Sources of Waste tungsten carbides

Globally, approximately 30,000 to 50,000 metric tons of waste tungsten carbides are generated annually, with China accounting for over 40% of this volume, indicating tremendous recycling potential. Specifically, waste tungsten carbides primarily originate from the following sources:

Residual materials from worn cutting tools, such as lathe tools, milling cutters, and drill bits;

Large tungsten carbide components, including mining drill bits, molds, and rolling mill rolls;

Certain wear-resistant electronic components (e.g., semiconductor packaging materials) that contain tungsten carbides.

Recycling Methods for Waste tungsten carbides

Currently, mainstream recycling technologies include mechanical, chemical, and zinc melting processes, each with its own advantages and limitations:

Crushing Method

The mechanical crushing method is one of the simplest approaches for recycling waste tungsten carbides. It does not alter the chemical composition of the waste material and does not require separation of tungsten and cobalt. After surface cleaning, the waste tungsten carbide undergoes mechanical crushing and ball milling to produce a mixed powder with a chemical composition nearly identical to the original waste (except for a slight increase in iron content and decrease in carbon content).

For tungsten carbides with low cobalt content (which tend to have relatively lower strength), the material can be manually or mechanically crushed to a certain fineness before being ground in a wet mill to achieve the desired particle size for reuse in tungsten carbide production.

Advantages:

Simple process, short workflow

Low energy consumption

Environmentally friendly (no chemical pollution)

Limitations:

Risk of contamination from metal tool debris during manual crushing

Ineffective for high-cobalt tungsten carbides due to their resistance to crushing

Difficulty in ensuring consistent quality for recycled products made from complex carbide mixtures

Advancements in the Crushing Method

Russian researchers have developed an innovative tungsten carbide?recycling process utilizing a simple mechanical crushing approach. This method employs a novel high-power crusher—the conical inertial crusher—enabling high-quality recovery of waste tungsten carbides through crushing and fine grinding alone, without requiring any chemical treatment.

For instance, when processing waste YG6 anvils (used in synthetic diamond production), the waste anvils are first crushed in the conical inertial crusher to produce raw material for tungsten carbide?manufacturing. To enhance the performance of the crushed powder mixture, it is recommended to add 1%–2% cobalt powder, which improves compaction and sintering densification.

Currently, the crushing method continues to evolve, with the adoption of more advanced, cleaner, and efficient crushing equipment for processing waste tungsten carbides.

Zinc Melting Process for tungsten carbide?Treatment

Fundamental Principles of the Zinc Melting Process

The mechanism of the zinc melting process for tungsten carbides is based on the formation of?low-melting-point carbides?between zinc and the binder-phase metals (cobalt or nickel) in tungsten carbides at?900°C. At?896°C, the solubility of cobalt in zinc reaches?27%, allowing the binder metal to separate from the tungsten carbide?and form a?zinc-cobalt solid-solution carbide?liquid. This disrupts the tungsten carbide’s structure, leaving behind a loosely bound?hard-phase skeleton.

Since zinc does not chemically react with refractory metal carbides, and given that zinc’s vapor pressure is significantly higher than cobalt’s at specific temperatures, zinc can be?evaporated and recovered (at 925°C)?for reuse. As a result, the carbide powder obtained through the zinc melting process retains most of its original properties. After the process, cobalt or nickel is extracted into the zinc melt, while the carbides remain. The zinc is then distilled off and recycled for subsequent reuse.

Traditional zinc melting furnaces?are?vertical vacuum furnaces. The system operates under conditions ranging from?vacuum to partial-pressure atmospheres, up to just below atmospheric pressure. The components of zinc melting equipment are illustrated in?Figure 2, while the furnace’s main structure is shown in?Figure 3.

Key Characteristics of the Zinc Melting Process

The zinc melting process was invented by the British in the 1950s. Subsequently, the United States improved this process and enhanced the equipment. After the 1970s, it became widely adopted in many countries. In China, many manufacturers engaged in recycling waste tungsten carbides have mastered this method. Its main advantages are simple process, short flow, simple equipment, small investment, and low cost, making it particularly suitable for processing waste tungsten carbides with cobalt content below 10% and applicable for small enterprises to reuse waste tungsten carbides for carbide reproduction.

However, this process also has some disadvantages. First, the residual zinc content in the mixed material is relatively high. During the zinc melting and zinc recovery processes, whether the equipment is reasonable or not affects the zinc recovery efficiency. Second, the entire process consumes a large amount of electricity, with power consumption for each ton of tungsten carbide reaching approximately 6,000~12,000 kW·h. Additionally, there are environmental protection issues, as zinc emissions may have certain impacts on operators.

Currently, China’s WC-Co carbides have three tungsten carbide grain structures: coarse, medium, and fine. P-type carbides can be roughly divided into three categories based on titanium content: low-titanium, medium-titanium, and high-titanium. During recycling, it is best to strictly separate them to avoid mixing different sizes of tungsten carbide grains or zinc-melted mixed materials with different titanium contents.

Electrochemical Methods

Electrochemical methods mainly include the electrolysis method, as well as the electrolytic electrodeposition method and the electrodialysis electrolysis method developed from the electrolysis method.

Each method offers unique capabilities for metal recovery and purification from tungsten carbide waste streams.

Principle of Electrolysis Method

The electrolysis method involves directly placing waste tungsten carbides into an electrolytic cell with acids (hydrochloric acid, sulfuric acid, nitric acid, etc.) as the electrolyte. During electrolysis, the Co in the carbide transforms into Co2? and enters the solution, while the WC, having lost its binder metal cobalt, becomes a porous carbide. The cobalt-containing solution is precipitated with ammonium oxalate, and cobalt powder is obtained after calcination and reduction. The WC can be directly used in tungsten carbide production after ball milling and crushing or appropriate treatment (such as post-crushing carbon supplementation and re-carburization).

The electrolytic electrodeposition method takes advantage of the fact that hydrogen’s deposition potential is more positive than that of cobalt, causing hydrogen gas to preferentially deposit at the cathode. As the Co2? concentration increases and H? decreases, metallic cobalt is simultaneously deposited alongside hydrogen at the cathode. Thus, the electrolytic system becomes an electrolytic refining process where waste carbide serves as the anode, CoCl? as the electrolyte, and pure cobalt is deposited at the cathode.

The electrodialysis electrolysis method introduces a cation-exchange membrane into the electrolytic cell, dividing it into anode and cathode compartments. The cation-exchange membrane, a functional polymer film selectively permeable to ions, allows only cations to pass while blocking anions. Consequently, Co2? migrates through the membrane into the cathode compartment during electrolysis, while OH? accumulates in the cathode compartment due to the membrane’s barrier effect, raising the pH and resulting in Co(OH)? precipitation. Compared to conventional electrolysis, both the electrolytic electrodeposition and electrodialysis electrolysis methods shorten the cobalt recovery process and improve recovery rates.

High-Temperature Treatment Method

Principle of High-Temperature Treatment

The high-temperature treatment process is a novel recycling technology for tungsten carbides. This method involves re-sintering tungsten carbides at high temperatures to loosen their structure and promote grain growth. Subsequent mechanical crushing yields high-quality powder suitable for producing coarse-grained tungsten carbides. tungsten carbides manufactured from this powder exhibit performance metrics that meet or exceed those of standard carbide products. The high-temperature treatment process provides a new approach for recycling waste tungsten carbides and producing coarse-grained tungsten carbides.

High-Temperature Treatment Process for Waste tungsten carbides

The high-temperature treatment of tungsten carbides is conducted in specially designed high-temperature furnaces. Under a protective atmosphere at temperatures exceeding 1800°C, the waste carbide undergoes treatment where binder metals like cobalt liquefy and boil, causing carbide deformation and significant volume expansion. The carbide structure transforms into a porous, honeycomb-like formation, making the hardened carbide extremely easy to crush and process. During this high-temperature treatment:

A substantial liquid phase forms in the carbide

Atomic diffusion intensifies→

WC dissolution-precipitation effects strengthen→

WC grains grow rapidly from 1-2μm to several dozen or even hundreds of micrometers→

Defects in WC crystal structures are eliminated during recrystallization→

WC crystal structures become more complete→

Trace metal/non-metal impurities and harmful contaminants are removed

Characteristics of High-Temperature Method and Regenerated carbide Performance

This regenerated mixed material is particularly suitable for producing coarse-grained, high-cobalt-content tungsten carbides. For fine-grained, low-cobalt carbides:

- Higher treatment temperatures are required to generate sufficient stress for expansion and porosity

- Modified preparation and sintering processes are necessary for medium-fine grain production

Processing steps:

Initial crushing of treated carburo

Ball milling to -180 mesh (80μm) for regeneration suitability

The recycled carbide powder is ideal for coarse-grained tungsten carbide production. Test results show:

- Physical-mechanical properties match those of virgin powder carbides

- Grain size increases by 1μm

- Service life of rock drilling buttons and cold heading dies improves by 20%

Advantages:

- Short process flow

- Simple equipment requirements

- Clean recycled mixed materials

- Low environmental pollution

- High recovery rates

Limitations:

- High energy consumption

- Some cobalt loss during high-temperature processing

- Recycled material only suitable for coarse carbide grain carbides

Currently used by manufacturers in industrialized nations like Japan and Sweden.

