??????? ????????? ???? ???? ??, ?? ???? ???????? ?? ???????? ?? ???????? ???? ??? ?????, ??????? ???????? ?? ????? ?? ??? ???????, ??????? ??????? ?? ?????? ???? ??? ??? ??? ???? ????? ?? ???????? ?? ???? ???? ???????? / ???????? ?? ?????? ???:

Deburring, chamfering these small processes are often in the work can not be underestimated, today we summarize some of the information shared in the past, hoping to bring help to everyone’s work.

????????? ?????

????????; ?? ???????? ???? ????-???? ?????? ?????, ???? ??? ?? ???????? ??????? ?? ???? ?? ???????? ?????? ?? ??? ???? ???

????? ??????? ????

??????????????? ??????? ?? ???????? ?? ???? ??, ???? ?? ??????? ?? ??????? ???????? ?? ??????? ??? ?? ???? ?? ???? ??? ?? ?????? ??? ?? ??????, ??????????, ??????????? ??????, ???? ??? ???, ?????????, ???? ?? ???? ???????? ??? ??? ????, ????? ????, ????????? ???, ?????? ??? ????? ????, ??? ?? ??????? ???? ????? ?? ??????? ??? ????? ???? ?? ???? ??? ?? ?????? ????????? ?? ??? ??????? ?? ???? ??????? ??????? ??, ????? ????? ?? ??? ?? ?????? ?? ??????? ???? ?????

?????????????? ????

?????????????? ?????? ???? ?? ??????? ?? ????? ?? ??? ?? ??????????????? ??????? ????? ????? ????? (????? ?? ????) ?? ??????? ?? ????????? ???? ?????? ?? ???, ???? ??? ?? ??????? ?????? (????? ?? 0.3-1 ????) ?? ??? ??? ????? ????? ????? ?? ????????? ??? ?? ????????? ?? ?????? ?? ??? ??????? ???? ???? ??, ?? ???? ????? ?? ???????? ??? ?? ??? ??? ???? ???? ??, ???? ?????????????? ????????? ???? ?????? ?? ???????? ??? ??????? ?? ?????, ????? ?? ????? ???? ????? ?? ??????? ?? ????????? ????? ?? ????? ???? ??, ?? ??????? ???? ????? ?? ??????? ?? ????????? ????? ?? ????? ???? ??? ??????? ?? ????? ?? ??? 0.1-0.3 ????? ?? ???? ?? ??? ?? ?? ???? ????????????? (????? ?? ?????? ???????? ?? ?????? ??????? ???? ???) ???? ??? ?? ???? ????? ?? ??????? ????? ??? ??, ?? ????????? ???? ????? ??????? ????? ?? ??? ?? ?????, ???? ????????????? ?????? ??? ???? ?????? ????????????? ??? ?? ?? ???????? ??? ??????? ?? ???, ??????? ?? ??? ???? ????? ?? ???????? ?? ???? ???? ?????? ??????????????? ??????? ????? ??? ?? ???? ??? ??????? ??? ???? ????? ?? ??????? ???? ?? ??? ??????? ??? ???? ???? ??????? ?????? ?? ?? ????? ???? ??? ????? ?? ???? ?????? ????? ?? ?? ??? ???? ??? ?? ???? ?? ????? ????? ????, ???????, ????????? ???, ????? ???? ?? ??????????? ??? ?? ?????? ?? ???-??? ??? ????? ?? ??? ???? ?? ??? ???? ???? ??? ?????? ?? ?? ?? ??? ?? ??? ?? ????????? ?? ?????????????? ?? ???????? ???? ??, ??? ???? ??? ??? ?? ????, ?? ???? ?? ?? ????? ?????? ?? ?? ???????? ??????

???????????? ????

When the ultrasonic energy generated by ultrasound acts on the liquid in which the vibration is in a sparse state, it will tear into very small holes (that is, the internal is a vacuum). These holes will generate up to hundreds of atmospheric pressure instantaneous pressure when they break, which is called cavitation phenomenon. Ultrasonic deburring is to use the instantaneous impact force of hundreds of atmospheric pressure produced by “cavitation phenomenon” to remove the burrs attached to the parts. Ultrasonic deburring is not applicable to all burrs, mainly for some micro burrs. Generally, if the burrs need to be observed by a microscope, we can try to remove them by ultrasonic method. For the visible burr, it mainly depends on the bonding strength. The burr with weak bonding strength can be treated by ultrasonic. Generally, if the burr can only be treated by the cutter, the ultrasonic method is not available at all. Advantages and disadvantages of ultrasonic deburring.

???? ???? ?? ??? ????

