?????? ??? ?? ??? ?????????? ??? ????? ???? ???? ??, ?????? ??? ?? ?????? ?? ??? ???? ?? ?? ?????? ????? ?? ????? ????? ?? ?????? ?? ?? ???? ?? ?? ????????? ??? ?? ????? ??? ?? ??? ?? ??? ????? ?????? ??? ????? ???? ???? ????? ??? ???? ?? ?? ????? ????? ???? ???

If you happen to be familiar with long overhang machining, probably you also have been haunted by an underlying problem that all single-point cutting tools with long shank can’t skirt around, which is vibration, or so-called chatter.

Main reasons that cause machining chatter

- Length of it exceeds 125mm,

- Its rotating rate per min is too high,

- Loose clamping of tool or workpiece.

Why is reducing chatter so vital to drilling process?

At present, in internal hole processing, ratio of length-to-diameter of a boring bar extension is generally less than 4:1. Once the ratio is more than that, the tool body will vibrate violently, resulting in poor tolerance of machined hole that can not meet requirements of product surface roughness.

Are there some other solutions to fix the problem?

Yes, basically veterans try the following 2 tips to alleviate chatter,

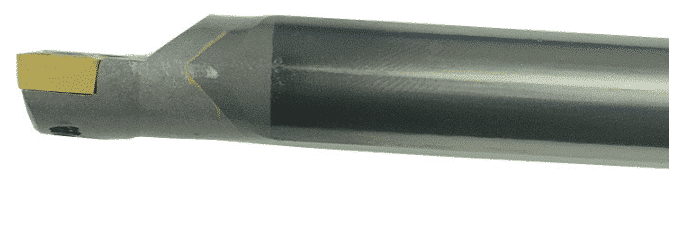

- Choose inserts with a smaller cutting edge angle. It will improve the whole tool’s performance of heat dissipation as well,

- Either lower feed rate or rotating rate of the spindle.

Nonetheless, you will find it still hardly improve the accuracy of machining due to limited cutting parameters. It inevitably moderates the metal removal rate per unit time.