Conclusión

Waste tungsten carbide recycling represents not just economic resource reuse but a crucial component of green manufacturing. With advancing technology and policy support, the recycling industry will become more efficient and environmentally friendly, contributing to global sustainable development.

What’s more, industrial enterprises should establish classified recycling systems.Individual users should properly dispose of used tools/drill bits through professional recyclers

“Waste is just resources in the wrong place” – tungsten carbide recycling perfectly embodies this philosophy!

]]>

Phase Composition of WC-Co Cemented Carbides

Figure 1 shows the vertical section of the W-Co-C ternary phase diagram along the Co-WC line. Taking a WC-60%Co alloy as an example:

Before liquid phase formation, the solubility of WC in Co increases with temperature.

At the eutectic temperature (~1340°C), a liquid phase with eutectic composition begins to form in the sintered body.

During sintering at 1400°C and subsequent holding, the sintered body consists of a liquid phase and residual WC solid phase.

Upon cooling, WC first precipitates from the liquid phase. Below the eutectic temperature, the WC-based carbides forms a two-phase structure of WC + γ.

Figure 1: Vertical Section of the W-Co-C Ternary Phase Diagram Along the Co-WC Line

In actual production, the composition of sintered bodies often deviates from the vertical section of the Co-WC line. Consequently, the alloy is not simply composed of γ+WC two phases. As shown in Figure 2 , the carbon-rich side of the γ+WC two-phase region borders the γ+WC+C three-phase region and the γ+C two-phase region, while the carbon-deficient side borders the γ+WC+η three-phase region. Only when the carbon content of the sintered body varies strictly within the γ+WC two-phase region can the WC-based carbide avoid the formation of a third phase. Otherwise, it may lead to carbon inclusions or the formation of carbon-deficient η phase.

Since the strength of the alloy is closely related to the structure and composition of the γ phase, while the presence of η phase may degrade toughness, extensive research has been conducted on the γ and η phases, as well as phase transformation processes, in an effort to control the phase composition of WC-Co alloys and improve their overall performance.

γ Phase Composition and Phase Transformation in WC-based carbides

As shown in Figure 2, the composition of the γ phase depends on the carbon content of the alloy, while its tungsten content increases with decreasing carbon content. When the alloy’s carbon content lies at the boundary between the γ+WC two-phase region and the γ+WC+η three-phase region, the γ phase exhibits the highest tungsten concentration. Conversely, when free carbon is present and the carbon content aligns precisely with the Co-WC cross-section (i.e., the theoretical carbon content of 6–12 wt.%), the γ phase contains the lowest tungsten concentration.

The tungsten concentration in the γ phase is also influenced by the cooling rate: slower cooling results in lower tungsten content, while rapid cooling leads to higher tungsten retention. This occurs because faster cooling suppresses the diffusion-driven precipitation of tungsten from the γ phase, locking in a non-equilibrium concentration. Additionally, higher sintering temperatures increase the tungsten solubility in the liquid phase, thereby raising the tungsten content in the γ phase at a given cooling rate. However, under sufficiently slow cooling, thermodynamic equilibrium dictates that the γ phase composition becomes independent of the sintering temperature.

In WC-Co cemented carbides, the γ phase is a cobalt-based solid solution of W and C. It exists either as discrete γ grains separated by grain boundaries or as isolated γ domains unevenly distributed within the matrix. Both γ grains and domains typically exhibit equiaxed or near-equiaxed morphologies. Notably, the volume fraction of γ domains increases with higher cobalt content in the WC-based carbide.

Factors Influencing γ Phase Transformation in WC-based carbides

Effect of Internal Stresses

The mismatch in thermal expansion coefficients between WC phase (384×10??/°C) and γ phase (1.25×10??/°C) generates microstructural stresses during cooling (tensile in γ phase, compressive in WC phase).

Increased cooling rate or quenching suppresses W diffusion precipitation in γ phase, elevating W concentration in room-temperature γ phase while reducing hcp γ phase content.

Cryogenic treatment (below Ms point) induces W supersaturation in γ phase, enlarging the free energy difference between fcc and hcp γ phases. Concurrently, enhanced internal stresses promote Ms transformation, markedly increasing hcp γ phase fraction—particularly pronounced in low-Co alloys.

Impact of Cobalt Content

In low-Co alloys (e.g., WC-8Co), thin γ phase layers (<0.3 μm) facilitate W diffusion to WC grains, lowering W concentration in γ phase. This raises the Ms point, favoring hcp γ phase formation during cooling and yielding higher room-temperature hcp γ phase content.

η Phase in WC-based carbides

Formation Mechanism and Morphology of η Phase

Due to the narrow carbon content range in the WC-γ two-phase region (Fig. 2), carbon deficiency in raw materials or sintering decarburization often leads to η phase formation (e.g., M?C-type Co?W?C, Co?W?C, and M??C-type Co?W?C). Among these, Co?W?C is most common.

Formation process

Heterogeneous nucleation: γ phase nucleates along WC-γ interfaces using WC grain surfaces as nucleation sites, facilitated by slow W diffusion from WC to γ phase and high W concentration at phase boundaries. γ phase tends to fill surface defects (high-energy sites) of WC grains.

Carbon loss and η phase precipitation

Rapid C diffusion in γ phase causes C depletion when WC dissolves, resulting in W/C ratio imbalance (room temperature [W]/[C]≈284).

During sintering (1350-1500°C), excessive C loss leads to W-rich γ phase, precipitating carbon-deficient η phase (intermediate phases like Co?W and Co?W?C form first, transforming to η phase at high temperatures).

Phase equilibrium and morphology

η phase growth consumes W and C, driving WC dissolution until equilibrium is reached.

η phase morphology is influenced by γ liquid phase flow (e.g., cross-shaped single crystals).

Key point: Carbon imbalance is the primary cause of η phase formation, with γ phase nucleation dependent on WC interfaces and high-temperature C loss driving η phase precipitation.

Factors Influencing η Phase Formation

Carbon content is critically important for η phase formation. In the WC+γ+η three-phase region:

Higher carbon content maintains W and C concentrations in γ phase closer to equilibrium, hindering η phase nucleation.

Mild carbon deficiency: η phase growth relies on dissolution of WC microcrystals in γ interlayers, resulting in η phases enveloping undissolved WC grains with regular geometries.

Severe carbon deficiency: Significant deviation from equilibrium W/C ratio in γ phase promotes extensive WC dissolution, leading to dispersed particulate η phase distribution.

Cobalt content effects

High-Co alloys contain more γ phase with better fluidity, facilitating W and C diffusion. While η phase nucleation is difficult, growth is easier, forming coarse, clustered grains.

WC grain size effects

Coarser WC grains promote η phase nucleation but slow growth, resulting in dispersed particulate phases.

Sintering process effects

Faster cooling reduces dwell time at η phase critical temperature, suppressing η phase formation.

Higher sintering temperatures increase γ liquid phase quantity, favoring coarse η phase grains, but excessive temperatures may keep γ liquid away from η phase boundaries, inhibiting η phase growth.

Conclusions

A comprehensive understanding of the phase transformation processes during the sintering of WC-based carbides is crucial for optimizing production processes, controlling phase composition and microstructure in the alloys, thereby creating favorable conditions for manufacturing high-performance WC cemented carbides.

]]>

The primary functions of binders in cemented carbide manufacturing

In the powder metallurgy of cemented carbides, binders (also called forming agents) play critical roles, including:

Improving Powder Flowability

Reduces interparticle friction, enabling homogeneous mold filling and uniform compaction.

Prevents powder segregation (e.g., separation of WC and Co).

