Concrete is usually the most used building material. It is a user-friendly, economical, easy to form and efficient structural material. However, it also has some disadvantages, such as low elastic modulus, small elastic range, low tensile and bending strength, and poor permeability (therefore prone to corrosion). Therefore, metal, polymer and fiber are usually used to strengthen concrete to overcome these shortcomings. It is necessary to explore hard materials other than steel, such as various metal carbides, to strengthen the performance of concrete in the form of powder and coarse particles.

Metal carbides can exist naturally and can also be produced as by-products of different industries. However, carbides have unique properties, such as hardness, wear resistance, tensile strength, neutron attenuation, heat resistance and chemical inertia. They are added to metals to make composites hard, corrosion-resistant and chemical resistant, and to make different tools. In order to obtain better effect of adding carbides to metal ceramics. Researchers began to study these carbides as concrete admixtures. Some articles show that the use of carbide slag along SCM can reduce the cement consumption in concrete. Other articles have also confirmed that this kind of carbide has better durability. Researchers used different forms of carbides, such as nanoparticles, powders, flakes or fibers. The size and shape of carbides affect their properties in composites.

Tungsten carbide (WC) is useful because it is a radiation protective material. WC in the form of nano powder provides higher radiation protection and better compressive strength. In addition, it also has excellent wear resistance, hardness and chemical stability. In addition, WC is a high-temperature refractory. It is very hard, with a stiffness of 18 – 22 GPA and a young’s modulus of 700 GPa. WC network can produce specific plasticity and high range ductility while maintaining high stiffness. It has high corrosion resistance. When exposed to air, WC will show signs of corrosion at temperatures exceeding 600 ° C. WC is also an electromagnetic radiation absorber.

WC is used alone or mixed with different metal composites to improve the strength. Because of its strength, chemical stability, rigidity and high temperature resistance, this ceramic carbide is also used to improve the mechanical properties of different composites. WC is the waste of cemented carbide metal, and SiC is also a waste.

Tungsten and tungsten carbide provide excellent gamma radiation shielding and neutron absorption. WC has synergistic effect on the wear and corrosion of composites and is used to improve the service life of composites. Scientists have found that when added to aluminum composites, mixing silicon carbide and tungsten carbide will improve compressive strength, tensile strength and wear resistance, because both carbides are harder and stronger materials.

This paper introduces the influence of carbides (silicon carbide and tungsten carbide) on the mechanical properties and permeability of concrete composites, and determines their compatibility with concrete. These two kinds of carbides are added with 1%, 2%, 3% and 4% of the weight of cement in concrete respectively. A mixed combination of 2% and 4% of the two carbides was also used. The density, compressive strength, corrosion resistance and flexural strength of concrete were tested.

Dichte

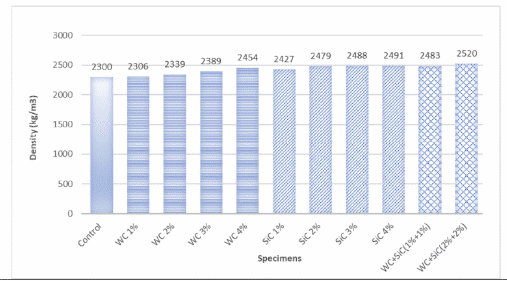

Figure 1 shows the density of all concrete samples. As shown in Figure 4, the density of concrete increases with the increase of the percentage of tungsten carbide and silicon carbide. The density of single and mixed carbides and mixed carbides reaches the maximum when the density is 4%.

By increasing the percentage of tungsten carbide in concrete, the density increases slightly. Due to the use of a lower percentage of tungsten carbide, there is no significant change in density. However, we still found that using SiC in concrete can increase the density. The typical density of WC is higher than that of concrete composition. This may be the reason why carbides increase the density of concrete, even if the percentage used is very low.

