??????? ??? ?????? ?? ??????? ??? ???? ?????, ????? ???????? ????

Selection method of turning tool insert

1 first, determine the main deflection angle of turning tool insert

Among the main deflection angles of conventional turning tool insert, those suitable for finishing machining are generally between 90 ° and 95 °, especially 91 °, 93 ° and 95 °. The main deflection angle close to 90 ° makes the cutting force follow the axial direction of the workpiece, and no force in the vertical direction is applied to the workpiece to avoid vibration and deformation (thin-walled parts processing is particularly important). The main deflection angle is generally guaranteed on the turning tool bar.

2 determine the tool tip angle (turning tool insert shape)

Circular turning tool insert (R type), 90 degree square turning tool insert (s type), 80 degree diamond turning tool insert (C type), 80 degree convex triangular turning tool insert (W type), 60 degree triangular turning tool insert (T type), 55 degree diamond turning tool insert (D type), 35 degree diamond turning tool insert (V type). These turning tool insert shapes basically cover more than 90% of the conventional turning tool insert.

These kinds of turning tool insert are arranged in terms of turning tool insert strength: R, s, C (W), D, V.

The insert strength of R turning tool is the highest and V is the lowest. However, the higher the strength, the greater the resistance and the greater the risk of vibration. Therefore, we often choose R, s, C (W) for rough machining. For finishing, we will choose D and V. V is the best and R is the worst for the profiling capability required for finishing.

3 determine the front angle and rear angle of turning tool insert

The negative rake angle turning tool has good insert rigidity and is not easy to collapse, which is suitable for rough machining, while the positive rake angle turning tool is easy to insert and cut, which is more suitable for finishing machining. There is a matching relationship between the back angle and the front angle. Generally, the insert of the negative front angle turning tool is basically a 0 degree back angle. While the positive rake angle turning tool is inserted with three commonly used rake angle combinations (only turning) of 5 ° (B, ISO code, the same below), 7 ° (c) and 11 ° (P).

Common combinations with turning inserts

CC / CP (C-type positive rake angle turning tool is inserted into 7 ° / 11 ° rear angle), DC (D-type positive rake angle turning tool is inserted into 7 ° rear angle), VC / VB (V-type positive rake angle turning tool is inserted into 7 ° / 5 ° rear angle), WB / WC (W-type positive rake angle turning tool is inserted into 5 ° / 7 ° rear angle). These combinations are also the insert shapes of turning tools used for conventional finishing machining (the front and rear corners are determined)

According to the combination of the three, the insert form of conventional finishing turning tool is as follows:

95 ° main deflection angle turning tool bar + CC turning tool insert

93 ° main deflection angle turning tool bar + WB / WC / DC / VC / VB turning tool insert

91 ° main deflection angle turning tool bar + DC / VC / VB turning tool insert

Among them, 93 ° main deflection angle turning tool bar + DC is the best finishing scheme recommended by individuals (only for turning radial direction). This scheme allocates appropriate cutting parameters and the machining effect should be one of the best in turning at present. The roughness of 1.6 of several different materials has been tested, and the roughness of 0.8 of another steel part is limited by the diameter of the turning tool bar because it is an internal hole. Only the turning tool bar + CC turning tool with a main deflection angle of 95 ° can be inserted.

Of course, the above choice is not unique. Under the condition that the medium and large diameter solid materials can reach the high line speed, the turning tool insert with 0 ° back angle (ISO code n) can also turn out better roughness, but the roughness at this time is more “ground” by the CVD coated turning tool insert with thick alumina at the high line speed. The roughness is basically one grade different from that of the turning tool inserted and processed above. In other words, if the CN turning tool is inserted, it can be finished to 1.6, and if the DC turning tool is inserted, it can be finished to 0.8s

selection of turning tool bar for your insert

Outer diameter finishing turning tool bar

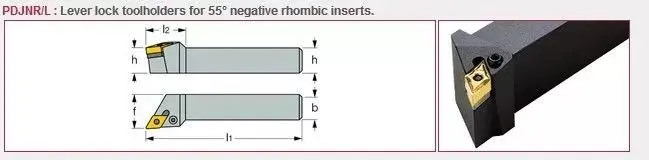

1.PDJNR

This kind of turning tool bar is suitable for fine turning of medium and large diameter workpieces. The modified tool bar can not only turn the outer diameter and end face, but also perform profiling and turning. It is widely used in fine turning. And the machining of shaft parts does not interfere with the center.