Enhancing Green Strength

Provides sufficient “green strength” to prevent cracking or edge chipping during handling or demolding.

Minimizes elastic aftereffects (post-compaction expansion).

Lubricating the Mold

Reduces friction between powder and die walls, lowering compaction pressure and extending mold life.

Improves surface finish and minimizes defects (e.g., delamination, cracks).

Facilitating Debinding

Must be fully removable (via thermal decomposition or dissolution) before sintering to avoid carbon residue or impurities that degrade alloy properties.

Performance Requirements for Binders

The binder must possess the following characteristics:

Excellent Compatibility

Uniformly mixes with WC-Co powders without agglomeration or sedimentation.

Chemically inert to powders (e.g., no oxidation of cobalt).

Suitable Melting Point and Viscosity

Melting point must align with compaction temperatures (typically room temperature to 100°C) to ensure:

Liquid-phase homogeneity during mixing.

Solid-phase strength during pressing.

Too high moderate viscosity leads to impedes powder flow.

Too low moderate viscosity leads to insufficient binding force.

High Binding Capacity and Lubricity

Binding capacity: Ensures green strength (flexural strength typically ≥5 MPa).

Lubricity: Reduces compaction pressure (e.g., from 600 MPa to 400 MPa).

Controlled Debinding Behavior

Broad debinding temperature range (e.g., 150–500°C) to prevent cracking from rapid volatilization.

Low carbon residue after debinding (<0.1%) to avoid disrupting alloy carbon balance.

Environmental and Safety Compliance

Non-toxic, low volatility (e.g., water-soluble PEG outperforms solvent-based rubber binders).

Meets industrial emission standards (e.g., sulfur- and chlorine-free).

Cost-Effectiveness

Low-cost and readily available (e.g., paraffin wax is more economical than rubber).

Recyclable or easy to dispose of (e.g., PEG can be water-washed and recovered).

Types of Binder

When manufacturing cemented carbide products, selecting the right binder is crucial for quality and efficiency. Here’s a detailed comparison of the three most common binder types to help you make the best choice for your application.

Paraffin Wax

Characteristics:Composition: Hydrocarbon-based, solid at room temperature with low melting point (50-70°C)

Best for: Small, simple-shaped carbide products

Advantages:

Excellent lubricity reduces die friction

Low debinding temperature (200-400°C) simplifies processing

Cost-effective and readily available

Limitations:

Lower green strength (prone to cracking)

Potential carbon residue during high-temperature debinding

Temperature-sensitive – requires dry storage

Pro Tip: Ideal for mass production of standard inserts where cost is key.

PEG (Polyethylene Glycol)

Characteristics:Composition: Water-soluble polymer with adjustable molecular weight (PEG-2000/4000)

Best for: Complex-shaped tools and precision molds

Advantages:

Higher green strength for intricate shapes

Water-soluble – enables aqueous pre-debinding

Minimal carbon residue

Limitations:

Hygroscopic – requires humidity control

Narrow debinding window (200-300°C)

More expensive than paraffin

Pro Tip: The go-to choice for premium cutting tools requiring precision.

Rubber (SBR, etc.)

Characteristics:Composition: Polymer elastomer requiring organic solvents (e.g., acetone)

Best for: Large, high-density components like rolls and mining tools

Advantages:

Highest green strength

Excellent elasticity prevents cracking

Limitations:

Challenging debinding (500°C+)

Potential sulfur contamination

Environmental concerns with solvents

Highest cost

Pro Tip: Reserved for specialized applications where extreme strength is critical.

Compatibility Principles Between Binders and Wet Milling Media

Paraffin Wax

- Requires organic solvents (e.g., ethanol, acetone)

- Limited solubility in ethanol alone – heating often needed

Recommended Medium: Ethanol + 10-20% acetone (enhances solubility)

PEG (Polyethylene Glycol)

- Excellent water solubility

- Requires oxidation protection for cobalt

Recommended Medium: Deionized water + 0.5% antioxidant (e.g., oxalic acid)

Rubber Binders

- Only soluble in strong organic solvents

Recommended Medium: Pure acetone (requires sealed system to prevent evaporation)

Performance Comparison of Three Major Binder Systems

Binding Strength

Rubber binders provide the highest strength due to their polymer chain structure, making them suitable for large compacts. PEG offers moderate strength ideal for complex geometries, while paraffin wax has the lowest binding strength as it relies solely on physical bonding.

Debinding Process

Paraffin wax can be removed at relatively low temperatures between 200 to 400°C, though carbon balance must be carefully controlled. PEG requires aqueous pre-debinding followed by thermal cycling, but is sensitive to moisture. Rubber binders demand high-temperature pyrolysis above 500°C and carry risks of sulfur contamination.

Residue Effects

Paraffin may leave carbon residues that affect the WC/Co ratio, requiring adjustment of carbon potential during sintering. PEG leaves virtually no residue, making it excellent for high-purity alloys. Rubber can leave sulfur residues that reduce the alloy’s corrosion resistance.

Economic Considerations

Paraffin wax has the lowest initial cost but may incur additional expenses for carbon management. PEG provides the best value for precision components and mass production. Rubber is the most expensive option and is only justified for specialized heavy-duty applications.

Selection Summary

For cost-sensitive production where simple processes are preferred, paraffin wax is suitable but requires careful control of dimensional stability during debinding. When high precision and environmental considerations are priorities, PEG is the optimal choice though it needs humidity-controlled storage. Rubber binders are reserved for applications requiring maximum strength and large components, provided that high-temperature debinding equipment is available.

Modern developments are creating hybrid binder systems that combine the advantages of these materials, such as PEG’s performance with paraffin’s cost benefits through advanced formulation techniques.

]]>

Contamination

Characteristics: Contamination is characterized by the presence of unevenly sized pores inside the cemented carbide product, with corresponding surface protrusions or holes.

If the surface is slightly contaminated and can be machined without leaving holes, the product can be considered qualified and released.

If the surface is severely contaminated or exhibits blistering, it should be classified as scrap.

Causes of Contamination

During the high-temperature sintering stage, gases generated by internal reactions in the sintered body escape or migrate to the surface. By this time, the liquid phase has already begun to solidify, leaving behind small pores that cannot recover in time, and the gases migrating to the surface are not completely expelled.

Certain difficult-to-reduce oxides are only reduced at the temperature where the liquid phase forms. The pressure of the gases produced by reduction exceeds the resistance of the liquid phase contraction, leading to blister formation.

1.Excessive temperature (over-sintering) causes a significant increase and aggregation of the liquid phase, resulting in blistering.

2.Impurities in the pressed blocks, such as carbide chips or copper wires, can also cause blistering (contamination).

3.Severe delamination in the pressed product can also manifest as blistering during sintering.

Sources of Contamination

1.Oxidized block materials, oxidized granular materials, and defective pressed blanks.

2.Metal impurities: Screen mesh debris, cobalt chips.

3.Non-metal impurities: Ceramic fragments, glass fragments, boat-filling materials, dust, brush debris, etc.

4.Forming agents: Unremoved mechanical impurities, unfiltered gel, uneven forming agents, aged forming agents, etc.

Deformation

Characteristics: The geometric shape of the carbide product undergoes irregular changes, and warped products exhibit a regular curved deformation on a specific plane.

For such deformedcarbide products, inspections should be conducted according to standards or product drawings. Products that exceed tolerance limits should be returned to the production unit for reprocessing, and those that cannot be reprocessed should be classified as scrap.

Causes of Deformation Defects

1.Uneven density of the pressed product: This leads to uneven shrinkage during sintering. Areas with higher density shrink less, while areas with lower density shrink more.

2.Uneven carbon atmosphere around the pressed blank: This causes deformation of the product.

3.Uneven temperature environment during sintering: The pressed blank deforms due to temperature inconsistencies in the sintering environment.

4.Other reasons: Improper loading of the sintering boat, uneven placement of the base plate, etc.

Peeling

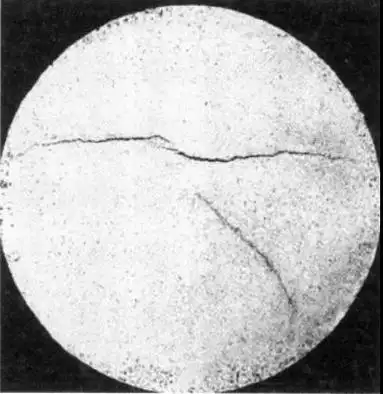

Characteristics: Peeling is characterized by the appearance of irregular branch-like cracks, cracks, or flaking at the edges and corners of the alloy product. In mild cases, it presents as a network of cracks, while in severe cases, small pieces may peel off. In extreme cases, the product may crack and peel off entirely, with cotton-like carbon black deposits clearly visible at the peeling sites. Carbide products with peeling are directly classified as scrap.