Figure?1.?Density?of?cement samples

Druckfestigkeit

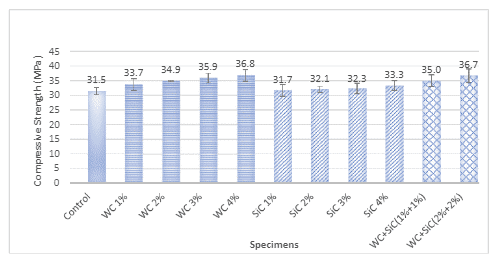

Figure 2 shows the compressive strength of carbonated concrete composites. The compressive strength of concrete increases slightly with the proportion of single carbide and mixed carbide increasing to 4%. When the WC content is 4%, the compressive strength increases by 17%. The increase in compressive strength can be attributed to the small fibrous structure of WC used in the study. It can be inferred that WC small fiber can be compared with steel fiber in terms of efficiency and cost. Typically, researchers use a fiber content of 1 – 3% of the volume of concrete. However, the carbides used in this study are additives relative to the weight of cement; Therefore, their quantity may be much lower than that of ordinary fibers. This method is designed because it is more convenient and easier to use materials with a certain percentage of cement.

Figure?2.?Compressive?Strength?of?Specimens?at?28?days.?

It is found that mixed WC can significantly improve the compressive strength of concrete. This may be because carbides form a better interface, particles accumulate better, leaving fewer voids, resulting in higher density. The increase in compressive strength can also be attributed to the inherent compressive strength of carbides as a component of concrete.

Biegefestigkeit

Strength is the most important property of concrete. The flexural strength of concrete is generally weak. Flexural strength plays a very important role in the design of concrete pavement. The increase of tensile / bending strength is the goal that researchers hope to achieve. Concrete with high tensile / flexural strength is less prone to cracks and durability problems. In addition, flexural strength is the most important performance in concrete pavement design. Now, researchers are trying to improve flexural strength by using different admixtures, fibers and other pavement concrete technologies.

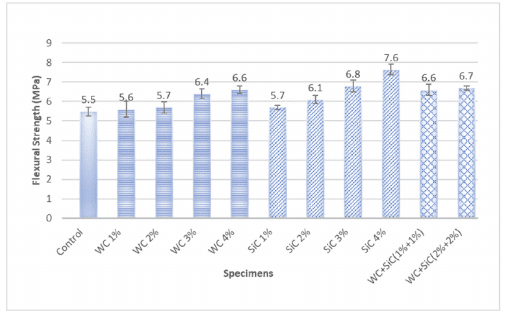

The influence of different percentages of carbides in concrete on bending quality is shown in Figure 3.

Figure 3. The bending strength of the specimen at 28 days.

By adding individual and mixed carbides, the flexural strength of concrete is significantly improved. WC has high tensile strength, but it is used in the form of small fibers. Even if the amount of use is very small, it can significantly improve the bending strength. Silicon carbide sheets do not allow prisms to be easily damaged. They provide enough reinforcement to improve the flexural strength of concrete. Although WC has high tensile / bending strength, it cannot effectively transfer tensile stress due to its small size (3 to 4mm). The higher the inherent strength of carbides, the higher the bending strength of composites. In addition, the wear resistance does not allow the composite particles to move easily. This makes the strength of the composite higher.

The mixture of WC and other carbides has high bending strength. WC is usually mixed with other metals because of its synergistic effect. Some scholars have found that WC and SiC have synergistic effects on composites. They found a synergistic effect between the two carbides in strengthening composites. The better results of WC + SiC composites may be attributed to the better interface and synergistic effect of carbide composites. ANOVA analysis found that the role of fiber percentage in improving the bending strength also confirmed the significant effect of the two carbide percentages on the bending strength.

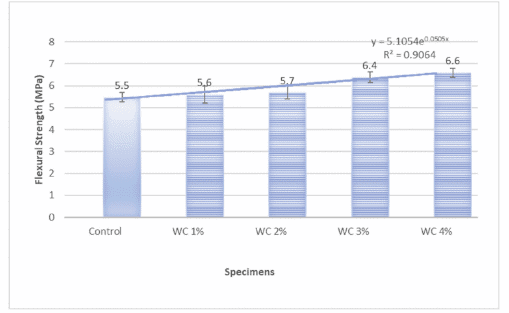

Figure?4.?Flexural?Strength?Variation?with?the?increase?in?WC?percentage.?

Rapid?Chloride?Permeability?Test?

