introduction of sintering furnace

The sintering furnace is a kind of furnace which can make the solid particles of the ceramic green body bond with each other, the grains grow up, the voids (pores) and the grain boundaries decrease gradually. Through the transfer of materials, the total volume shrinks, the density increases, and finally it becomes a dense polycrystalline sintering body with a certain microstructure.

principle of sintering furnace

Sintering principle of cemented carbide: the bonding phase, mainly composed of metal (CO, Ni), also known as cermet material, is integrated with ceramic phase (based on tic, TAC, NBC) and the temperature is higher than the bonding phase. The process to achieve this is called sintering process.

purpose of sintering furnace

The sintering furnace is mainly used for the sintering of ceramic powder, ceramic insert and other zirconia ceramics, the sintering of diamond saw blade, and the annealing of copper and steel strip.

The sintering furnace can also be used for high temperature sintering and heat treatment of thick film circuit, thick film resistor, electronic component electrode, LTCC, steel heater, solar panel and other similar products.

Sintering furnace is mainly used in iron and steel industry, metallurgy industry, new material industry, etc.

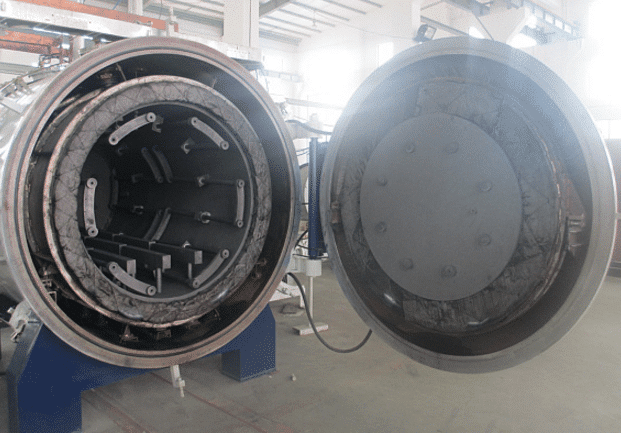

types of sintering furnace

The sintering furnace in the industrial field covers most of the high-temperature polysilicon ingot furnaces in the market. According to the industry, the types of sintering furnaces are mainly as follows:

1.Cemented carbide field:

Vacuum sintering furnace, low pressure (60bar) sintering furnace, vacuum degreasing sintering furnace, low pressure degreasing sintering furnace, low pressure degreasing sintering gas quenching furnace (20bar);

2. Powder Metallurgy:

Continuous mesh belt sintering furnace (1150 degrees), pushrod sintering furnace (1250 degrees), steel belt sintering furnace (1000 degrees), rotary sintering furnace, etc;

3. Solar energy:

Polycrystalline silicon ingot furnace also belongs to a kind of sintering furnace.

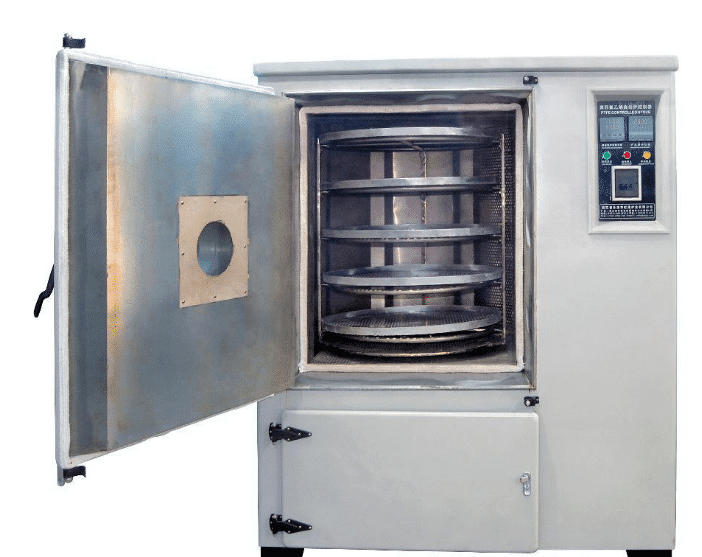

Application of microwave sintering furnace

The key of microwave sintering technology is microwave heating. The principle of microwave heating is to convert the electromagnetic energy of microwave into heat energy by means of electronic polarization, atomic polarization, interface polarization and dipole turning polarization.