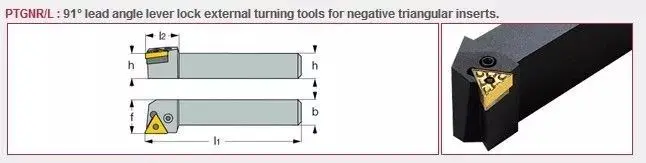

2.PTGNR

It is suitable for finishing turning of medium and large diameter. Note that this type of turning tool bar can only be turned to the outside diameter, which is not suitable for turning the outside diameter + end face.

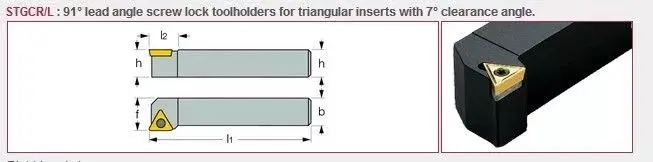

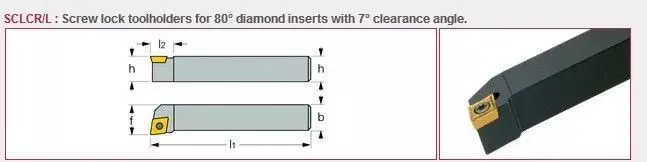

3. Stgcr and sclcr

It is suitable for fine turning of small and medium parts, but sclcr fine turning fine shaft and stgcr are not suitable for fine turning end face.

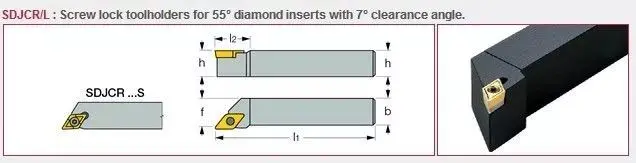

4.SDJCR

It is applicable to finish turning of all outer diameter parts, including profiling and shaft parts. No matter how big the diameter is, it is suitable. And the cutting is light and fast, and it is more anti collapse than VB / VC turning tool insert. This knife is in hand. It’s clean and precise!

Selection of turning tool bar for internal hole finishing machining

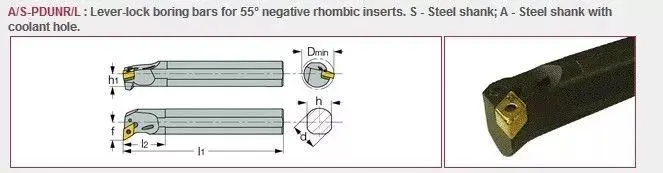

1.PDUNR

Similar to the outer diameter, the turning tool bar is suitable for finishing turning of medium and large diameter parts, and can also be used for profiling and end face processing.

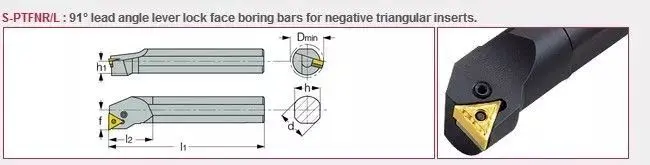

2.PTFNR

Suitable for fine turning of medium and large parts.

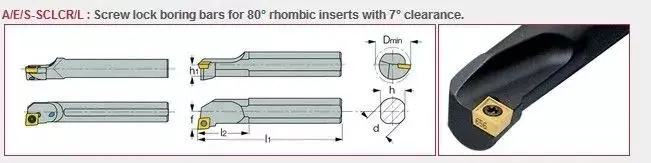

3.SCLCR

It is one of the commonly used turning tool bars for fine turning of internal holes, with a wide range of machining diameters, with a minimum of about 5.5-6.

4.STFPR

Small and medium aperture is one of the commonly used turning tool bars for fine turning. Generally, the machining aperture is not more than 20-25, and the minimum is about 8-10. The cutting speed is lighter than sclcr, and the number of cutting edges inserted by the turning tool is half more than CC. It has good economy.

5.SDUCR

Due to the restriction of the insert shape of the turning tool, the minimum machining diameter of this turning tool bar is about 14-16, so it is not as widely used as the previous two turning tool bars. However, because the tool tip angle is smaller than the previous two, the cutting is lighter and faster, and it can also be used for profiling.