Causes of Milling Cutter Wear

Milling cutter wear is primarily attributed to two main categories, which are generally complex:

Mechanical Wear

Mechanical wear is induced by intense friction between the cutting chips and the front cutting surface of the tool, as well as the elastic deformation between the tool’s front and rear cutting surfaces and the workpiece surface. This form of wear, termed mechanical wear, becomes the main cause of tool wear when cutting temperatures are not excessively high.

Thermal Wear

During cutting, the intense plastic deformation and friction of the metal generate cutting heat, leading to a reduction in the hardness of the tool edge and a consequent loss of cutting performance, known as thermal wear.

In addition to these two types of wear, several other forms are noteworthy:

- At high temperatures and pressures, adhesion occurs between the tool and workpiece materials, causing adhesive wear, where a portion of the tool material is carried away by the chips.

- At even higher temperatures, certain elements (such as tungsten, cobalt, titanium, etc.) in the tool material diffuse into the workpiece material, altering the chemical composition of the tool’s cutting surface, resulting in diffusion wear.

- High-speed steel tools, under elevated cutting temperatures, experience changes in the metallographic structure of the tool’s surface, leading to decreased hardness and wear resistance, known as phase transformation wear.

- Since each tooth of a milling cutter engages in periodic interrupted cutting, temperature fluctuations during each cutting cycle are substantial, causing thermal shock. Cemented carbide tools, subjected to thermal shock, may develop internal stresses leading to cracking, resulting in thermal crack wear.

- Due to intermittent cutting, milling cutter temperatures are generally lower compared to turning, making mechanical friction the primary cause of tool wear.

Methods for Assessing Tool Wear

Auditory Inspection

Evaluate tool wear during machining by listening for abnormal sounds. Sudden changes in tool sound during processing may indicate wear, requiring experienced judgment.

Visual Inspection

Observe the machining process. If irregular and intermittent sparks occur, it suggests tool wear. Replace the tool promptly based on the average tool life.

Chip Color Examination

Changes in chip color indicate altered machining temperatures, possibly due to tool wear.

Chip Shape Inspection

Irregularities such as sawtooth patterns, abnormal curls, or finer chips than usual suggest tool wear.

Workpiece Surface Analysis

Bright marks on the workpiece surface, with minimal changes in roughness and dimensions, indicate tool wear.

Auditory Monitoring of Machine Vibrations

Increased vibration during machining and unusual sounds may indicate tool wear. Care must be taken to avoid tool breakage.

Machine Load Observation

Significant changes in machine load indicate potential tool wear.

Cutting Edge Assessment

Severe burrs, reduced surface roughness, and dimensional changes in the workpiece are clear indicators of tool wear.

In summary, the combined observation of sight, sound, and touch allows for effective assessment of tool wear.

Methods to Avoid Tool Wear on Milling Cutters

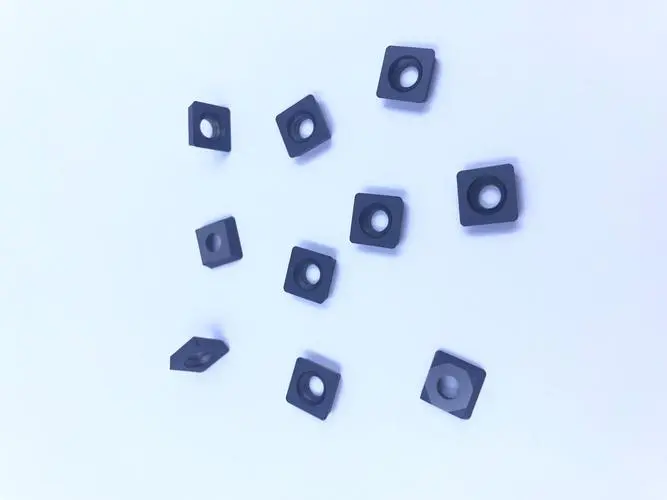

Edge Wear of Milling cutter

Improvement measures include increasing the feed rate, lowering cutting speeds, using more wear-resistant blade materials, and employing coated blades.

Fracture

Measures to address fracture include using materials with better toughness, utilizing reinforced blade edges, ensuring rigidity in the process system, and adjusting the main relief angle.

Thermal Deformation

Strategies to combat thermal deformation include lowering cutting speeds, reducing feed rates, minimizing cutting depths, and using materials with better thermal hardness.

Damage at Cutting Depths

To address damage at cutting depths, adjusting the main relief angle, reinforcing the blade edge, and changing blade materials are effective methods.

Thermal Cracks

Effective strategies involve proper coolant use, reducing cutting speeds, minimizing feed rates, and employing coated blades.

Chip Accumulation

To prevent chip accumulation, increase cutting speeds, raise feed rates, use coated or metal-ceramic blades, and apply coolants to maintain a sharper cutting edge.

Tooth Wear

Mitigation measures include lowering cutting speeds, reducing feed rates, using coated blades or metal-ceramic blades, and employing coolants.

Fracture

To avoid fracture, use materials with better toughness or a groove design, reduce feed rates, minimize cutting depths, and assess the rigidity of the process system.

In conclusion, a comparative analysis of two milling cutters on the same workpiece revealed that selecting appropriate milling cutters and promptly identifying wear not only enhances machining efficiency but also reduces processing costs.