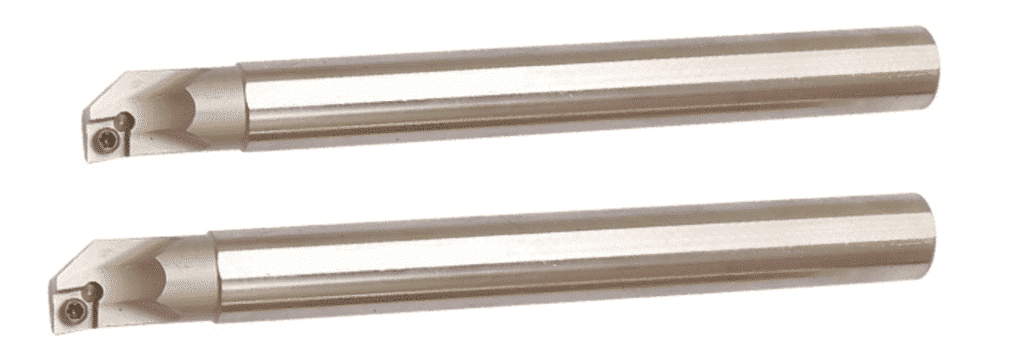

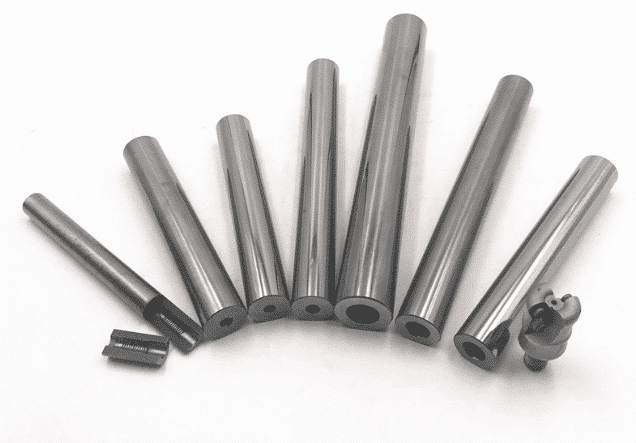

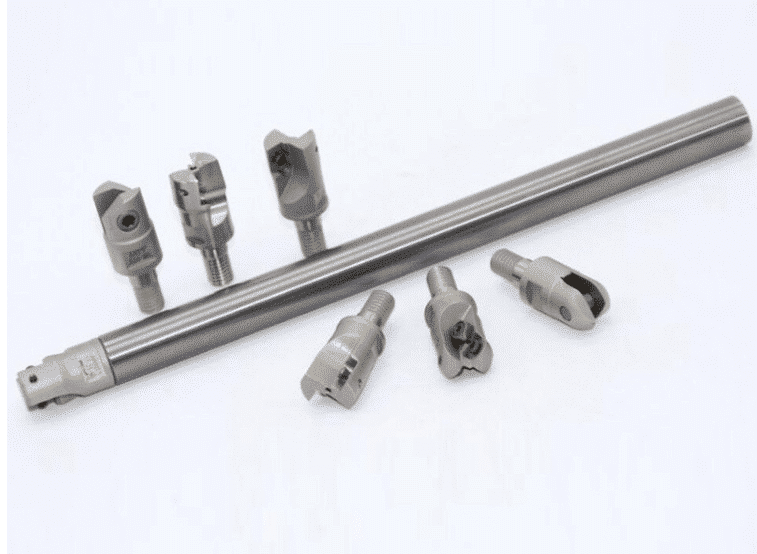

That’ s why we suggest you solve this problem from the ground up. For clients from the industry of tool fabrication, we recommend carbide boring tool holders (tool bit excluded) available in our stock. Boring bits assembled on it efficiently are allow to enhance its capability against disastrous processing result caused by vibration and cutting heat. Tool bit can be tightened by being screwed with threads carved in its shank’s internal hole.

How does it profit you if your boring bars are made of carbide?

It’s easily for low carbon steel to reach required rigidity of external turning tool and end face turning tool cause their overhang part out of spindle is generally not be too long. Whereas all boring bars have to be designed as slim as possible for readily protruding into machined hole in the long-reach application. They are way more vulnerable versus other types of lathe bars bearing chatter. Manufacturers have to develop suitable materials on that purpose, e.g. carbon steel, tungsten alloy, and carbide.

Under what circumstance should carbide boring bar be applied?

As we mentioned above, the length-to-depth ratio is a critical factor to affect what material to be used in the fabrication of a lathe boring bar. Steel carbon allows a 4:1 ratio, and tungsten alloy allows ratio of more than 4:1. Carbide is one of those optimal solutions for those boring bars in ratio up to 8:1 thanks to carbide’s high rigidity.

Why choose Mcct?

Please save your time sourcing manufacturer with design ability and full production line.

As an enterprise that has been in the business of carbide parts and produced them for 11 years. We are able to assure you that all parts are made in our wholly-owned factory operated under the instruction of ISO 9001. Sufficient expertise is obtained by us to tailor a series of carbide products for meeting requirements from our clients.

