The ball mill consists of a metal cylinder and a ball. The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal force. At a certain height, it will automatically fall and impact and grind the material in the cylinder to grind the material. In addition, the agitation of the ball will evenly mix the materials.

Factors affecting ball milling efficiency, in addition to the structure of the ball mill. Mainly the rotation speed of the ball mill, the size and number of the grinding body, the volume of the object to be polished, the grinding medium and the grinding time.

1. the speed of the ball mill

When the ball mill rotates, the ball movement in the barrel may have three states (pic 8-1).

When the rotation speed of the grinding cylinder is not large, the ball loading amount is less, and the sliding state a will occur, which is called the sloping type. At this time, the ball has no stirring effect on the material, and only the ball has frictional effect on the material. Therefore, the mixing and grinding efficiency is extremely low.

When the rotation speed is high and the ball loading amount is large, the ball forms a drop type under the action of centrifugal force and starts rolling grinding b. At this time, there is both a turning action and a mutual friction between the ball and the material (grinding action), so the mixing and grinding efficiency is high.

When the rotation speed of the grinding cylinder is higher than a certain speed (critical speed), the sphere is not attached to the wall of the cylinder and cannot fall freely due to the large centrifugal force. At this time, the material is neither stirred nor broken.

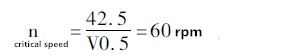

Obviously, the spherical motion is more satisfactory in the b state. When the ball is rotated against the Tang cylinder, the minimum speed is called the critical speed, and the critical speed n can be alculated by:

Wherein D is the diameter of the mill barrel (meter). Let D = 0.5 m, then

This is the critical speed of the 180 litre wet mill currently used in cemented carbide production.

To make the ball in the b state, the actual speed of the ball mill is usually 36 rpm.

2. the amount of ball loading

In order to make the ball in a rolling state, in addition to the rotation speed of the grinding cylinder, it depends on the amount of ball loading and the friction between the grinding body and the wall of the cylinder. At present, although the calculation formula of the limit ball loading amount can be theoretically derived, since the friction coefficient is difficult to measure, the ball loading amount is often determined empirically.

According to experience, the critical loading amount is about 40% to 50% of the volume of the grinding cylinder.

The ratio of the volume of the ball to the volume of the drum is called the filling factor. If the filling factor is less than 30%, the sphere is liable to be in a sliding state, and the grinding efficiency is low. If the filling factor is greater than 50%, the ball’s moment of inertia near the center of rotation is too small, which in turn reduces the grinding efficiency. A reasonable filling factor is 40-50%, and the grinding efficiency is maximum at this time.

3. the size of the ball

Grinding occurs by contacting the surface of the ball with the powder. Therefore, in the rolling ball mill, the grinding efficiency is increased as the ball diameter decreases. It has been proven that the highest grinding efficiency can be obtained with a small ball of .mm diameter. However, the ball diameter is too small to wear too fast, and it is also difficult to discharge due to the small gap of the ball. Therefore, the ball used in wet-grinding the mixture should not be too small or too large. In the production of cemented carbide, the ball of dia5-10 is mostly used for grinding WC-Co material, and the ball of dia 12-18 mm is mostly used for grinding WC-TiC-Co material. The use of cemented carbide balls increases the quality of the ball and reduces the contamination of the wet abrasive by impurities. The use of a small cylinder instead of a ball as the abrasive body has a higher grinding efficiency.

4. the amount of loading

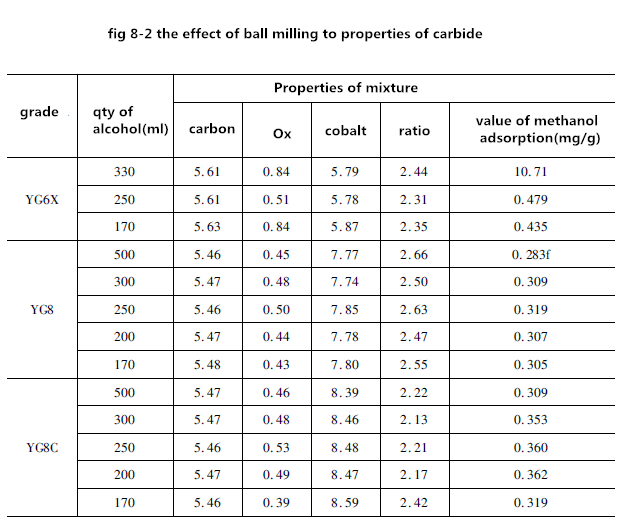

The amount of charge is usually expressed by the ratio of the ball to the ball (the ratio of the ball to the heavy material). The larger the ball to material ratio, the higher the grinding efficiency. But too high a ball ratio is unhelpful. Because the amount of charge is reduced when the filling factor is constant, it is bound to reduce the productivity of the set, and sometimes reduce the alloy properties (Figure 8-2). The ball ratio is usually selected from 2:1 to 5:1. In some cases, a large ball-to-batch ratio is used. For example, a wet-milled titanium carbide-based carbide bar can be used for 6:1. Because the volume of the mixture is large at this time. It seems that using the ball to material volume ratio to indicate the amount of charge will be more suitable. In theory, when the material just fills the gap of the ball, both the grinding efficiency and the production efficiency are ideal.

5.wet grinding media

As a wet grinding medium, it must have the following conditions and no chemical reaction with the mixture, no harmful impurities, low boiling point, volatile removal at around 100℃, small surface tension, no powder agglomeration, no toxicity, safe operation, Low prices are also one of the conditions to consider.

As the wet grinding medium, there are alcohol, acetone, gasoline, carbon tetrachloride, benzene, hexane and the like. The most widely used in production is alcohol, followed by acetone, hexane and the like.

The main function of the wet grinding medium is to disperse the powder agglomerates, which is advantageous for uniform mixing. In addition, it may be adsorbed on the defects of the powder particles, so that the strength of the powder particles is lowered, thereby facilitating the fracture.

The amount of wet grinding medium added is usually expressed by the liquid-solid ratio, that is, the number of milliliters of liquid added per kilogram of the mixture.

6.wet grinding time

Practice has shown that as the wet grinding time increases, the particle size of the powder becomes finer, but at the same time, the particle size composition range becomes wider, which increases the unevenness of the powder & does not cause the grain growth of the alloy after sintering. Uniformity increases.

For the two-phase WC-TiC-Co alloy, the grain size and properties of the alloy are significantly dependent on the wet grinding time (Fig. 8-4). In this case, it is easier to select the best wet grinding. time. However, for some other alloys, as shown in Figure 8-5), after a certain ball milling time, the average grain size of the alloy is no longer significantly reduced.

The effects of wet milling time on the properties of YT15 and YT5 alloys are listed in Table 8-2. It can be seen that after three days of ball milling, the strength of the alloy is slightly reduced, the hardness and coercive force and the cutting coefficient are slightly increased, and the amount of change is generally within the measurement error range. Therefore, too long ball milling time is unnecessary.

In summary, it is not currently possible to theoretically calculate the grinding time of different mixtures, but must be determined by experiments according to the requirements of the alloy.