Causes of Peeling

1.High concentration of carbon-containing gases in the low-temperature zone: High concentrations of carbon-containing gases penetrate weak areas of the product (such as edges and corners, which often have lower density or significant elastic aftereffects). Under the catalytic action of cobalt, carbon precipitation reactions occur:

CH=C+H 2

CO =?C+CO

The precipitated carbon disrupts the continuity of the carbide, leading to peeling. In other words, the decomposition of carbon-containing atmospheres into large amounts of free carbon is the primary cause of peeling.

2.Vacuum dewaxing stage: If the dewaxing temperature exceeds 400°C (typically 375°C), it reaches the pyrolysis temperature of paraffin, generating low-molecular-weight paraffin, olefins, and free carbon. As the temperature continues to rise, paraffin pyrolysis intensifies. At this stage, the sintered body becomes porous and loose, significantly reducing its strength and making it difficult to withstand the impact of hydrocarbon gases generated by paraffin pyrolysis, leading to peeling.

Process Parameters Affecting Peeling

(1) Boat pushing speed and heating rate in the low-temperature zone

(2) Moisture content in hydrogen

(3) Loading amount in the boat

(4) Catalytic effect of cobalt

Carburization

Carburized carbide products have a shiny, oily black surface, with fine graphite dots or nest-like spots visible on the cross-section. In severe cases, the product may feel lubricated to the touch and leave black marks. Carburization generally affects the performance of the product and should be evaluated based on the specific grade and intended use. Non-compliant products should be returned to the production unit for reprocessing.

Causes of Carburization

1.Excessive total carbon content in the mixture

2.High carbon content in the filler material

3.High concentration of hydrocarbons in the low-temperature zone atmosphere

4.Diffusion of carbon from graphite boats into the sintered body

Rapid heating rate and short duration during the removal of the forming agent, causing the forming agent to decompose and generate free graphite, leading to carbide carburization

Sources of Free Carbon

1.Decomposition of the forming agent during the dewaxing (degumming) process

2.Diffusion of carbon from graphite boats

3.Control of the sintering atmosphere in the vacuum furnace

Decarburization

Decarburized carbide products exhibit white bright spots or shiny streaks on the surface, with silver-white shiny spots or tadpole-shaped pits visible on the fracture surface. The microstructure may show the presence of the η phase. Decarburization generally affects the performance of the product, and decarburized carbide products should be returned to the production unit for reprocessing.

Causes of Decarburization

1.Decarburization reaction during hydrogen sintering

The reaction between WC in the product and H? generates CH?. This reaction occurs throughout the sintering process and intensifies as the temperature rises.

At the furnace entrance, before complete shrinkage, decarburization occurs both internally and externally in the product.

At the furnace exit, after the product has shrunk, decarburization occurs on the surface. The intensity of the reaction depends on the flow rate of H?. The CH? generated by this reaction decomposes at high temperatures, causing carburization of the product.

Moisture in the furnace atmosphere reacts with WC or C at temperatures above 825°C:

H2O+WC→W+H2+CO

H2O+C→CO+H2

This reaction also occurs at both the entrance and exit of the furnace. Before complete shrinkage, it causes internal and external decarburization, while at the furnace exit, it causes surface decarburization.

Decarburization reaction during vacuum sintering

The deoxidation reaction during vacuum sintering occurs because the pressed blank contains oxygen, which is reduced by free carbon and carbon in WC during sintering. The reactions are:

MeO+C→Me+CO

MeO+2C→MeC+CO

This reaction also occurs at both ends of the furnace entry and exit. Before complete contraction, the U-shaped product causes decarburization both inside and outside. At the exit end, it causes decarburization on the product’s surface.

2.Vacuum sintering decarburization reaction

The deoxidation reaction after vacuum sintering occurs because the compact contains oxygen, which is reduced by free carbon and carbon in WC during sintering. The reaction is: MeO + C == Me + CO, MeO + 2C == MeC + decarburization reaction has occurred.

Mixing

The surface of the alloy product mixed with materials resembles the skin of a bitter melon, with uneven alloy structure. Its cross-section is different from the general dirty holes, often showing spots of varying sizes and shapes, as well as uneven surfaces. Different grades of organizational structure can be seen in the microstructure. Mixed carbide materials affect performance and are generally considered scrap, but slightly mixed materials can be inspected and treated according to the standard for cross-sectional contamination.

Causes of mixing

1.Mixing before pressing

2.The influence of certain impurity elements, such as aluminum, sulfur, silicon, phosphorus, and boron, which can cause WC grain growth during liquid-phase sintering, with phosphorus having the most significant effect.

Over-sintering

Over-sintering products have enlarged surface grains and coarser cross-sectional structure. In mild cases, only a larger number of shiny spots are observed, while in severe cases, the surface sometimes shows blisters or a honeycomb appearance. Over-fired products should be considered scrap.

Causes of over-sintering

1.Excessive sintering temperature – grain growth

2.Prolonged holding time – grain growth

Under-sintering

Under-fired alloy products have a loose structure, dark surface color, and no metallic luster. Vacuum-sintered products have a gray-white surface, larger shiny spots on the cross-section, and a noticeable water absorption phenomenon. Under-fired products should be returned to the production unit for treatment.

Poor pressing

This type of alloy product, due to insufficient compacting density and excessively large hole size, does not completely disappear during the sintering process. The product’s surface shows loose particles, mainly appearing at the blade edges and corners. In severe cases, fine cracks appear on the surface, and the cross-section shows triangular or strip-shaped holes. If only the surface is slightly poorly pressed, and the cross-section and metallography do not show this phenomenon, it can be released as a qualified product. If the surface is poorly pressed, and the cross-section and metallography also show this phenomenon, then this type of product should be treated as scrap.

Causes of poor pressing

Overly hard, overly coarse granular materials, uneven distribution of granular materials in the mold cavity, low compact single weight, low pressing pressure, or local low density.

Conclusión

The above only analyzes several reasons for the non-conformance of carbide products. In actual production, there may be various other issues, which require us to further improve our understanding, analyze the causes, and propose specific countermeasures. After the occurrence of non-conformance, it is necessary to seriously analyze our production process, identify the causes, and make improvements. Generally, attention should be paid to details, especially the usual practices that are often taken for granted. Only by truly focusing on the details can we reduce problems and avoid quality issues. Therefore, it is said: “Details determine success or failure.”

]]>Electrolytic Grinding of Carbides

Electrolytic grinding combines electrochemical machining and mechanical grinding to process carbides, with electrochemical machining playing the dominant role (80%-90%), while mechanical grinding accounts for only 10%-20%. The productivity of this method is 4-8 times higher than conventional mechanical grinding. Additionally, it allows for easy adjustment of electrical parameters, merging rough and fine machining into a single step, thereby shortening production cycles and reducing costs. This makes electrolytic grinding an ideal method for machining carbides.

Structure and Principle

Electrolytic grinding primarily consists of three main components: a DC power supply, a machine tool, and a hydraulic system, as shown in Figure 1.

During electrolytic grinding, the carbide?workpiece is connected to the positive pole of the DC power supply, while the diamond conductive grinding wheel is connected to the negative pole. A certain contact pressure is maintained between the two, and an electrolytic gap is preserved between the workpiece and the protruding abrasive particles (diamond) on the grinding wheel. Electrolyte is supplied into this gap. When the power is turned on, an electrochemical reaction occurs on the workpiece surface, causing the carbide?to electrolyze and form a thin oxide layer (electrolytic film) on its surface. This oxide layer is much softer than the carbide?itself. The high-speed rotating diamond grinding wheel continuously removes this oxide layer, which is then carried away by the electrolyte. This exposes a fresh surface of the workpiece, allowing the electrolytic reaction to continue. The alternation between electrolysis and oxide layer removal results in the continuous machining of the carbide, forming a smooth surface with precise dimensions.

Electrochemical Reactions in Electrolytic Grinding of Carbides

carbides are primarily composed of hard carbides (WC, TiC) with a metal binder (Co), formed through pressing and sintering. According to electrochemical reactions, cobalt begins to dissolve at 1.2V, forming Co(OH)?:

?

