the carbon content decreases, the tungsten content in the Co phase increases, which strengthens the Co phase and increases the coercivity. At 1450 ℃ sintering, the grains of the sample are refined and evenly distributed, which maximizes the dispersion of the Co phase and thus maximizes the coercivity.

結(jié)論

In this study, TaC?carbides were prepared using WC raw materials with different particle sizes and sintered at different temperatures. The following conclusions were drawn:

- Under the experimental conditions, the hardness, density, and coercivity of the carbideall first increase and then decrease with the temperature, and the sintering temperature has little effect on the bending strength of the carbide. When sintered at 1450 ℃ and held for 1.5 h, the comprehensive performance of the carbide?is the best, with a Vickers hardness (HV30) of 1668.8, a bending strength of 988 MPa, a density of 14.87 g/cm3, and a coercivity of 15.2 kA/m.

- When using mixed particle size WC, TaC has the best inhibitory effect on WC grain at 1450 ℃.