Sintering is the heating of a powder to a certain temperature for a certain period of time and then cooling the material to obtain a product of the desired properties. This whole process of the special heat treatment is called sintering.

Sintering enables porous powder compacts to become the product of a certain texture and properties. Although the attributes of the product are related to many factors prior to sintering, in many cases the sintering process have significant or even dominating influence on the organization and properties of the final product.

According to the classification principle of powder metallurgy on sintering, cemented carbide sintering belongs to the multi-phase liquid sintering. From the perspective of the process characteristics of the sintering process, the sintering of the cemented carbide may be by hydrogen protection, vacuum sintering, hot pressing sintering, hot isostatic pressing, and the like.

Changes in sintered body during sintering

After the sintering of the cemented carbide compact, the most easily observed change is that the volume shrinkage of the compact block, the increased strength, and the surface of the alloy exhibits metallic luster. Typically, the compact has a porosity of about 50%, while the article should generally be less than 0.2%, which is nearly fully dense. Before sintering, the pressing block should also be handled lightly to avoid its damage in the production process.While the sintered products have the strength to withstand various working conditions.

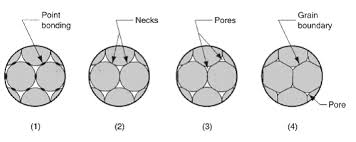

Different from the powder forming process, the change of sinter properties indicates that there are qualitative changes between powder particles in the sintering process, which is that the bonding of alloy grains replaces the contact between powder particles that making the alloy form a solid whole body, thus forming excellent physical and mechanical properties.

Several stages of the sintering process

The cemented carbide sintering process can be divided into four basic stages.

1. Removal of forming agent and pre-burning stage (<800 °C)

In the first stage, the sintering hoop changes as follows:

1) Removal of the forming agent. At the initial stage of sintering, as the temperature increases, the forming agent gradually cracks (such as rubber) or vaporizes (such as paraffin) and excludes the sintered body. At the same time, the forming agent is more or less The sintered body is carbonized.

2) Powder surface oxide reduction. When sintered in hydrogen, hydrogen can reduce cobalt and tungsten oxides. When vacuum sintering, the reduction of carbon at this temperature is not strong.

3) The state of the powder particles changes with each other. At this temperature, the contact stress between the powder particles is gradually eliminated, the bonded metal powder begins to recover and recrystallize, the particles begin to diffuse on the surface, and the strength of the compact is improved.

2. Solid phase sintering stage (800 ° C ~ eutectic temperature)

The eutectic temperature refers to a temperature at which a eutectic liquid phase starts to appear in the sintered body when the temperature is gradually raised, and for the WC-Co, the eutectic temperature at the time of equilibrium sintering is 1340%.

At the temperature before the liquid phase appears, in addition to the process that continues in the previous stage, some solid phase reactions in the sintered body are intensified, the diffusion speed is increased, and the plastic flow of the particles is strengthened, so that the sintered body exhibits significant shrinkage.

3. Liquid phase sintering stage (eutectic temperature ~ sintering temperature)

When the liquid phase of the sintered body appears, the shrinkage of the sintered body is completed quickly, and the carbide grains grow and form a skeleton, thereby laying the basic structure of the alloy.

4. Cooling stage (sintering temperature ~ room temperature)

At this stage, the microstructure and binder phase composition of the alloy change somewhat depending on the cooling conditions. After cooling, an alloy of the final microstructure is obtained.

About hot pressing

Hot pressing is a process in which pressing and sintering are simultaneously performed. In addition to the usual use of resistance heating and induction heating technology, there are also new processes and equipment such as vacuum hot pressing, vibration hot pressing, equalizing hot pressing, isostatic pressing.

1. Densification mechanism of hot pressing process

The process in which the powder of the final addition agent is placed in a graphite stamper so that sintering and pressing are simultaneously performed is called hot pressing.