Tungsten carbide starts to dissolve at 1.7V, while titanium carbide begins to dissolve at 3.0V:

The electrolytic efficiency is the percentage of theoretical electrolysis to actual electrolysis. In electrolytic grinding, the electrolytic efficiency of carbides ranges from 70% to 90%.

Machining Parameters

Power Supply

The power supply for electrolytic grinding is a DC source with a voltage range of 4-14V and a current range of 50-3000A. The machining gap is approximately 0.03mm (roughly equal to the size of the abrasive particles).

Electrólito

Electrolytic grinding is based on electrochemical dissolution. The choice of electrolyte significantly affects productivity, precision, and surface quality. After extensive testing, the following three electrolyte compositions were selected:

Electrolyte 2:

NaNO?: 6.3%, NaNO?: 0.3%, Na?HPO?: 2%, pH: 8-9, Na?B?O?: 1.4%, H?O: 90%

Electrolyte 3:

NaNO?: 5%, NaNO?: 1.6%, Na?HPO?: 1%, pH: 7-8, Na?B?O?: 1.5%, NaCl: 0.05%, C?H?(OH)?: 0.3%, H?O: Balance

The electrolyte is used at a temperature of 22-30°C and a pressure of 14-70kPa. The filter precision is 50-100μm, and the nozzle, installed close to the workpiece, is equipped with an air scraper.

Diamond Electrolytic Grinding Wheel

Diamond conductive grinding wheels are typically used for electrolytic grinding of carburos due to their regular shape, high hardness, and ability to maintain a consistent electrolytic gap, resulting in high productivity. During fine grinding, mechanical grinding can be performed independently. Diamond electrolytic grinding wheels can be categorized into metal-bonded and electroplated diamond wheels. The former is used for flat and cylindrical grinding of carbide?molds, while the latter is used for electrolytic form grinding of large batches of single-shaped workpieces and internal cylindrical grinding of small holes. The grinding pressure is generally around 30N/cm2. The linear speed of the grinding wheel is typically 1200-2100 m/min, and the contact length with the workpiece should not exceed 19mm to prevent electrolyte boiling.

Material Removal Rate and Precision

The material removal rate of carbides is proportional to the current density. Under specific alloy materials, electrolyte combinations, and electrolyte boiling points, the current density is limited by the anode dissolution rate. The productivity of electrolytic grinding of carbides is generally 0.16cm3 per 100 A/min. At a current density of 77.5A/cm2, the feed rate for face grinding is 25mm/min, with a typical dimensional accuracy of ±0.025mm per pass. If an additional mechanical grinding pass is performed without electrolysis, the accuracy can reach ±0.002mm. When grinding external contours, the corner radius on the workpiece is about 0.025mm, while the roundness radius for internal contours is limited to 0.25-0.38mm. The material removal rate in electrolytic grinding is 4-8 times higher than that of conventional grinding methods.

Surface Quality

The surface roughness achieved by electrolytic grinding of carbides is generally Ra 0.2-0.8μm, but it can reach Ra 0.025-0.1μm. The surface of the workpiece resembles that obtained by metallographic polishing, and the hardness of the workpiece does not affect the surface quality. During machining, the processed surface does not develop internal stresses or heat-affected zones, resulting in high surface integrity.

Equipment and Tools

The grinding machine must have sufficient rigidity to maintain precision even under a bending stress of 1 MPa between the grinding wheel and the workpiece. The machine requires corrosion-resistant accessories for pressurizing and filtering the electrolyte. Control equipment, fixtures, and mechanical and electrical systems should be made of suitable materials or coated to operate in a salt spray environment. Conductive diamond grinding wheels are preferred for electrolytic grinding, although non-conductive abrasive wheels can also be used, albeit with less effectiveness. The electrolyte nozzle is typically made of heat-resistant organic glass or equivalent insulating materials. Workpiece fixtures are made of copper or copper alloys. The design should ensure that the cathode and anode parts are insulated during electrolytic grinding to maintain proper machine operation.

Discussion of Key Process Parameters

Current Density and Voltage

In electrolytic grinding, current density is the primary factor determining productivity. Productivity increases with higher current density, but excessively high or low current densities can reduce machining precision and surface quality. In practice, voltage should not be increased indefinitely, as excessively high voltages can cause spark discharge, affecting surface quality. For carbide?electrolytic grinding, the optimal current density is 110 A/cm2, with practical current densities ranging from 15-60 A/cm2 and voltages from 7-10V. For rough grinding, the current is 120-300 A/cm2, while for fine grinding, it is 5-6 A/cm2.

Machining Gap

At a given voltage, a smaller machining gap results in higher current density, increased productivity, and improved surface flatness and precision. However, if the gap is too small, the electrolyte may not distribute evenly, leading to spark discharge and increased wheel wear. The typical machining gap is 0.025-0.05mm.

Grinding Pressure

Increasing grinding pressure enhances productivity, but excessive pressure reduces the electrolytic gap, increasing the risk of spark discharge. Conversely, insufficient pressure leads to incomplete removal of the oxide layer, reducing both efficiency and surface quality. Therefore, grinding pressure should be set to avoid spark discharge while ensuring complete oxide layer removal. The recommended grinding pressure is 0.2-0.5 MPa.

Contact Area Between Workpiece and Grinding Wheel

A larger contact area allows the DC power supply to deliver higher current, increasing productivity while maintaining good surface quality. Therefore, during electrolytic grinding, the grinding wheel and workpiece should maintain the largest possible contact area.

Grinding Wheel Speed

Increasing the grinding wheel speed ensures adequate and rapid electrolyte supply in the gap, enhancing mechanical grinding and productivity. However, the speed should not be excessively high. The typical linear speed of the grinding wheel is 1200-2100 m/min.

Electrolyte Supply

The electrolyte flow rate should ensure sufficient and uniform entry into the machining gap. For vertical electrolytic surface grinders, the flow rate is typically 5-15 L/min, while for cylindrical grinders, it is 1-6 L/min. The installation of the electrolyte nozzle is crucial, as it helps confine the electrolytic action to the machining gap between the grinding wheel and the workpiece. The nozzle must be firmly installed close to the outer surface of the grinding wheel and equipped with an air scraper to break the air layer on the rotating wheel’s outer edge. The electrolyte pressure is generally 14-70kPa, and the temperature is controlled between 19-33°C.

Conclusión

High Productivity

Electrolytic grinding of carbides offers 4-8 times higher productivity than conventional mechanical grinding, especially when the contact area between the conductive diamond grinding wheel and the carbide?workpiece is increased.

Excellent Surface Quality

Electrolytic grinding of carbides achieves high surface quality, with typical surface roughness of Ra 0.4μm or better, and can reach Ra 0.025μm, producing a mirror-like finish. Increasing the machining current does not significantly affect surface quality. Additionally, the processed surface does not develop internal stresses or heat-affected zones, resulting in high surface integrity unmatched by other machining methods.

High Precision

With advancements in carbide?electrolytic grinding, the use of diamond electrolytic grinding wheels that can perform both electrolytic and mechanical grinding allows for high precision. After electrolytic grinding, the power can be turned off, and mechanical grinding can be performed to achieve precision comparable to conventional mechanical grinding.

Low Grinding Wheel Wear

In electrolytic grinding, the abrasive particles in the grinding wheel primarily maintain the electrolytic gap and remove the oxide layer, reducing abrasive wear. The wear of diamond grinding wheels in electrolytic grinding is significantly lower than that in conventional mechanical grinding.

In summary, electrolytic grinding of carburos offers unique advantages over conventional machining methods, significantly improving productivity, surface quality, and precision, making it an ideal method for machining carbides.

]]>

Carbide Manufacturing Process

The process involves weighing ultra-fine WC powder and Co powder, produced by special methods, according to the composition ratio, and adding small amounts of elements such as Ti, Ta, Nb, and Cr. Wet grinding is performed using φ8 cemented carbide balls with a ball-to-material ratio of 5:1. The grinding medium is anhydrous alcohol, and the grinding time ranges from 72 to 120 hours. The slurry is dried at 80 to 100°C for about 2 to 4 hours, then mixed with glue (wax) to form granules. These are pressed into various products such as 5×5×30 and A118A, and sintered under H? protection at temperatures between 1400°C and 1500°C.

