I believe that readers have understood that the basic processing mode of electric hand drill is one of cutting: drilling

However, due to the difference of processing materials and the need of operation efficiency. There are medium power percussion drills and high-power electric hammers and pickaxes. Match the drill bit corresponding to different materials. In order to improve work efficiency. Let me briefly introduce the difference and function between electric drill and drill bit.

I Types of electric drills

| Types of electric hand drill | volt | torque | Fit area | Unsuited area |

| Electric screwdriver | 3.6v-7.2v | 1n-8n | Screw on wood plate below M6 | Drill easy holes |

| Lithium electric drill | 12V | 30n | Screwing and drilling of wood plate and aluminum enterprise screws (less than 10 holes) | Large diameter drill, thick diameter material estimation hole. High hardness material processing |

| Lithium electric drill | 18-20v | 50n-70b | Wood Panel, aluminum alloy, pig iron, Kitchen bathroom wall (holes below 15) | Concrete processing, large aperture processing |

| Percussion drill | 12v | 60n | Wood Panel, aluminum alloy, pig iron, Kitchen bathroom wall (holes below 15) | Concrete processing, large aperture processing |

| percussion drill | 18v-20v | 80n-120n | General materials can be done. even suitable for deep hole processing | No need to add clutch screw |

| Electric hammer and pick | 18v-20v or be plugged in | No torque | Any material will be fine | Don’t fit for fine working |

The table above classifies the voltage, torque and suitable processing materials of various electric hand drills in detail

Law summary: the greater the working voltage of the electric hand drill, the greater the corresponding torque and power, and the higher the hardness of the materials that can be processed.

II The difference between electric drill, percussion drill and electric hammer

Difference between transmission structure and energy conversion ratio (energy conversion ratio)

Differences in movement patterns

1. Difference between transmission structure and energy conversion ratio (energy conversion ratio)

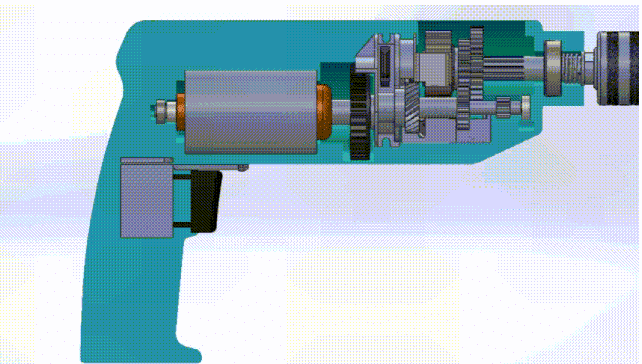

Electric drill the electric drill transmits the kinetic energy of the motor through gear meshing to achieve the rotation effect.

Impact drill the impact drill realizes the impact effect through the dislocation meshing between a fixed gear and a movable gear.

Electric hammer electric pick electric hammer electric pick forms pressure through the reciprocating compressed gas of the cylinder piston to transmit the kinetic energy of the motor.

Energy rotation ratio because electric drill and impact drill are meshed by gears to transmit the power of the motor. There must be gaps in gear meshing, and the kinetic energy of the motor is partially lost in the process of conduction. The electric hammer and pickaxe transmit the kinetic energy of the motor through the cylinder piston, so the viscosity of the gas is small and the resistance is small. The pressure loss is small in the process of flow. In addition, electric hammers and pickaxes are high-power machines, so the processing efficiency is higher than that of electric drills and impact drills. In general, the energy rotation ratio of electric drill and percussion drill is lower than that of electric hammer.

Schematic diagram of electric drill transmission

2. Differences in sports modes

The motion mode of electric drill is essentially drilling. The drill bit rotates, feeds vertically in the axial direction, scrapes off the allowance in a single rotation, and finally opens a hole on the material with the same diameter as the drill bit.

The impact drill adds the impact of high frequency and low Joule on the basis of drilling, and each feed can remove more allowance.

The electric hammer and pick have no function of rotary drilling, only the functions of hammering and impact. The impact of high frequency and high Joule is just like hitting quickly with a hammer, which is suitable for hard work

Schematic diagram of drilling processing

3. Differences of various drill bits

1. Brief introduction to types of drill bits

According to the material and function, the type of drill bit can be explained in a few words. At present, I have no experience in using all drill bits and all materials. If I post all the pictures, I guess everyone won’t have the patience to read them

Woodworking drill can be divided into: woodworking twist drill, support roller drill, hole opener, multifunctional drill for transverse cutting, flat drill and so on

Metalworking (aluminum, steel, pig iron, wrought iron, alloy parts) drills can be divided into: metal twist drill, metal reamer, pagoda drill, stainless steel materials, and a set of special drill hole opening tools

Masonry bit (glass, ceramic tile, marble) can be divided into: triangular bit, impact bit, sample punch bit, glass tile opener, etc

| types | brief introduction |

| Woodworking twist drill | High speed steel, apex angle 118-135 ° |

| Woodworking hole drill | High speed steel, tip for positioning |

| Metal twist drill High speed steel | cemented carbide, apex angle 118-120 ° |

| Triangular bit | Head for alloy steel |

| Impact bit | Special for concrete |

Leave a Reply

Your email address will not be published.