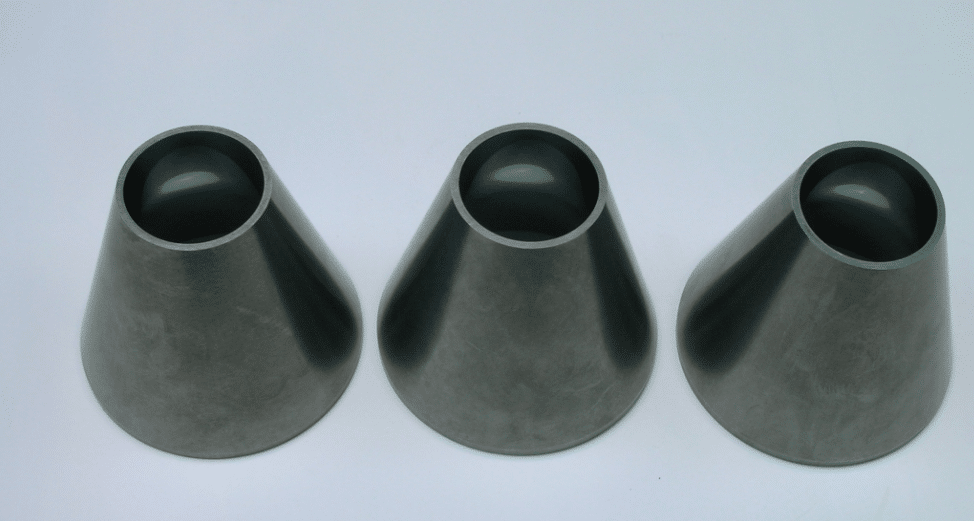

Cemented carbide nozzle is made of precision machinery and cemented carbide material (superhard alloy). The bending resistance is 2300n / mm and the hardness is hra90 degree. When machining cemented carbide nozzle, we achieve precision grinding and surface treatment to achieve the hole roughness of ra0.1 and the roughness of both ends of R is Ra0.025. There is a scientific radius of curvature design at the two entrances. This design ensures the smooth passage of the thread. Due to the whole material processing, there is no elevation angle on the drilling hole, and the bending and blocking phenomenon has been improved compared with ruby nozzle. Cemented carbide nozzle is made by hot pressing and sintering hot straight hole and hill hole. Because of its hardness, low density, excellent wear resistance and corrosion resistance, cemented carbide nozzle has been widely used in sand blasting and shot peening equipment, which ensures that the product can be used in the best air and abrasive for a long?time.

advantages

Advantages of cemented carbide nozzle: corrosion resistance, long service life, excellent performance, high cost performance, not easy to wear.

Carbide nozzle and other nozzles: common nozzle materials include cast iron, ceramics, tungsten carbide, silicon carbide, boron carbide. Ceramic nozzles are only used in non aggressive light equipment and abrasive in explosion cabinets. Tungsten, silicon, and boron carbide are the most popular blasting applications due to their long service life. The following is a list of cemented carbide nozzles and their comparison with other nozzles.

Approximate service life per hour

Nozzle material: steel shot / sand sand / alumina

Carbide nozzle 500-800 300-400 20-40

Alumina nozzle 20-40 10-30 1-4

SiC nozzle 500-800 300-400 50-100

Boron carbide nozzle 1500-2500 750-1500 200-1000

types

The shape of nozzle hole of cemented carbide determines its air flow pattern. The nozzle generally has a straight hole or a limiting hole, a hill hole.

1. Straight hole (cemented carbide nozzle 1): the straight hole nozzle forms a sealed air flow mode for on-site or internal air flow. This facilitates the realization of small tasks, such as cleaning parts, weld forming, cleaning handrails, steps, plaques, or stone carvings and other materials.

2. Traditional long hill design (carbide nozzle 2)

3. The orifice nozzle forms a sufficient airflow pattern, and the grinding speed can be increased up to 100% for a given pressure. The best choice of Venturi surface is to improve the productivity of the nozzle. Compared with the straight hole nozzle, the productivity of the long mound nozzle can be increased by 40% when the abrasive consumption is about 40%.

4. Double venturi (carbide nozzle 4): Double venturi and wide throat nozzle are the enhanced version of long venturi nozzle. The double dome style can be thought of as having two nozzles between a set of slits and holes to allow the incoming atmosphere to enter the downstream section. The outlet end is also wider than the traditional nozzle. These two modifications are made to increase the size of the airflow pattern and minimize abrasive loss at a speed.

5. Wide throat nozzle (carbide nozzle 5): wide throat nozzle is equipped with a large outlet and a large divergent outlet. When matched with the same size hose, they can increase productivity by 15% over a smaller throat nozzle. When wide throat nozzles also have large divergent holes, they can use a lower abrasive mode under higher pressure, and the yield can be as high as 60%.

For some lattice bridges, the back of the flange, the inside of the pipe type of shrink point, can effectively use angled nozzles. Many operators spend a lot of time and abrasive to wait for a bounce to complete the job. The use of angle nozzle as long as hair less time is always able to repair quickly, reducing the overall time.

Solicitud

Cemented carbide has a series of excellent properties, such as high hardness, wear resistance, good strength and toughness, heat resistance and corrosion resistance. Especially, its high hardness and wear resistance remain unchanged even at 500 ℃ and high hardness at 1000 ℃. Cemented carbide is widely used as tool material, such as turning tool, milling cutter, planer, drill bit, boring tool, etc. it is used to cut cast iron, non-ferrous metal, plastic, chemical fiber, graphite, glass, stone and ordinary steel, as well as refractory materials such as heat-resistant steel, stainless steel, high manganese steel and tool steel.

Cemented carbide nozzles offer the advantages of economy and longer service life when it is unavoidable to rough load and unload and media used to cut abrasives (glass beads, steel balls, steel sand, minerals or cinders). Traditionally, cemented carbide is the preferred material for cemented carbide nozzle.

Cemented carbide nozzle is widely used in surface treatment, sandblasting, spray painting, electronic, chemical process and other industries.

Cemented carbide nozzles are also used in different applications, such as for wire straightening, wire guides and other aspects.