At present, stainless steel is widely used in industry such as aerospace, power generation equipment manufacturing, construction and food. As a typical hard-to-machine material, stainless steel has the defects of severe hardening during processing, high cutting temperature and easy adhesion of chips. Due to the above characteristics of stainless steel, common problems such as accelerated wear of the tool, poor integrity of the machined surface, and difficulty in chip removal are likely to occur during the machining process of STS, which seriously affects the processing quality, production cycle and processing cost of those material parts containing STS. Meetyou carbide tech depart analyzes and summarizes the difficulties in processing stainless steel materials, and provides solutions with specific measures for stainless steel cutting and typical products for your reference.

Reasons why stainless steel materials are difficult to process

1. High temperature strength and work hardening tendency

Compared with ordinary steel, stainless steel has medium strength and hardness. However, it contains a large amount of elements such as Cr, Ni, and Mn, and has good plasticity and toughness, high temperature strength, and high work hardening tendencym which therefore result in the cutting load. In addition, in the austenitic stainless steel during the cutting process, some carbides are precipitated inside, which increases the scratching effect on the cutter.

Fig.1. Common stainless steel’s temperature strength

2.Large cutting force is required

Stainless steel has large plastic deformation during cutting, especially austenitic stainless steel (the elongation exceeds 1.5 times that of 45 steel), which increases the cutting force.

3.chip and tool bonding phenomenon is common

It is easy to form built-up edge during cutting, which affects the surface roughness of the machined surface and easily causes the surface of the tool to peel off.

4. the chip is easy to curl and break

For closed and semi-closed chip cutters, chip clogging is easy to occur, resulting in increased surface roughness and tool chipping

Fig.2. The ideal chip shape of stainless steel

5. the large coefficient of linear expansion

It is about one and a half times the linear expansion coefficient of carbon steel. Under the action of cutting temperature, the workpiece is prone to thermal deformation and affects the dimensional accuracy.

6. small the thermal conductivity

Generally, it is about 1/4~1/2 of the thermal conductivity of medium carbon steel. The cutting temperature is high and the tool wears fast.

Auswahl des Werkzeugmaterials

1. Tool materials with high hardness, toughness and heat resistance, and chemical affinity with stainless steel should be selected.

2. When using high-speed steel to process STS, high-performance high-speed steel such as W2Mo9Cr4VCo8, W6Mo5Cr4V2Al, W10Mo4Cr4V3Al, etc. should be used.

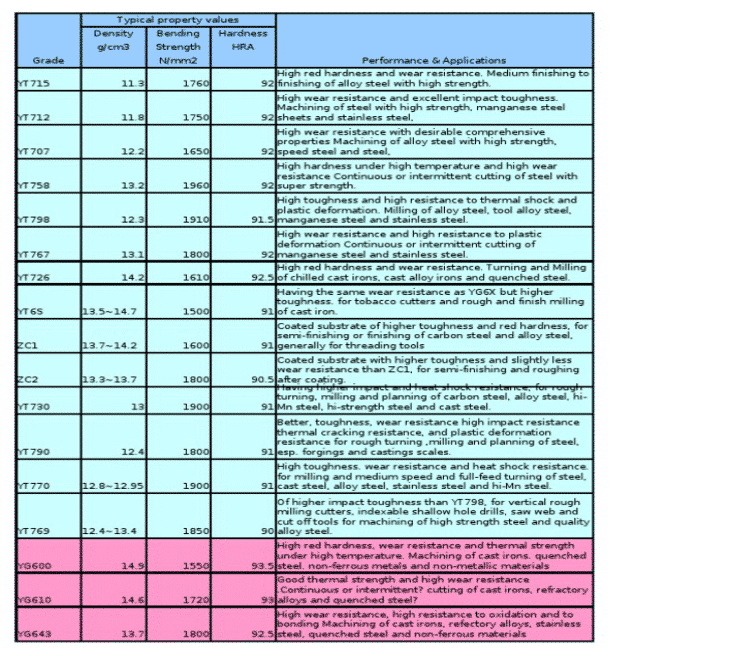

3.When using cemented carbide, it is not advisable to use YT-based alloys, and it is preferable to use Ta (Nb)-containing YW or YG tungsten-cobalt (ISO M, K) alloys. Such as YS2, YG3X, YG8W, YG6A, YG6X, YG643, YG813, YW3Y, YG8N, etc.

It is well known that the cutting performance of tool materials is related to the durability and productivity of the tool. The processability of the tool material affects the manufacturing and sharpening quality of the tool itself. It is advisable to choose tool materials with high hardness, good adhesion resistance and toughness, such as YG type hard alloys.Using YT type hard alloys for SUS is not a good choice, especially in processing 1Gr18Ni9Ti austenitic stainless steel. YT type hard type should be absolutely avoided. Alloys, because titanium (Ti) in stainless steel and Ti in YT-based cemented carbides produce affinity, the chips easily carry away the Ti in the alloy, which leads to tool wear. Production practice stat shows that the processing of stainless steel with YG532, YG813 and YW2 produce good processing results.

Because cemented carbide has better heat resistance and wear resistance than high-speed steel, tools made of hard alloy materials are more suitable for stainless steel cutting. Tungsten-cobalt alloy has good toughness. The tool can be made with a larger rake angle and a sharper edge.So in general, it is suitable to process stainless steel with a tungsten-cobalt alloy. Especially in the case of rough machining and interrupted cutting with large vibration, tungsten-cobalt alloy blades should be used. It is not as hard and brittle as tungsten-cobalt-titanium alloy, and it is not easy to chip. While Tungsten-cobalt-titanium alloy has good red hardness and is more wear-resistant than tungsten-cobalt alloy under high temperature conditions, but it has high brittleness and is not resistant to impact and vibration. Thus, it’s generally used as a stainless steel finishing tool.

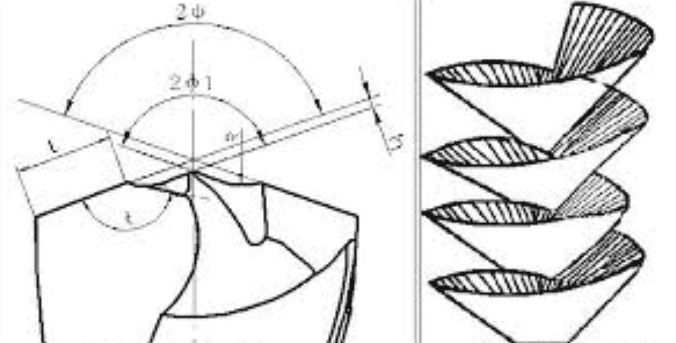

Fig.3. Comparison of YT grade and YG grade

4.The coatings of cemented carbide may be CA15, CA25, YBM151, YBM251, YBM351, YBG202, YBG252, YBG302, CN251, YB425, ZC05, ZC07, ZM10 and the like.

The classic coating is a TiAlN or AlCrN coated tool. TiAlN coating has excellent properties such as high hardness, high oxidation temperature, good thermal hardness, strong adhesion, low friction coefficient and low thermal conductivity. Since the Cr element has a higher melting point than the Ti element, the coating company has developed an AlCrN coating in which Cr is substituted for Ti. Compared with TiAlN, the high temperature oxidation temperature of AlCrN can be significantly improved, the friction coefficient is smaller, the chip removal ability is stronger, but the hardness is slightly reduced.

Fig.4 The comparison of hardness of 3 different coating material

For cermet, YNG151 can be used. For coated cermet YNG151C can be used.