Microstructure and Physical-Mechanical Properties

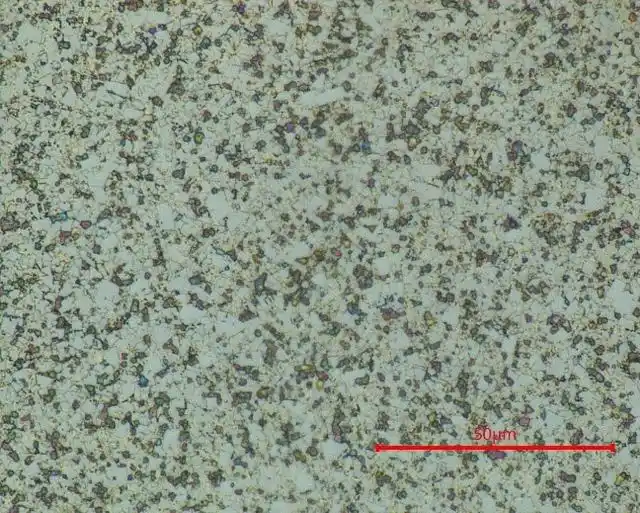

Due to the use of special raw materials and production methods different from conventional processes, and the appropriate selection of types and quantities of added elements, the YT04 carbide achieves the desired effects. Table 1 lists the performance indicators of the YT04 carbide grade from several developments, and Figure 1 shows the metallographic structure of the YT04 carbide.

From the results in Table 1 and Figure 1, the YT04 carbide has high hardness and moderate strength. The microstructure is very uniform, with grain sizes almost all less than 0.5 μm, except for a few WC grains larger than 0.5 μm. The thickness of the binder phase is also less than 0.5 μm.

Cutting Characteristics

Application Range of YT04 carbide

Due to its extremely fine WC grain size and high hardness, the YT04 carbide has very high wear resistance, red hardness, and thermal strength, along with high strength. This carbide is suitable for machining difficult materials such as ferrosilicon, vanadium-titanium cast iron, boron-added cast iron, white cast iron, high, medium, and low nickel-chromium chilled cast iron; various quenched carbide steels, tool steels, magnetic steels, high manganese steels, ultra-high strength steels, high-speed steels; tungsten-based, molybdenum-based, titanium-based non-ferrous carbides; granite, marble, glass, cast stone, high-cobalt cemented carbide, steel-bonded cemented carbide, and some ceramic materials and engineering plastics for precision turning, milling, planing, and cutting. It can also be used for semi-finishing, with a durability 1 to 10 times higher than traditional YT, YG, and YM grade cemented carbides. The surface finish of the machined workpiece can reach up to ▽8. It shows particularly satisfactory results when used for low-speed cutting to replace high-speed steel tools.

Usage Conditions of YT04

According to relevant literature, the YT04 carbide should be used with the following parameters:

(1) Main cutting edge angle (K,) ≤ 45°.

(2) Rake angle (Y.) = 0 to -8°, cutting edge inclination angle (λ) = -5 to -9°.

(3) Clearance angle (a.) and tool nose radius (Ye). Since the YT04 carbide is only suitable for finishing and semi-finishing, a larger clearance angle should be chosen to reduce friction between the flank face and the workpiece surface, typically around 10°. The tool nose radius should be 1 to 2 mm.

(4) Cutting speed (V). The cutting speed should be determined based on specific conditions. For workpieces with HRC60 and above, a cutting speed of 10 m/min is ideal, and should not exceed 20 m/min to avoid tool tip reddening and burning. For materials around HRC45, the cutting speed can be increased to about 50 m/min, but should not exceed 100 m/min to fully utilize the tool’s excellent performance. For materials like 35CrMoA (HB≈229), the cutting speed can even be as high as 200 m/min or more.

(5) Depth of cut (αp). This depends on the surface quality requirements of the workpiece. For a finish of 76 or above, the cutting depth can be set at 0.07 to 0.12 mm. If the precision requirements are not strict, it can be set at 0.2 to 0.4 mm.

(6) Feed rate (f). YT04 is generally used for finishing, with a feed rate typically of 0.2 to 0.3 mm. For semi-finishing, the feed rate can be increased to 0.4 to 0.5 mm. It should be noted that if machining high-hardness materials around HRC65, too large a feed rate can cause chipping.

Cutting Examples

Here are some examples of YT04 carburo in practical use:

- Material: Cast stone, workpiece size: Φ160×1500, external turning, tool geometry parameters: K,=45°, Y.=12°, α=6°, λ=-6°; cutting parameters: V=6 m/min, f=0.1 mm/r, ap=1.00 mm.

- Material: Quenched bearing steel, HRC62, workpiece: Φ30×50 mm, external turning; tool geometry parameters: K=40°, Y.=15°, α.=10°, Re=0.5 mm. Cutting parameters: V=61.8 m/min, f=0.14 mm/r, αp=0.4 mm. Test results: After machining 11 pieces per cutting edge, the cutting path reached 2472 m, with basically no wear on the cutting edge, and a workpiece surface finish of 76.

Usage Instructions

1.Strictly follow the provided tool geometry parameters and cutting conditions.

2.YT04 carbide is not suitable for intermittent cutting.

3.YT04 carbide can be sharpened with green silicon carbide wheels. Using diamond oil stones for edge honing can further improve performance.

Conclusión

Overall, the YT04 carburo, with its extremely fine grain size and excellent physical-mechanical properties, performs exceptionally well in machining difficult-to-process materials and is suitable for various precision machining applications.

]]>

Sample Preparation and Experimental Conditions

Material Selection

To compare the corrosion resistance of WC-based cemented carbides, four groups of test materials were selected:

(1) WC-Co alloy;

(2) WC-Co alloy with a small amount of heterogeneous carbides;

(3) WC-Ni·Mo·Co·Cr alloy;

(4) Low binder phase content alloy.

Corrosion Conditions

Corrosion Media: Hydrochloric acid, sulfuric acid, nitric acid, citric acid (H?Cit), acetic acid (HAC), sodium hydroxide (50%), and potassium hydroxide (50%).

Test Temperatures: 20°C, 40°C, 80°C, and boiling point. Alkali solutions were only tested at the boiling point.

Corrosion Time: 24-72 hours for low temperatures and 6-24 hours for the boiling point.

Corrosion Rate Calculation: The corrosion rate (A) is calculated as the amount of material corroded per unit area per day, expressed in mg/dm2·day (abbreviated as mdd).

Results and Discussion

Relationship Between Corrosion Rate and Binder Phase Content in WC-Based Cemented Carbides

The corrosion rate of WC-based cemented carbides is related to the content of the binder phase, regardless of the binder’s composition. Alloys with higher binder content exhibit higher corrosion rates. For WC-Co alloys, when the cobalt content exceeds 2%, the corrosion rate increases sharply. In 5% HNO?, the corrosion rate of WC-2% Co alloy still exceeds the acceptable limit. However, the corrosion rate of WC-Ni·Mo·Co·Cr alloy with 2% Ni·Mo·Co·Cr meets the usage requirements under all tested conditions. Even in highly corrosive nitric acid, its corrosion rate is only 196.6 mdd, corresponding to corrosion resistance grade B (less than 250 mdd).

The difference in corrosion rates among alloys with varying cobalt content is not significant at room temperature. However, as the temperature increases, the difference becomes more pronounced. At room temperature, increasing the cobalt content from 2% to 20% results in a corrosion rate change of only 12-30 mdd. At the boiling point, the corrosion rate increases from 20 mdd for low cobalt content to 6×10? mdd for high cobalt content.

Effect of WC Grain Size on Corrosion Rate

Fine-grained alloys have higher interfacial energy and greater internal stress in the binder phase, resulting in lower corrosion resistance. Therefore, fine-grained alloys are not recommended for improving resistance.

Effect of Small Amounts of Heterogeneous Carbides on Corrosion Rate

Comparing WC-Co cemented carbides with small amounts of heterogeneous carbides reveals that their effects on corrosion rates vary:

Cr?C?: A small amount of Cr?C? can improve the alloy’s corrosion resistance. Even though alloy No. 9 has finer WC grains than alloy No. 4, its corrosion resistance is superior due to the addition of Cr?C?.

TaC: The addition of a small amount of TaC has no significant effect on resistance. Comparing alloy No. 4 with alloy No. 7 (which contains 2% TaC), the corrosion rates are similar. Adding 5% TaC also does not improve corrosion resistance.

Mo?C: Adding less than 1% Mo?C can significantly enhance resistance. This is because Mo?C readily dissolves in the γ phase, thereby improving the alloy’s corrosion resistance.

Thus, adding small amounts of Cr?C? or Mo?C is beneficial for improving the corrosion resistance of cemented carbides.