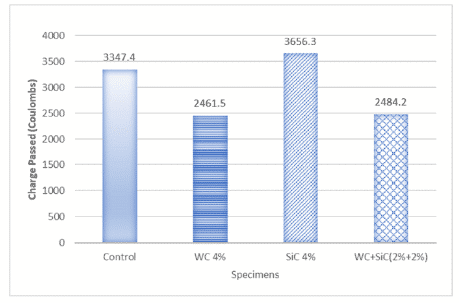

The permeability of concrete is the key characteristic to control other durability problems. Higher permeability is related to lower durability, higher corrosion potential and other durability problems. RCPT test is a standard test method to indicate the chloride permeability and corrosion possibility of steel. After obtaining the best results for 4% of single and mixed carbides, a rapid chloride determination was carried out for these concrete carbides.

Figure 5 depicts the RCPT results by comparing the average charges of the composite and ordinary concrete through the car. The test concluded that the minimum charge passed WC 4%.

Figure?5.?Rapid?Chloride?Permeability?Test?of?Specimens.?

The results show that WC has the greatest resistance to chloride ion penetration. When used alone or mixed, WC reduces the permeability of concrete composites. WC is very dense and does not allow ions to pass through. Therefore, even a small amount of WC can provide a barrier for ions to pass through the concrete. However, silicon carbide shows higher permeability. Hybrid carbide composites reduce permeability due to their synergistic effect and better density.

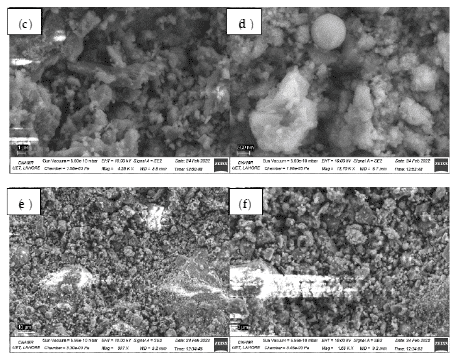

Field emission scanning electron microscope

Figure 6 shows the field emission scanning electron microscope images of control (a), wc4% (B – d) and sic4% (E, f) samples.

Fig 6.?FESEM?results?for?(a)?control?sample,?(b–d)?WC4%?sample?and?(e,f)?SiC4%?samples.?

In Fig. 10B, the acicular metallic luster under the hydration product shows the presence of WC whiskers. Obviously, the needle passes through a very fine crack to bridge the crack. WC does not show obvious ITZ, which may be the reason why the addition of WC leads to better strength. Tungsten carbide whiskers look similar to solid metals and have no obvious pores. WC also seems to attract hydration products. In Fig. 10d, a circle of white salt hydration products that may be formed at the end of the WC needle can be seen. Good interlayer and unclear ITZ show that WC has better compatibility with concrete, resulting in better strength. No obvious porosity will lead to low permeability.

Fazit

In this study, the effects of tungsten carbide (WC), one of the hardest materials on the earth, on the compressive strength, flexural strength and permeability of concrete were studied. Using tungsten carbide alone and adding it to 4% of the weight of cement in a mixed form to produce carbide concrete composites will be a very good choice.

The increase of the percentage of carbides in individual and mixed forms increases the compressive strength and flexural strength of concrete. With the increase of compressive strength, the compressive strength of WC concrete composite (i.e. 17%) is higher than that of SiC composite (the compressive strength increases by 6%). WC is especially suitable for pavement concrete.

When the dosage is 4%, the permeability of WC and hybrid composites is relatively low. FESEM images also verified the results. Obviously, both tungsten and carbide can improve performance and be compatible with concrete. However, hybrid carbide composites provide synergistic effects by improving mechanical strength, especially flexural strength, and reducing permeability.

Suggestions for the future

The properties of the composites are directly improved by adding 4%. This means that a higher percentage of tungsten carbide can be investigated. This work can be further extended to concrete composites to obtain other unique properties of their constituent carbides, including neutron shielding, bulletproof, electromagnetic radiation barriers for nuclear reactors and 3D printing. If positive results are obtained, it may pave the way for the production of cement and concrete with special properties.