??

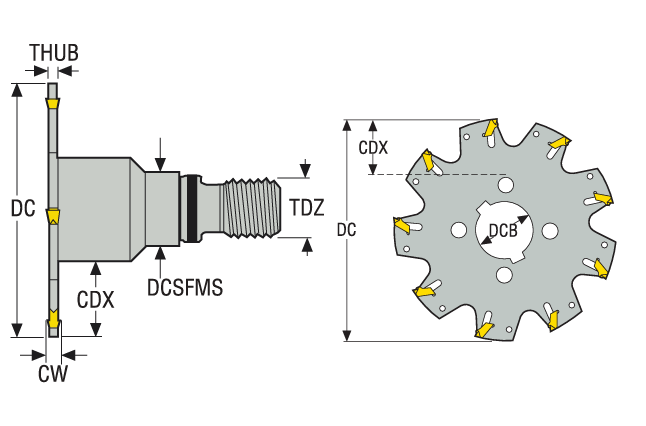

Structure of a Three-Sided Edge Mill Cutter

A three-sided edge mill has a circular shape, with cutting edges evenly distributed around the outer circumference in a serrated pattern, and a center bore for the installation of the cutter.

The main cutting edge of a three-sided edge mill is distributed on the cylindrical surface of the cutter, while the secondary cutting edges are distributed on the end faces of both ends. All three cutting edges have a relief angle, hence the name “three-sided edge mill cutter.”

Three-Sided Edge Mill Cutter Types

Classification by Tooth Shape: Three-sided edge mill? can be classified into two types by tooth shape: straight teeth and staggered teeth.

Straight Tooth Three-Sided Edge Mill Cutter

Characteristics: The blades are arranged in a straight line.

Applications: Straight teeth are used for milling shallow fixed-size grooves and can also mill general slots, step faces, and side finishing processes.

Staggered Tooth Three-Sided Edge Mill Cutter

Characteristics: The blades are distributed in an interleaved pattern, which helps to achieve smooth feed and reduce vibration.

Applications: Suitable for milling deeper slots or occasions that require a higher surface finish.

Classification by Structure: Three-sided edge mills can be classified into solid three-sided edge mill cutters, carbide three-sided edge mill cutters, and indexable three-sided edge mills.

Solid Three-Sided Edge Mill Cutter

Characteristics: The surface is treated with a special coating to improve tool life and cutting performance.

Applications: Enhanced heat resistance and wear resistance, suitable for high-speed cutting and difficult-to-machine materials.

Carbide Three-Sided Edge Mill Cutter

Characteristics: The blades are made of carbide welding, offering higher hardness and wear resistance.

Applications: Suitable for machining materials with higher hardness, such as cast iron and steel.

Indexable Three-Sided Edge Mill Cutter

Characteristics: Uses replaceable blades, which is convenient for maintenance and cost control.

Applications: Widely used for rough and semi-finish machining of various materials.

?

Applications of Three-Sided Edge Mill Cutters

Three-sided edge mills are widely used in mechanical machining. The common usage is to mount them on the arbor of a horizontal milling machine for machining, or they can also be installed on other vertical machines (such as machining centers, vertical milling machines, etc.) for machining grooves, steps, and side faces.

Plane (Side) and Step Milling?

Depending on the product structure, three-sided edge mill cutters with different diameters and custom tool holders can be selected to machine multiple faces in one operation.

This combined machining method, due to the simultaneous machining of multiple faces, results in greater cutting forces. Therefore, it is necessary to carefully select the diameter and length (overhang) of the tool holder to ensure its strength. Additionally, it is important to set the cutting parameters reasonably and ensure the stable clamping of the fixture and workpiece. Otherwise, it may lead to tool damage or product scrap.

Slot milling

Used for machining slots of various widths and depths.

Other special machining

such as T-slot, circular arc slot, etc.

The above are the structural features and applications of the three-fluted end mill. When using it, the appropriate type of cutting tool should be selected based on factors such as the size of the product to be machined and the hardness of the material.