Effect of Graphite and η1 Phase on Alloy Corrosion Rate

The presence of graphite and η1 phase not only significantly affects the physical and mechanical properties of the alloy but also has a notable impact on the corrosion rate. For the tested media, the presence of graphite significantly reduces the alloy’s corrosion resistance. When graphite is present, the solubility of tungsten (or molybdenum) in the binder phase drops below 2-3%, reducing the binder phase’s resistance. Additionally, according to corrosion theory, graphite increases the electrochemical corrosion effect of micro-galvanic cells between phases. Therefore, cemented carbides used as corrosion-resistant materials must avoid the formation of graphite.

In contrast, the η1 phase significantly enhances the alloy’s corrosion resistance. The presence of η1 phase indicates carbon deficiency in the alloy, allowing the binder phase to dissolve a large amount of W (or Mo), typically 10-13%. This composition of the binder phase is more corrosion-resistant. Moreover, the transformation of a certain amount of binder into η1 phase further improves the alloy’s resistance. Thus, under carbon-deficient conditions, the alloy’s corrosion resistance increases sharply compared to normal alloys.

Given these findings, the carbon content should be controlled at the lower limit of the two-phase region or allow the formation of a small amount of dispersed η1 phase, provided that the mechanical properties are not excessively compromised. This results in an ideal microstructure with high corrosion resistance.

Relationship Between Binder Phase Corrosion Resistance and Alloy Corrosion Rate

While the mechanical properties of WC-Ni alloys are generally lower than those of WC-Co alloys, their corrosion resistance is superior, especially under low-carbon conditions. However, alloys with pure nickel as the binder often fail to meet usage requirements, leading to the development of complex nickel-based binders. Ni-Mo alloys exhibit excellent resistance to acid and alkali corrosion, making them suitable as binders for WC-based alloys. This study tested the corrosion resistance of alloys with Ni-Mo-Co-Cr (83:15:1:1) as the binder. The overall trend in corrosion rates for this series is similar to that of WC-Co alloys, but the values are significantly lower. Particularly, low binder content alloys meet the specified usage requirements for all tested media, with corrosion rates below 250 mdd. Additionally, the corrosion rate of WC-Ni·Mo·Co·Cr alloys does not change significantly with increasing temperature.

In summary, improving the corrosion resistance of WC-based cemented carbides depends on enhancing the binder phase’s corrosion resistance, which is particularly effective for low binder content alloys.

Activated Sintering of WC-Based Low Binder Content Alloys

An important approach to improving the resistance of WC-based cemented carbides is to reduce the binder content, provided that the physical and mechanical properties meet usage requirements.

To enhance the performance of sintered products, activated sintering is often employed. The properties of low binder content alloys are closely related to the uniformity of component mixing. Therefore, chemical mixing to produce composite powders, intensified ball milling, and activated sintering processes were adopted. For comparison, conventional processes were also used to prepare alloys with the same composition.

Comparison of Corrosion Resistance Among Different Alloys

Corrosion rates are classified into three grades: A (<25 mdd), B (<250 mdd), and C (<500 mdd). For WC-Co alloys, only low binder content alloys exhibit comprehensive corrosion resistance. In contrast, WC-Ni·Mo·Co·Cr alloys maintain considerable corrosion resistance even with 10% binder content. Notably, WC-2% Ni·Mo·Co·Cr alloys demonstrate excellent resistance under all tested conditions.

WC-Ni·Mo·Co·Cr alloys are widely used in manufacturing ballpoint pen tips. These alloys outperform traditional WC-Co·Ni·Cr alloys in various properties, are easier to produce, and have lower production costs, making them ideal materials for corrosion-resistant ballpoint pen tips.

Conclusions

1.The corrosion resistance of WC-based cemented carbides is primarily determined by the resistance of the binder phase. Lower binder content results in better condition. Alloys with Ni·Mo·Co·Cr as the binder exhibit significantly lower corrosion rates than WC-Co alloys, especially those with low binder content.

2.The corrosion rate of WC-based cemented carbides is related to the grain size of the hard phase. Finer grains lead to poorer corrosion resistance.

3.Small amounts of heterogeneous carbides, such as Cr?C? and Mo?C, can improve the resistance of WC-Co alloys, while TaC has little to no effect.

4.Graphite reduces the resistance of WC-based alloys, whereas the η1 phase significantly enhances it. Therefore, the ideal corrosion-resistant alloy should have carbon content controlled at the lower limit of the two-phase region or allow the formation of dispersed η1 phase without excessively compromising mechanical properties.

5.Low binder content alloys with good corrosion resistance can be prepared using chemical mixing to produce composite powders, intensified ball milling, and activated sintering processes, achieving high physical and mechanical properties.

6.The study of the corrosion resistance of WC-based cemented carbides provides a basis for their broader application.

]]>

Chemical Composition

Tungsten carbide is a compound formed by tungsten (W) and carbon (C) atoms in a 1:1 ratio, with the chemical formula WC. This compound has very stable chemical bonds and can maintain its chemical stability in high temperatures and harsh chemical environments. Tungsten is a metal element with very high density and melting point. When carbon is combined with tungsten to form carbides, the material not only possesses the high strength characteristics of tungsten but also greatly increases in hardness due to the addition of carbon. This makes tungsten carbide a material that combines high hardness with high-temperature stability, making it very suitable for preparing coatings that require extremely high wear resistance and corrosion resistance.

Microstructure

The microstructure of tungsten carbide coatings mainly includes grain size, porosity, and coating thickness. These microscopic characteristics have a direct impact on the performance of the coating. Typically, tungsten carbide coatings have a fine and uniform grain structure, which provides higher hardness and wear resistance. The density of the coating is also a key factor; an ideal tungsten carbide coating should have an extremely low porosity to prevent the penetration of corrosive media and enhance the mechanical strength and adhesion of the coating.

In industrial applications, by optimizing the preparation process, the grain size and thickness of the coating can be controlled, thereby adjusting the hardness, toughness, and wear resistance of the coating. For example, tungsten carbide coatings used under high-temperature conditions typically require a larger grain structure to improve high-temperature stability, while in severely abrasive environments, finer grains help to enhance the coating’s wear resistance.

Performance and Characteristics of Tungsten Carbide Coatings

With their outstanding hardness, wear resistance, corrosion resistance, and high-temperature stability, tungsten carbide coatings have become one of the widely used surface engineering technologies in industrial applications. To better understand the practical application effects of tungsten carbide coatings, this section will discuss their performance and characteristics in detail from four aspects: wear resistance, corrosion resistance, high-temperature stability, and mechanical properties.

Abrasive Property

The High Hardness Characteristics of Tungsten Carbide

The wear resistance of tungsten carbide coatings is derived from their ultra-high hardness, which excels in resisting mechanical wear. The hardness of tungsten carbide is close to 9 on the Mohs scale, making it one of the hardest compounds known in materials. This high hardness enables tungsten carbide coatings to effectively resist wear when in contact with other hard materials, reducing the loss of the material surface.

The Wear Mechanisms of Coatings

The wear mechanisms of tungsten carbide coatings mainly include abrasive wear, adhesive wear, and fatigue wear. In abrasive wear, hard particles or debris slide or roll between two contact surfaces, leading to the scraping or cutting of the coating material. Due to the high hardness of tungsten carbide, it can effectively resist this type of wear. In adhesive wear, when two surfaces move relative to each other under high pressure, the coating material may be torn or transferred, but the high hardness and low coefficient of friction of the tungsten carbide coating can significantly slow down this process. Fatigue wear occurs under repeated mechanical stress, where micro-cracks form on the coating surface and gradually expand, eventually leading to the flaking off of the material.

Performance of Wear Resistance in Different Application Scenarios

Tungsten carbide coatings exhibit excellent wear resistance across various application scenarios. For instance, in cutting tools, tungsten carbide coatings can maintain the sharpness of the cutting edge and extend the service life of the tool; in mining and oil drilling equipment, tungsten carbide coatings can effectively resist wear from hard rock and gravel, reducing the maintenance frequency of the equipment; in the automotive industry, tungsten carbide coatings can be used in engine components to significantly improve the wear resistance and service life of the parts. These applications demonstrate that tungsten carbide coatings can maintain their integrity and functionality in extreme wear environments.