Obviously, not all materials can be heated by microwave. According to the characteristics of interaction between matter and microwave, matter can be divided into three categories:

1.Transparent type, mainly low loss insulator, such as most polymer materials and some non-metallic materials, can make part of the microwave reflection and partial penetration, rarely absorb microwave, this kind of material can be in the microwave field for a long time, with very small heat generation, commonly used as the wave permeable material in the heating cavity, such as tetrafluoroethylene, etc., which can be used as the wave permeable partition of the microwave vacuum cavity.

2. The total reflection type is mainly metal materials with good conductivity. The reflection coefficient of these materials to microwave is close to 1, only a small amount of incident microwave energy can penetrate, which can be used as waveguide, microwave cavity, stirrer, etc. in microwave heating equipment;

3. Absorption type is mainly some dielectric materials between metal and insulator, including textile fiber materials, paper, wood, silicon carbide, zirconia, fluorescent powder, ceramics, water, paraffin, etc. the application objects of microwave sintering technology are mainly ceramic materials and metal powder materials.

The characteristics of microwave sintering technology microwave heating has the characteristics of integrity, instantaneity, selectivity, environmental friendliness, safety, high efficiency and energy saving. As a kind of clean energy, microwave has become a research hotspot in the field of materials and triggered a revolution in the field of sintering technology.

Characteristics of microwave sintering:

1. The sintering temperature can be reduced significantly, and the maximum range can reach 500 ℃;

2. Greatly reduce energy consumption, saving energy up to 70-90%;

3. The sintering time can be shortened to more than 50%;

4. Increase the density of the structure, refine the grain and improve the properties of the material;

5. The process is accurate and controllable. Good consistency and stable quality.

Application field of microwave sintering:

1. Ceramic materials:

Using microwave high temperature furnace to sinter all kinds of white porcelain, stoneware porcelain, thin body porcelain and bone ash porcelain can reduce the cost of firing more than half of that of traditional gas fired or oil fired sintering furnace and improve the qualified rate of products.

Using microwave high temperature furnace to sinter red porcelain and blue and white porcelain can greatly improve the yield, shorten the firing time and save energy consumption.

Microwave high temperature furnace can sinter various oxide ceramic materials, nitride ceramic materials, carbide ceramic materials and multiphase ceramic materials, which can greatly reduce the firing time, reduce the firing temperature, reduce product deformation, improve the yield, save energy consumption and reduce production cost.

2. Powder metallurgy materials:

Cemented carbide: the cemented carbide tool sintered in microwave high temperature furnace has realized large-scale industrial production. Due to the rapid sintering, the carbide grains are small, and the product performance can be greatly improved. Various tungsten alloys are sintered in microwave high temperature furnace, and various iron-based and copper-based P / M parts are sintered in microwave high temperature furnace.

3. Magnetic materials:

Compared with the traditional sintering furnace, the frequency characteristic curve of different brand manganese zinc soft ferrite materials sintered in microwave high temperature furnace can obtain better high frequency characteristics under the same proportion.

The results show that the materials sintered by microwave have lower loss and better performance under the condition of the same formula.

4. Microwave synthesis of vanadium nitride and various iron nitride alloy materials:

Microwave high temperature synthesis technology can also be used to mass produce special iron nitride alloys, such as silicon nitride, manganese nitride and chromium nitride iron, which can not only greatly reduce unit energy consumption, but also improve product performance.

5. Microwave high temperature synthesis of various ceramic powder materials:

Various high performance oxide ceramic powders, nitride ceramic powders, carbide ceramic powders and boride powders can be synthesized by microwave high temperature synthesis technology. Including: lithium cobaltite, lithium ferrous phosphate, aluminum nitride, aluminum nitride, Sialon, titanium nitride, vanadium nitride, silicon nitride, silicon carbide, titanium carbide, vanadium carbide, niobium carbide, zirconium carbide, titanium borate, etc. A variety of composite functional ceramic powders and rare earth materials can also be synthesized by microwave high temperature calcination, such as strontium barium titanate, lead zirconate titanate, barium ferrite, yttrium barium copper oxide and long afterglow rare earth luminescent materials.

The ultra-fine and nano-sized inorganic non-metallic powder materials can also be prepared by microwave plasma supersonic powder synthesis technology.

6. Microwave high temperature synthesis of various ceramic pigments, glazes:

Various inorganic non-metallic ceramic pigments and glazes can also be synthesized by high temperature microwave synthesis process: zirconium based pigments: Blue zirconium alum, red zirconium alum, red zirconium iron;

Package color: CD (* * s1-x) – ZrSiO4 package color.

Spinel pigments: zinc chromium iron system, zinc lead chromium iron system, cobalt chromium iron system.