???? ?? ??? ?? ?? ?????? ??, ?? ???? ?? ?????? ?? ??? ??? ???? ??, ?????????? ?? ??? ??????? ????????? ?? ????? ?? ????? ?? ??? ???? ????????? ?????? ?? ?? ????? ???? ??, ?? ??? ??, ?? ???? ?? ???????? ?? ??????? ?? ???? ??? ?? ????????? ?? ???, 30mpa-50mpa ?? ??????? ???? ???? ???? ??? ???? ????????? ??, ?? ??????? ?????? ??????? ???? ???? ?? ???? ??? ??? ???? ???? ???? ??, ?? ??????? ?? ????? ?? ???? ??, ????? ??????? ?? ?????? ???????? ?? ????? ??? ?? ??? ??, ?????????? ??? 20MPa ?? ???? ??? ???? ??? ???? ??? ?? ?? ????? ??? ???? ???, ?? ????????? ??? ???? ?? ???? 50MPa ???? ?? ????? ???? ?? ???? ??? ?? ????? ?? ??? ?? ???? ??? ????? ?? ??????? ???? ?? ??, ?? ?? ?? ???? ?? ???? ?? ?? ???? ??? ????? ??????? ?? ?????? ??? ???? ???? ???? ???? ?? ??????? ????? ?? ???? ?? ???? ???????? ???, ??????? ???? ?? ????????? ??? ??????? ???? ?? ???? ??: ??????? ?????? ???? ?? ???? ?????? ????? ??????? ?????? ???? ?? ???? ?? ???? ?? ?? ?? ?????? ????? ???? ?? ??????? ?? ???? ?? ??? ??????? ??? ???? ?????? ?? ?? ?? ???? ?? ????? ???? ?? ?????? ?? ?????? ????? ???? ??, ?? ????? ???? ??? ????? ??? ?? ???? ??? ??? ?? ??????? ?????? ????? ???? ??; ???? ???? ?????? ??????? ??? ?? ?????? ???????? ?? ?????? ?? ???? ?? ????? ???? ?? ??? ?? ???? ?? ???????? ?? ???? ?? ???? ????????? ??????? ???? ??, ??????? ??? ?? ????? ??? ?? ?????????, ???? ??? ??? ?? ????? ???? ??? ???? ??? ?? ?????? ???? ??, ????? ???? ??? ?? ????????? ?? ???? ???? ?? ?? ????? ?? ???? ???? ?? ????, ???? ??? ?? ??? ?? ??????? ?????? ?? ?????????? ???????? ??????? ?? ?? ????? ?? ???? ?? ???? ???

????? ??????? ????

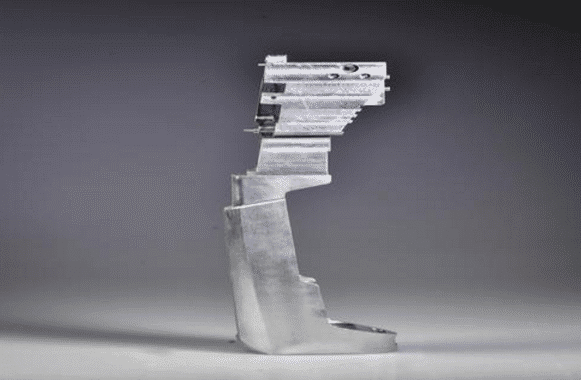

Also known as electric thermal deburring, thermal deburring is recognized as the most suitable advanced technology for large-scale deburring of small workpieces in the world’s machinery manufacturing industry. Only two domestic enterprises can produce this equipment. It uses hydrogen and oxygen to mix in the closed chamber which is used to treat the workpiece, ignites and burns instantly, and has a violent thermochemical reaction with the workpiece surface burr in a very short time, so as to achieve the purpose of burr removal. Thermal deburring is a special processing technology, which has the characteristics of high efficiency, high universality, good accessibility, even and thorough deburring, smooth workpiece surface, and not limited by workpiece material, shape and burr position. It is especially suitable for deburring of workpieces with complex cavity, intersecting hole system, deep hole, blind hole, threaded hole and other difficult deburring which cannot be solved by other process methods. It can be used for deburring of non-metallic materials such as black, non-ferrous metals and thermoplastics, and for deburring of metal die casting and plastic parts. Because of its high processing efficiency and low direct cost for production, it is especially suitable for large-scale continuous production environment. It is an ideal efficient processing equipment for large-scale industrial production.

???????? ???????? ????

The thickness of the flash (or burr) of rubber, plastic products, zinc magnesium aluminum alloy and other products is much thinner than that of the products, so the embrittlement speed of the flash (or burr) is faster than that of the products. In the period when the flash (or burr) is embrittlement and the products are not embrittlement, the frozen deburring (trimming) machine strikes the products by shooting projectiles, so as to remove the products in embrittlement The flash (or burr) of. The frozen deburring (trimming) machine is a kind of quick embrittlement of rubber, plastic products, zinc magnesium aluminum alloy flash by using the ultra-low temperature of liquid nitrogen. In this state, the frozen particles ejected at high speed impact the product’s burr (or Flash), so as to not only remove the product’s burr (or Flash) with high quality and efficiency, but also keep all of the product itself Special deburring (trimming) equipment with unchanged physical properties. It can greatly improve the trimming (deburring) accuracy of products and has a high degree of intensification. This kind of equipment has become an indispensable equipment for finishing and deburring of precision rubber and plastic products and die-casting enterprises.

