For most guys working in the industry of metal machining, Cast iron must be a kind of familiar material.

What is cast iron? First of all, it’s a sort of ferro-carbon alloy that contains more than 2.11% of carbon and small amounts of Si, Mn, S, and P.

The mechanical properties of cast iron are lower than that of cast steel. But it has excellent castability, shock absorption, wear resistance and cutting machinability. The production process is simple and the cost is low. It is one of the most commonly used metal materials in engineering.

Classification of Cast Iron

The structure of cast iron is mainly Fe and Fe3C. Carbon exists in cast iron mainly in the form of cementite and graphite. Therefore, according to the different forms of carbon in cast iron, we can divide it into two categories:

1 white cast iron

C exists in the form of cementite (Fe3C), and the fracture is white. It is hard and brittle to cut. Mainly used as steel-making raw materials, high wear-resistant parts (rolls, ploughs)

2 grey cast iron

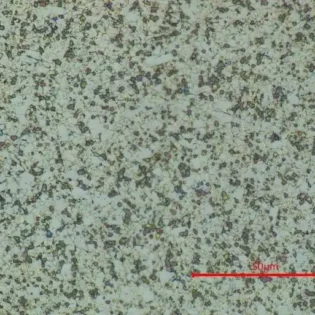

The existing form of C is graphite (G), and the fracture surface is gray-black.

Gray cast iron is the most widely used cast iron material with the best casting performance.

Graphite on gray cast iron can split the matrix. Therefore, the existence of graphite will reduce the mechanical properties of cast iron, leading to cast iron can not be forged. However, the existence of graphite also gives cast iron casting, shock absorption and wear resistance.

Graphite on gray cast iron can split the matrix. Therefore, the existence of graphite will reduce the mechanical properties of cast iron, leading to cast iron cannot be forged. However, the existence of graphite also gives cast iron casting, shock absorption and wear resistance.

Graphitization of Cast Iron

The process in which carbon atoms are precipitated from cast iron to form graphite is called graphitization. These graphites can be precipitated from liquids or austenite or obtained by decomposition of cementite.

For example, graphite in grey cast iron and ball-milled cast iron is mostly precipitated from liquid. The graphite of malleable cast iron is obtained by decomposition of cementite in white cast iron after long annealing.

If graphitization can be carried out adequately. Grey cast iron can be obtained, whereas white cast iron can be obtained. In a word, the type of structure of cast iron depends on the degree of graphitization.

Factors Affecting Graphitization

1.Alloy elements: C and S I strongly promoted, S strongly hindered, Mn hindered, P weakly promoted.

2.Cooling rate: Slow cooling is conducive to graphitization. Carbon precipitates in the form of G. Gray iron based on F is obtained. When the cooling rate is too fast, C precipitates as cementite to obtain white cast iron.

Types and Properties of Gray Cast Iron

According to the morphology of graphite in gray cast iron, we can divide it into:

Gray cast iron: graphite flake

Malleable cast iron: graphite is flocculent

Ductile Iron: Graphite Spherical

Vermicular graphite cast iron: graphite vermicular

1.Gray cast iron

Its properties depend on the body structure and graphite morphology. The fracture of graphite sheet on the steel matrix destroys the continuity and integrity of the matrix, making the compressive strength of gray cast iron similar to that of steel. Therefore, ordinary gray cast iron is widely used as parts under pressure load, such as bearings, machine tool fuselage and so on.

2. Malleable cast iron

It is cast from cast iron into white cast iron, and then annealed by graphitization at high temperature to decompose cementite into flocculent graphite. Although its plasticity and toughness are better than that of gray cast iron, it is still unable to be forged.

Because of its strength, plasticity and impact toughness, it can replace part of carbon steel.

3. Ductile Iron

Ductile iron has similar mechanical properties to steel and can be used instead of cast steel and forged steel. It is often used to manufacture wear-resistant parts with heavy load and complex stress, such as crankshaft, connecting rod, gear, spindle, etc.

4. Vermicular graphite cast iron

Vermicular graphite cast iron is made by adding proper amount of vermicularizing agent into molten iron. Its method and procedure are basically the same as that of ball-milled cast iron. The length of graphite sheet is relatively small, and the end of graphite sheet is relatively blunt. It is worm-like.

It is a new type of high strength cast iron material. Its strength is close to that of ball-milled cast iron, and it has certain toughness and high wear resistance. At the same time, it has the same good casting properties and thermal conductivity as gray cast iron.

Now it has been successfully used in high-pressure heat exchanger, cylinder and head of internal combustion engine, cylinder liner, ingot mould, hydraulic valve and other castings in high-rise buildings.