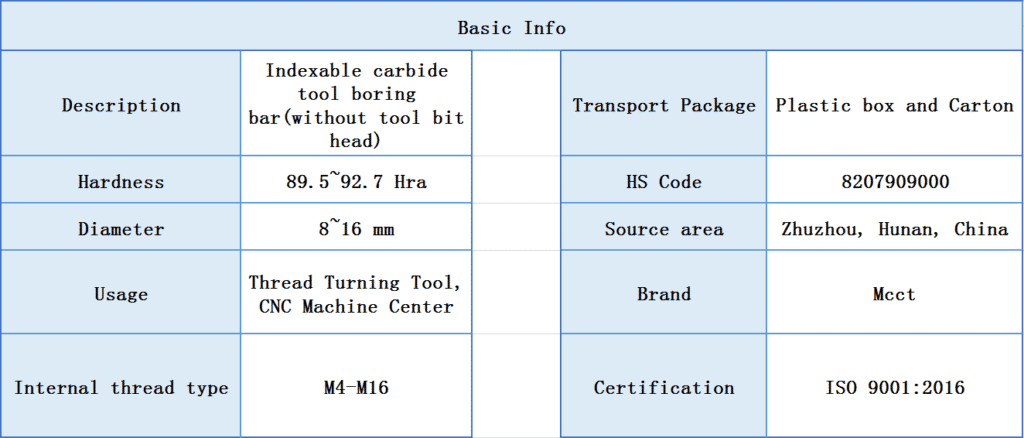

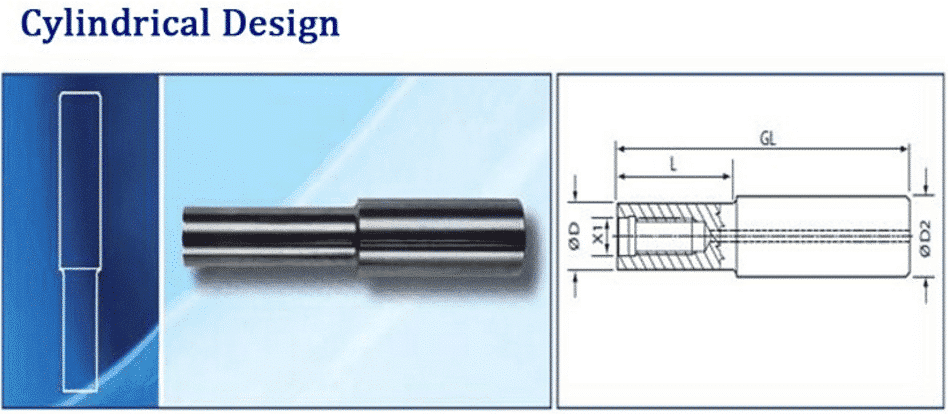

Product description

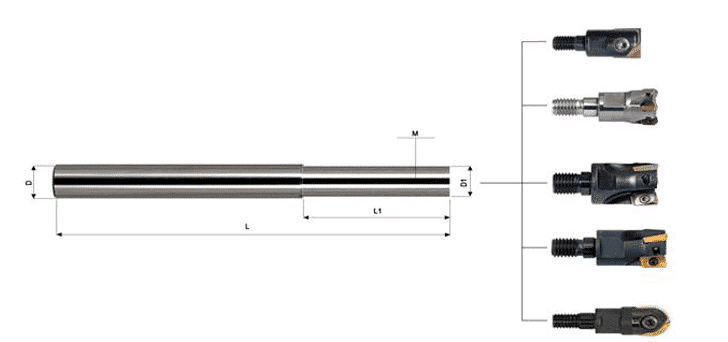

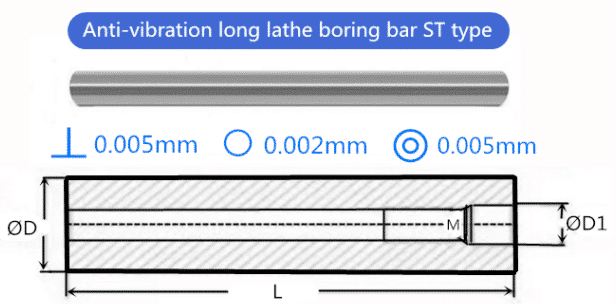

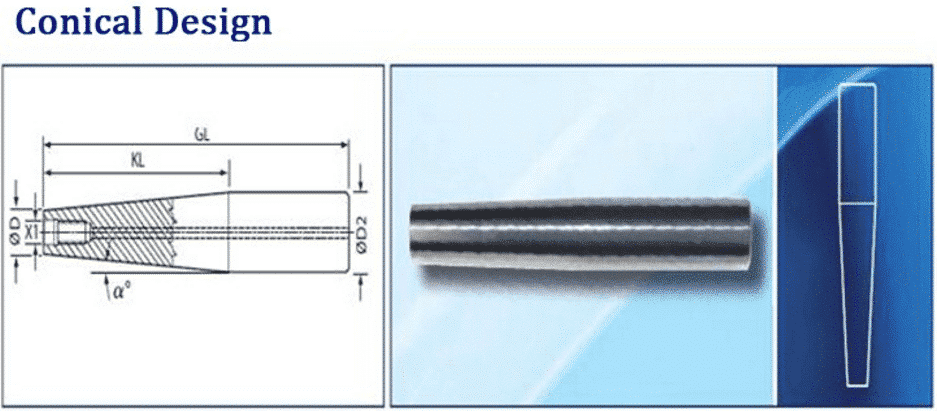

There are 3 types of boring bars you could find in our store. They are ST(standard), CL, and CN.

As shown in the following chart, we’ve made a list of common ST type boring bars. You could check out if there happens to be certain one of size that you need. Otherwise, please just contact our service personnel for all detailed info.

| ?? (????) | φ?? | φD1 | M |

| 100 | 8 | 4.5 | M4 |

| 80-150 | 10 | 5.5 | M5 |

| 100-200 | 12 | 6.5 | M6 |

| 100-200 | 15 | 8.5 | M8 |

| 100-200 | 15.6 | 8.5 | M8 |

| 100-250 | 16 | 8.5 | M8 |

| 150-250 | 19 | 10.5 | M10 |

| 100-250 | 20 | 10.5 | M10 |

| 150-300 | 24 | 12.5 | M12 |

| 150-300 | 25 | 12.7 | M12 |

| 200-400 | 32 | 17 | M16 |

Instruction of use

Please pay attention to the limitations of the depth-to-length ratio. Boring bar will get broken If the overhang part of shank scales out the limitation.

Reserve enough space for flushing the swarf, which means you should choose a boring bar with a suitable size according to the diameter and depth of the machined hole

If encounter problem about our products that you can’t figure out, please contact us directly or the agency where you purchase the item.

What’s more

We will launch solid boring toolbars and V-shaped welded boring bars in the near feature. Please subscribe to our blog you will be updated with more product details and tips of operating. We genuinely hope our insistence on the highest of standards of products we provide is able to convey the enticing values the tool manufacturer has to offer and impress you someday.