??????? ?? ????

??????? ??????? ???? ????? ?? ????? ??????? ?????? ?????? ??????? ???? ?? ??? ???? ???????? ??????? ??????? ????? ?? ????? ???? ??, ???? ??????? ????? ??? (?????? ????? ???? ???? ??????) ?? ??????? ??? ?????? ??? ?? ?? ????? ?? ???? ??? ?? ???? ?? ???, ????? ???? ???? ?? ??? ?????, ??? ??? ?????, ???????? ?? ?????????? ?????, ??????? ????? ????? ?? ???????? ????? ????? ?? ??????? ?? ??????? ???? ?? ???? ????? ??? ?? ???? ????, ????? ??? ???, ?????? ?? ????? ???? ?? ???? ??????? ?? ???, ?? ???? ???? ?? ???? ?????? ???? ???? ??, ?? ?? ??????? ?? ??? ?? ?????? ???? ???????? ?? ?? ??????? ?? ?????? ?? ???????? ???? ??? ??? ?? ?????? ?? ?? ?? ???, ?? ?? ??? ??? ????? ?? ??? ???? ???? ?? ???? ?? ??????? ???? ????, ?????, ?????, ???????????, ?????, ??????????, ????, ???????? ????? ?? ???? ????????? ???? ???-???? ????? ?? ?????, ?????? ?? ????? ?? ??? ??????? ???

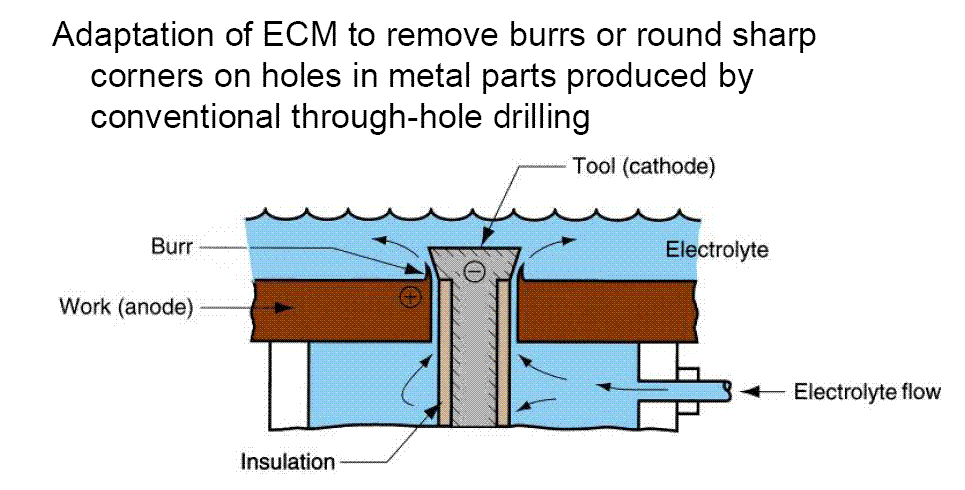

???????? ????

?? ?? ??????? ???????? ?? ??????? ?????? ????? ??, ?? ?????? ?? ???? ??????, ??????????????????? ?? ????????, ???????? ???????? ?? ??????, ????? ?? ????? ??????????, ??????? ??????????? ?? ???? ?????? ?? ?????? ??? ???????? ?? ?????? ??? ?? ????? ???? ??? ???????????? ?? ????? ?? ???? ?? ??? ????????? ??? ??????? ?????????? ??? ????? ?? ???, ??????? ?????????? ????? ???? ?? ?????? ??? ??, ?? ??????? ?????? ?? ???????? ?????????? ??????? ??????? ?????????? ?? ???????????? ? ???? ?? ?????????? ???????? ?? ?? ???? ??, ??????? ????? ??????? ?????? ?? ???? ??????? ??, ????? ???????? ??????? ?? ????????? ?? ?? ?????? ???? ???

???????? ?????????? ?? ??????? ??? ???: ??????????? ??, ???????????? ???????? ???????, ????????????? ???????, ????????????? ???? ??, ??????? ???, ??????? ?????, ????? ????, ????? ???, ?????? ?????, ???? ???? ????

???????? ???????? ?? ??? ????

????? ???? 150 ?????? ???????? ?? ???????? ?????? ?? ????? ?? ???? ??? ?? ????? ?? ???? ?? ??? ???? ??? ???? ?????, ??????? ???? ??? ???? ?? ????? ???????? ???? ??, ?? ????? ?? ???????? ???? ????? ?? ??????? ?? ????????? ?? ??? ?? ???? ??, ????? ??? ?? ???? ??????? ?? ??????? ?? ?????? ?? ????

??? ?????: ????, ?????? ?? ????? ?? ?????? ????????? ?? ???? ?????????? ?? ????????? ??? ?????? ??? ?? ????????? ?? ???? ????? ????? ?? ???? ??, ???? ????????? ?? ???? ???? ????? ?? ?? ??????? ?? ?? ?? ????? ??? ?? ????