Experimental materials for wet milling and methods

The recycled WC-Co composite powder produced by zinc melting method was used as the experimental material, and its composition is shown in Table 1.

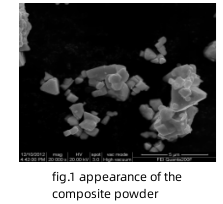

Laser particle size analysis showed that the median diameter was 3.46μm, with a narrow range of particle size distribution and relatively concentrated particle size. Figure 1 shows the SEM image of the original morphology of the WC-Co composite powder.

From Fig.1, it is evident that the recycled powder has mild agglomeration, and its morphology is mostly triangular or rectangular with smooth edges, retaining the characteristics of WC grains in hard alloys. The average particle size of the powder is about 3μm, which is consistent with the results obtained from laser particle size analysis.

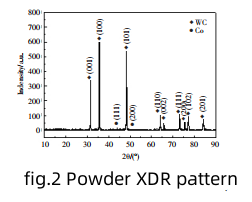

Figure 2 shows the XRD spectrum of the WC-Co composite powder.

Experimental Results and Discussion about wet milling time

Figure 3 shows the morphology of WC-Co composite powders after different wet milling?times. As shown in Figure 3(a), when wet milling?for 18 hours, the powder size is relatively large and unevenly distributed, indicating that the wet milling?effect is not ideal, and the collision between the grinding balls and the powder in the tank is insufficient, and the powder refinement is not enough. After wet milling?for 24 hours (Figure 3(b)), it was found that the powder size decreased rapidly, and the refinement was obvious, but the uniformity was limited. It can be observed that the powder fragmentation mainly occurred due to the repeated impact and friction of the grinding balls, resulting in the rupture of large particles into smaller particles. Continuing wet milling?until 30 hours (Figure 3(c)), it can be found that there is not much change in the powder size, but the uniformity and morphology have improved, with an average particle size between 1 and 2 μm. This indicates that the powder wet ground for 30 hours has a relatively ideal particle size and morphology. Apart from the rupture, the powder is mainly worn out (WC corners are worn out, producing fine powder). Finally, after wet milling?for 36 hours, it is evident that the powder not only did not refine further but also showed agglomeration phenomenon B (see Figure 3(d)).

It should be noted that the powder cannot be infinitely refined during ball milling. During ball milling, as the particle size of the powder decreases, the specific surface area of the powder increases exponentially, exhibiting high surface energy and a sharp increase in reactivity, making it easy to agglomerate and bond with other powders to resist the increase in total energy. As a result, on the one hand, external energy is input into the powder, causing it to refine; on the other hand, the powder agglomerates and forms lumps, reducing the system energy. After the combined effect of these two trends, a dynamic equilibrium is reached between them, and the average particle size of the powder will eventually stabilize within a certain range. In this experiment, the powder was ball milled for 30 hours, and its uniformity was good, with a particle size reaching an equilibrium value (1-2 μm).

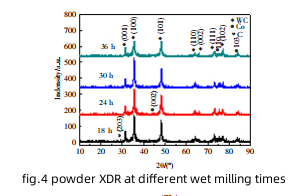

Figure 4 shows the XRD patterns of sintered regenerated cemented carbide with different wet milling times. As shown in the figure, when wet milled for 18 hours, the alloy contains impurity phase of elemental carbon (C); as wet milling continues, the elemental carbon disappears. This indicates that the alloy is slightly carburized during wet milling for 18 hours, and as the wet milling time is prolonged, the powder is refined and the surface adsorbs more oxygen, resulting in an increase in the oxygen content of the mixture. During sintering, part of the carbon is consumed, resulting in the formation of a pure two-phase structure of WC and Co in the alloy, and no other impurity phases were found.

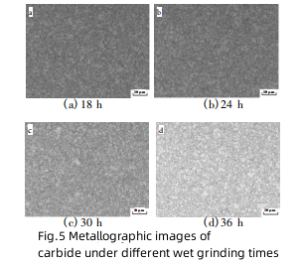

Figure 5 shows the metallographic images of the cemented carbide after corrosion for different wet milling times. Comparing Figures 5 (a) to (d), it can be seen that under the sintering process (1723 K, pressure), the alloy structure is good, and no defects such as abnormally large WC grains and cobalt pools were found. The grain size of the alloy is slightly smaller with a polygonal morphology after wet milling for 24 hours compared to 18 hours, and the Co phase is evenly distributed. As wet milling continues, there is no significant change in grain size, but the uniformity slightly improves. When wet milled for 36 hours, it was found that the WC grains had slightly grown, which may be related to the partial agglomeration of the powder during wet milling.

It is worth noting that as the wet milling?time increases, the strength of the alloy shows a continuous upward trend, but the magnitude of the increase becomes smaller and smaller. Generally, for the same Co content and without obvious defects, the strength of the alloy is related to the distribution of internal micro-pores and WC grain size. When wet milling?for 18 hours, due to the short time, the material mixing is uneven, the powder refinement degree is insufficient, the particle size is large, and the distribution is uneven, resulting in the easy formation of micro-pores during sintering, thus the alloy strength is not high. Continuing wet milling?further breaks down the powder particles, increases the number of fine WC particles, narrows the WC particle size distribution towards homogenization, and eliminates the coarse WC grains, which are the main sources of cracks, resulting in an increase in the bending strength of the alloy.

In WC-Co alloys with the same Co content, the coercive force of the alloy is inversely proportional to the WC grain size and distribution, which is consistent with the description in Figure 5.

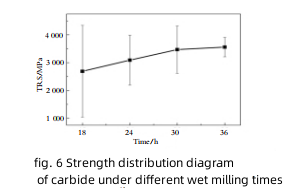

Figure 6 shows the distribution of flexural strength for regenerated cemented carbides with different wet milling times. Based on Figure 6, the range of strength values for each alloy can be observed, which gives the variation of the strength of the statistical samples. It can be seen from the figure that there are many overlaps and dispersions in the experimental results. It is easy to find that with the extension of wet milling time, not only the strength of the alloy increases, but also the fluctuation range becomes narrower, and each strength value is closer to each other. This indicates that the extension of wet milling time can reduce the discreteness of the strength distribution of regenerated cemented carbides.

????????

Under the experimental conditions of this study, the effects of different wet milling?times on the microstructure and properties of recycled WC-8Co composite powder and sintered hard alloys were investigated, and the following conclusions were drawn:

- Continuous wet millingfor 30 hours with a ball-to-powder ratio of 3:1 resulted in fine and uniformly distributed composite powder with an average particle size of 1-2 μm, as observed by SEM.

- Under the conditions of continuous wet millingfor 36 hours with a ball-to-powder ratio of 3:1 and sintering process (1723 K for 1 hour with a pressure of 5 MPa), the alloy exhibited the best comprehensive properties. Its density was 14.71 g/cm3, HRA90.1, the average strength was 3560 MPa, cobalt magnetism was 7.2%, and coercivity was 15.8 kA/m.

- The analysis of the strength distribution of alloys with different wet millingtimes showed that within a certain range, the prolongation of wet milling?time can reduce the discreteness of the strength distribution of recycled hard alloys.