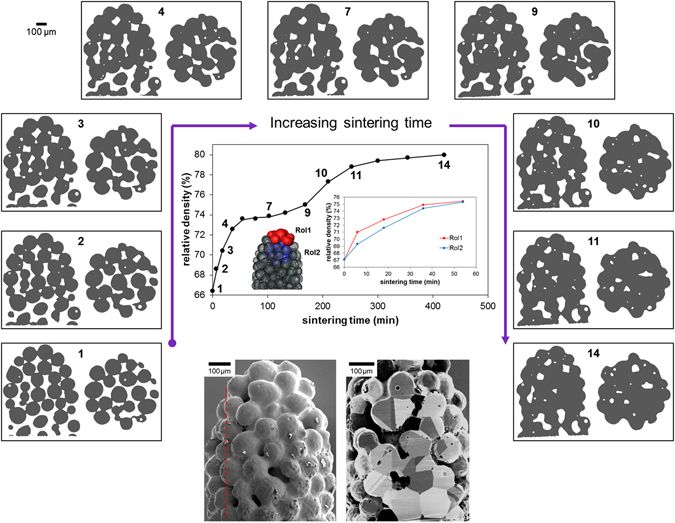

Although the hot pressing is performed simultaneously with the two processes of pressing and sintering, there is no principle difference from the ordinary cold press forming and sintering. From the viewpoint of the effect, the hot pressing greatly shortens the phase transition and the time for forming the alloy. Therefore, it can be said that the hot pressing process is an activated sintering process. The densification process of the alloys produced by the two production methods was compared. From the alloy density–sintering time curve, it can be seen that the sintering process takes 1-2 hours to complete, and it takes only 3 to 10 minutes for hot pressing.

The sintering process during hot pressing is a highly unbalanced process. When the mixture powder is continuously heated under pressure, the oxide film on the surface of the powder is broken under pressure and can be reduced by carbon. However, unlike the sintering process, the hot pressing does not have enough time to balance the solubility of WC in Co, and the recrystallization process through the liquid phase does not occur during the hot pressing process. Therefore, the shrinkage of the hot pressed product is different from ordinary Sintering method.

Besides,some studies have shown that the shrinkage of hot pressed products is caused by the flow process. Before the appearance of the liquid phase, it mainly relies on plastic flow. When the liquid phase appears, the re-alignment of the carbide particles under the action of pressure is also called the liquid phase flow, so that the compact is contracted. Since the hot pressing time is short, diffusion and recrystallization are difficult to carry out.

In addition to temperature and pressure promoting the shrinkage of the sintering process, the holding time also has an effect on the density of the hot pressed product. The higher the temperature, the greater the eye force, the more intense the shrinkage of the compact over time during the onset of hot pressing, and the shorter the time it takes for the density to almost completely cease to change. When a certain holding time is reached, the density of the briquettes will no longer continue to increase, and it will be meaningless to extend the holding time.

In addition, powders with crystal defects can achieve a larger alloy density because the presence of defects can activate the hot pressing process.

2.the characteristics of hot pressing process

The hot pressing process gives its products a unique set of advantages. Therefore, this process plays a major role in the production of cemented carbide. The main feature of this process is.

a.The hot-pressed product has high density and good performance. The porosity of the hot-pressed product is extremely low, and the density almost reaches the theoretical value. At the same time, since the hot pressing time is short, the carbide grains do not grow due to the recrystallization process, so the product carbon is finer than the tungsten crystal grains, which makes the hot pressed product have higher hardness and better wear resistance, especially it is suitable for the manufacture of precision tools such as precision rolls and high-precision wear parts.

b.The pressing pressure is small, and it can produce large-scale products. The unit pressing pressure required for hot pressing is only about one tenth of the cold pressing. Moreover, the size of the product can be expanded by welding, and therefore, the size of the hot-pressed product is limited by the capacity of the press to be less than the cold pressure.

At present, the weight of cemented carbide products produced by hot pressing can reach several tens of kilograms or even hundreds of kilograms.

c.It can produce products with complicated shapes. Due to the hot pressing, the powder materials have thermoplasticity and good fluidity, so they can be made into shaped products with complicated shapes, such as thin-walled tubes and products such as ball cylinders. However, for long pieces, there is still a case where the density is uneven, and the welded long parts are often unevenly welded.

d. It can produce large-size and non-deformed products. The hot pressing method overcomes the shortcomings of cold-pressing and sintering deformation, and can obtain long pieces without bending and hollow products with relatively accurate dimensions. However, due to hot pressing, cobalt is extruded from the surface of the product, which not only causes cobalt loss (1 to 3%) but also makes the surface of the hot-pressed product rough, which is difficult to clean and process.

e. Suitable for single-piece production. Hot-pressing tools are easy to manufacture and have a short production cycle, so they are especially suitable for single-piece or small-volume production that is urgently needed.

f.Low productivity and high cost. The hot pressing method can only produce one to several products at a time. The mold cost is high and the service life is short. Therefore, it is not suitable for large-scale production. It is generally used for the production of cold-sintering method. product.

g. High operating technology is required. During the hot pressing process, the combination of temperature and pressure, temperature rise and cooling rate, and shrinkage control play a decisive role in product performance and defects. Therefore, the operator is required to have a high level of skill.

One thing is noteworthy is that the development of equilibrium hot pressing and isostatic hot pressing overcomes some of the shortcomings of the hot pressing process.