Experienced experts in the processing field know that processing temperature and processing accuracy are closely related. This article will do a basic science popularization, which will help you understand that the processing temperature affects the processing accuracy from these four aspects.

01 processing temperature affects material properties

As we all know, materials will have thermal expansion and cold contraction. In precision machining, the problem of processing temperature must not be ignored! Temperature difference is the enemy of accuracy. If we don’t care about the important issue of processing temperature, how to discuss accuracy? Because most of the machine combination components are steel and cast iron, the shape and length will change according to the room temperature and the heat generated by the machine itself.

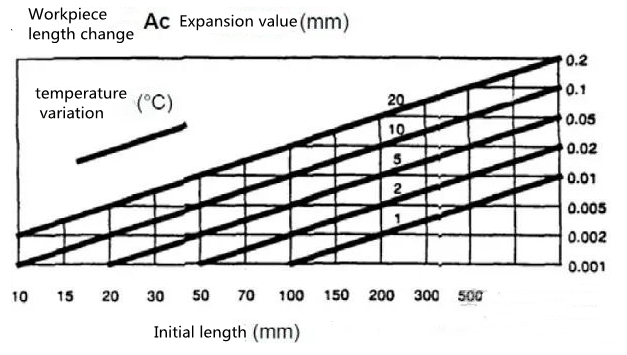

The specific amount of thermal expansion and cold contraction of materials depends on the change value of materials and processing temperature. The expansion coefficient table of steel and copper is provided below. For example, the linear expansion of steel is 12% per meter when the processing temperature changes by 1 ° C μ Change of M.

The expansion coefficient of steel is shown in the following figure:

Workpiece length: 200 mm

Processing temperature change: 10 ℃

Expansion value: 0.02 mm

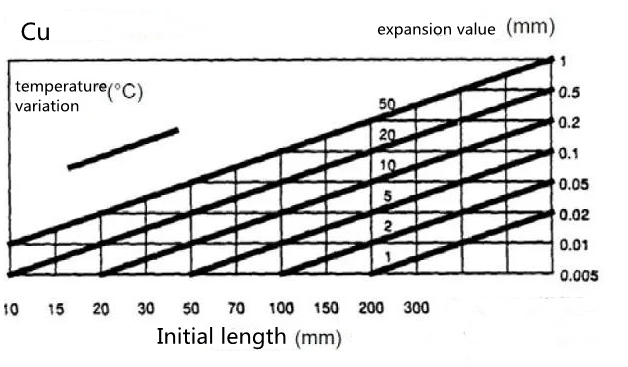

The expansion coefficient of copper is shown in the figure below:

Processing temperature change: 10 ℃

Expansion value: 0.05 mm

2Detection error caused by processing temperature

If the workpiece and the detection instrument and gauge used for detection are made of different materials, and the detection is not under the standard processing temperature, the deviation from the standard processing temperature of 20 ° C will always be an important factor in the detection error.

For example, if a 100mm long steel block gauge is heated to 4C, for example, with the palm processing temperature, it will appear 4.6 μ The length of M changes.

03 maintain stable processing temperature and facilitate precision control

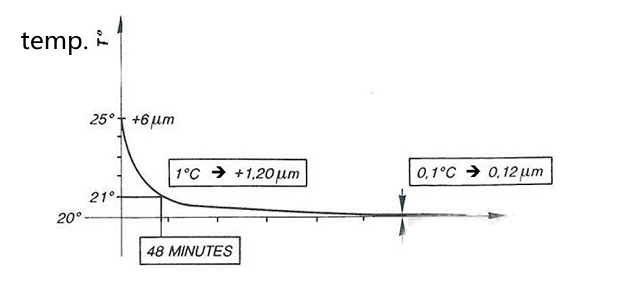

For a 100 x 30 x 20 mm steel part, the processing temperature decreases from 25 ℃ to 20 ℃. The size changes: at 25 ℃, the size is larger than 6 μ m. When the processing temperature drops to 20 ℃, the size is only 0.12 larger μ m. This is a heat stable process. Even if the processing temperature drops rapidly, it still needs a continuous time to maintain accuracy. The larger the object, the more time it takes to restore accuracy stability when the processing temperature changes.

Factories without precision machining experience often attribute the instability of precision to the accuracy of equipment when doing precision machining. And factories with precision machining experience know that this is the most basic common sense, and they will attach great importance to the environmental processing temperature and the thermal balance of machine tools. They know very well that even high-precision machine tools can achieve stable machining accuracy only under stable machining temperature environment and heat balance.

Maintaining thermal stability is an important concept that must be understood in precision machining. Some people may be confused about whether the processing temperature should be maintained at 20 ℃ or 23 ℃. In fact, the most important thing is to maintain the stability of a target value. The general requirement of the theory is 20 ℃, and the actual workshop is generally 22-23 ℃, and the fluctuation of the processing temperature can be strictly controlled.

3 feedback of processing temperature on precision and accuracy

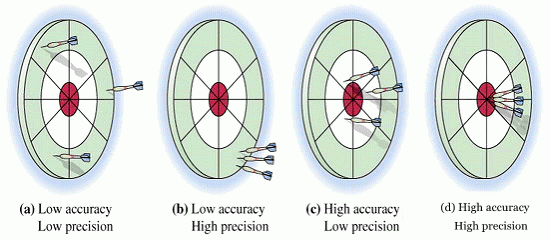

Generally speaking, machining accuracy can be divided into precision and accuracy. The following figure is an intuitive illustration.

Precision

It refers to the reproducibility and consistency between the results obtained by repeated determination with the same spare sample. It is possible that the precision is high, but the accuracy is not high. For example, the three results obtained by measuring the length of 1mm are 1.051mm, 1.053 and 1.052 respectively. Although their precision is high, they are not accurate.

Accuracy

It refers to the closeness between the measured result and the true value. The high accuracy of measurement means that the system error is small. At this time, the average value of the measured data deviates less from the true value, but the data is scattered, that is, the size of the accidental error is not clear.

Relationship between precision, accuracy and processing temperature

Generally speaking, if the processed parts are precise but not accurate, it is likely that the processing temperature in the workshop fluctuates greatly, resulting in large discreteness of accuracy; If the processed parts are more accurate but not precise, it is likely that the processing temperature in the workshop fluctuates little, but deviates greatly from the standard processing temperature; It is neither precise nor precise, which means that the workshop processing temperature deviates greatly from the standard processing temperature and control requirements.

4 preheating of forgotten machine tools

The factory uses precision CNC machine tools for high-precision machining. Do you have such experience: every morning, when you start the machine for machining, the machining accuracy of the first piece is often not good enough; The accuracy of the first batch of parts processed after a long holiday is often very unstable, and the probability of failure in high-precision processing is very high, especially the position accuracy.

Only under the stable processing temperature environment and heat balance state, the machine tool can obtain stable processing accuracy. In the case of high-precision machining production after starting up, preheating the machine tool is the most basic common sense of precision machining.

The machining accuracy of the machine tool in the state of long-term shutdown and the state of thermal balance is quite different. The reason is that the machining temperature of the spindle and each moving axis of the NC machine tool is relatively maintained at a fixed level after running for a period of time, and the thermal accuracy of the NC machine tool tends to be stable with the change of machining time, which indicates that it is very necessary to preheat the spindle and moving parts before machining.