Anti-corrosive Property

The Stability of Tungsten Carbide in Corrosive Environments

Tungsten carbide coatings not only possess excellent wear resistance but also demonstrate good corrosion resistance, particularly in acidic and alkaline environments. The chemical inertness of tungsten carbide allows it to remain stable in a variety of corrosive media, with a low propensity for chemical reactions. This characteristic enables tungsten carbide coatings to protect the substrate from chemical corrosion in many industrial applications, thereby extending the service life of the equipment.

Tolerance of Coatings under Acidic and Alkaline Conditions

Under acidic conditions, such as in strong acid environments like sulfuric acid and hydrochloric acid, a dense oxide film forms on the surface of the tungsten carbide coating. This film effectively prevents further erosion by acidic media, thereby protecting the substrate. In alkaline environments, tungsten carbide coatings also exhibit good tolerance. The chemical stability of the coating resists erosion by strong alkalis, preventing corrosive damage to the substrate. This excellent corrosion resistance has led to the widespread application of tungsten carbide coatings in fields with stringent corrosion requirements, such as chemical engineering and marine engineering.

Comparison with Other Corrosion-Resistant Materials

Compared to other corrosion-resistant materials, such as stainless steel and nickel-based alloys, tungsten carbide coatings have higher hardness and a lower corrosion rate. In environments with dual challenges of high wear and high corrosion, tungsten carbide coatings often provide longer periods of protection, reducing maintenance and replacement costs. For instance, in applications in marine environments, tungsten carbide coatings can resist the corrosion of seawater for extended periods, far outperforming traditional metal coatings.

High-temp Stability

Physical and Chemical Changes of Coatings under High-Temperature Conditions

The stability of tungsten carbide coatings in high-temperature environments makes them an ideal choice for high-temperature applications. At high temperatures, the chemical structure of tungsten carbide remains stable without decomposition or phase transformation. The high-temperature stability of the coating is not only reflected in the maintenance of its hardness but also in its oxidation resistance. Tungsten carbide can form a stable oxide film at high temperatures, which effectively prevents further oxidation, thereby protecting both the coating and the substrate.

Case Analysis of High-Temperature Applications

Tungsten carbide coatings are widely used in various equipment and components in high-temperature environments. For example, on the blades of gas turbines, tungsten carbide coatings can resist the erosion and oxidation caused by high-temperature combustion gases, extending the service life of the blades. In metal cutting tools, tungsten carbide coatings can maintain the sharpness of the tools under high-temperature cutting conditions, reducing tool wear and replacement frequency. Additionally, in oil drilling, tungsten carbide coatings can maintain their structural integrity in high-temperature and high-pressure environments, preventing premature equipment failure.

Factors Affecting High-Temperature Stability

The high-temperature stability of tungsten carbide coatings is influenced by various factors, including the thickness of the coating, its microstructure, and the nature of the substrate. A thicker coating generally provides better thermal insulation, slowing down the impact of high temperatures on the substrate. The microstructure of the coating, such as grain size and porosity, also affects its performance at high temperatures. Optimizing these factors can further enhance the high-temperature stability of tungsten carbide coatings, meeting the needs of different industrial applications.

Mechanic Property

Elastic Modulus and Hardness of Tungsten Carbide Coatings

The mechanical properties of tungsten carbide coatings are largely determined by their elastic modulus and hardness. The elastic modulus is a measure of a material’s ability to resist elastic deformation; tungsten carbide coatings have a high elastic modulus, which allows them to maintain stability in shape and size under high stress conditions. Hardness, on the other hand, is a measure of a material’s ability to resist plastic deformation; the high hardness of tungsten carbide coatings makes them less prone to deformation or wear when in contact with hard materials.

Impact and Fatigue Performance of Coatings

The impact performance of tungsten carbide coatings is demonstrated by their ability to maintain structural integrity under high-impact conditions, with a lower likelihood of spalling or cracking. This is particularly important in applications that require protection against high kinetic energy impacts, such as mining equipment and tool surface protection. Fatigue performance refers to a material’s ability to resist the formation and propagation of fatigue cracks under repeated cyclic stresses. Tungsten carbide coatings exhibit excellent fatigue resistance in fatigue tests, maintaining their mechanical properties over long periods of cyclic stress, thereby extending the service life of the coating.

Mechanical Properties Testing and Result Analysis

When testing the mechanical properties of tungsten carbide coatings, methods such as nanoindentation testing, microhardness testing, and fatigue testing are commonly used. Nanoindentation testing measures the coating’s elastic modulus and hardness, with results showing that the hardness of tungsten carbide coatings is significantly higher than that of most metal coatings. Microhardness testing further verifies the uniformity of the hardness distribution of the coating at the microscale. Fatigue testing assesses the fatigue life of the coating through cyclic stress tests of repeated loading and unloading, and the results indicate that tungsten carbide coatings exhibit outstanding durability under high-stress cycling conditions.

Application Fields of Tungsten Carburo Coatings

Thanks to their outstanding physical and chemical properties, tungsten carbide coatings have been widely used in various industrial fields. Whether it’s the demand for wear resistance in extreme environments or the requirement for stability under high temperature and pressure conditions, tungsten carbide coatings can provide reliable solutions. The following will discuss in detail the role and impact of tungsten carbide coatings in four main application fields: aerospace, tool manufacturing, oil and gas, and the automotive industry.

Aerospace

The application of tungsten carbide coatings in the aerospace field mainly focuses on turbine blades, gas turbine components, landing gears, and other key components. Turbine blades are prone to thermal fatigue and high-temperature oxidation due to long-term exposure to high-temperature and high-pressure environments. Tungsten carbide coatings can effectively enhance the wear resistance and oxidation resistance of the blade surfaces, extending the service life of the blades while reducing maintenance frequency. Additionally, tungsten carbide coatings are widely used in aircraft landing gear components, which endure significant friction and impact during takeoff and landing. The application of the coatings significantly improves the durability and safety of these components.

Future Development of Coating Technology in Aerospace

With the continuous advancement of aerospace technology, the requirements for material performance are also increasing. In the future, tungsten carbide coatings will continue to play a significant role in material lightweighting, high-temperature oxidation resistance, and adaptability to extreme environments. Particularly in the development of new hypersonic aircraft and space exploration vehicles, the application prospects of tungsten carbide coatings will be even broader. By combining with other high-performance materials, such as composites and nanomaterials, tungsten carbide coatings will demonstrate greater potential in meeting the increasingly stringent technical requirements of the aerospace industry.

Tools Manufacture

Application of Tungsten Carbide Coatings in Cutting Tools

Cutting tools are the core equipment in industrial manufacturing, widely used in metal processing, automotive manufacturing, aerospace, and electronics, among other fields. Since cutting tools need to operate under high-intensity and high-speed machining conditions, the surface materials must possess extremely high hardness and wear resistance. Tungsten carbide coatings, with their ultra-high hardness and excellent wear resistance, have become the ideal choice for the manufacturing of cutting tools.

The Impact of Coatings on Tool Life

During the cutting process, tool wear is a key factor affecting machining accuracy and efficiency. Tungsten carbide coatings can significantly extend the service life of cutting tools, reducing wear and the frequency of tool replacement. The high hardness of the coating allows the tool to maintain its sharpness during cutting and resist the heat generated by high temperatures and friction, preventing edge chipping and blunting. Experimental data show that cutting tools coated with tungsten carbide can have their service life extended by 2 to 3 times or more, while also improving the surface finish and precision of the machined parts.

Outlook for Coating Technology in Tool Manufacturing

As the demand for high-precision and high-efficiency machining increases in the manufacturing industry, the future of tool manufacturing will rely more heavily on advanced coating technologies. The application of tungsten carbide coatings will be further expanded, especially in the fields of ultra-high-speed cutting, dry cutting, and micro-machining. Future coating technologies will place more emphasis on the development of nanostructured coatings, as well as the application of multi-layer coatings, to further enhance the wear resistance, thermal stability, and impact resistance of tools. At the same time, the composite use of tungsten carbide coatings with other hard coating materials will also become an important direction for improving tool performance.

Application in Oil and Gas Fields

The Wear-Resistant Application of Coatings in Perforación Equipo

Drilling equipment in the oil and gas industry operates in extreme and harsh environments, typically facing challenges such as high pressure, high temperature, and severe wear. Drill bits and drill pipes are the most wear-prone components in drilling equipment. Due to its outstanding wear resistance, tungsten carbide coatings are widely applied to these key components. The application of these coatings significantly extends the service life of drilling equipment, reducing downtime and maintenance costs.

The Corrosion Resistance Performance of Tungsten Carbide in Harsh Environments