(1) To reduce the alloy’s sensitivity to sintering temperature fluctuations and carbon content changes, and to prevent the uneven growth of carbide grains;

(2) To change the phase composition of the alloy, thereby improving the structure and properties of the alloy.

This paper reviews the effects of adding rare earth elements, metals, and metal carbides to cemented carbides on their properties.

The Effect of Adding Rare Earth Elements on Carbide Properties

Rare earth elements are the 15 lanthanide elements with atomic numbers ranging from 57 to 71 in the third subgroup of the Mendeleev periodic table, plus scandium and yttrium, which have similar electronic structures and chemical properties, totaling 17 elements. Rare earths are known as the “treasure trove” of new materials and are a group of elements of particular concern to scientists worldwide, especially material experts. The following sections discuss the effects of adding rare earth elements on the hardness, bending strength, and grain size of cemented carbides.

1.1 Hardness

Whether the addition of rare earths has a significant effect on the hardness of the alloy is an issue of concern. The influence of yttrium and lanthanum on WC-TiC-Co cemented carbides is not significant, but different rare earth elements have different trends; however, the hardness of alloys with Nd or Ce added, regardless of the content, is slightly higher than that of the untreated alloys, with an average increase of 0.3 HRA units. For YG6 alloys, the addition of mixed rare earths results in a decrease in hardness to varying degrees when the content reaches 1%; for YT? alloys, the hardness remains largely unchanged or slightly increased with the addition of La or Y.

1.2 Bending Strength

Data shows that adding a certain amount of rare earth elements to the alloy can increase its bending strength. After the addition of rare earth oxides, the strength of the alloy is improved due to the dispersion strengthening of nickel by the rare earth oxides. When the content of rare earths is 1.2% to 1.6% of the binder metal content, the bending strength of the alloy reaches its maximum value; after adding mixed rare earth oxides equivalent to 0.25% to 1.00% of the binder mass fraction, the bending strength of the WC-8%Co alloy is improved to some extent. When the addition amount is 0.25% to 0.50%, the bending strength can be increased by 1.5%, but excessive addition of rare earths will lead to a decrease in bending strength.

1.3 Grain Size of Carbides

A large number of literature reports have been published on the effect of rare earths on the WC grain size in cemented carbides, but there is no unified conclusion to date. Regardless of the type of rare earth element added, the carbide grains in the alloy are finer than those without additives, and as the amount added increases, the refinement becomes more pronounced, and the grain size of the rare earth element-added alloy appears more uniform than that of the untreated alloy; studies have shown that the addition of trace rare earth elements does not affect the particle size of tungsten carbide and the binder phase.

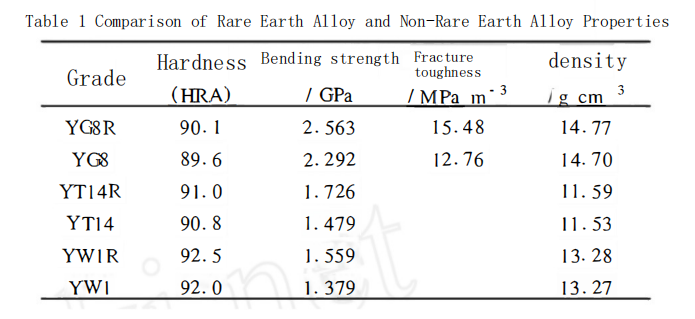

Through extensive observation of the WC grain size and microstructure of WC-Co-TiC-TaC with rare earths and WC-Co with rare earths alloys, it is believed that the effect of rare earths on the WC grain size of cemented carbides is determined by two refinement effects and one growth effect. Table 1 shows the comparison of properties between rare earth alloys and alloys without rare earths.

2 The Effect of Adding Metals on the Properties of Cemented Carbides

Commonly used metal additives include chromium, molybdenum, tungsten, tantalum, niobium, copper, aluminum, and others. Except for copper and aluminum, all of these can form carbides. Therefore, the change in the carbon content of the alloy must be considered when adding these metals.

2.1 Adding Noble Metals

Sintered cemented carbide products with added noble metals such as Ru, Rh, Pd, and Re exhibit high wear resistance and corrosion resistance and can be used in corrosive and abrasive media. Noble metals do not form carbide phases and exist in the binder metal as solid solutions. Ru and Re cause the formation of a substructure in the binder phase of the cemented carbide. Alloying sintered cemented carbides with noble metals can increase the microhardness and elastic modulus of the binder phase, while also improving the bending strength, compressive strength limit, and yield point of the sintered cemented carbide as a whole.

2.2 Adding Copper

The addition of a small amount of copper to alloys used in mining can both increase the strength of the alloy and improve its impact toughness. Research results indicate that after adding a small amount of copper to the WC-13% Fe/Co/Ni alloy, the hardness of the alloy slightly decreases, but the bending strength is significantly improved. When the copper content is around 0.8%, the alloy exhibits the best performance. Moreover, copper also has the effect of refining and spheroidizing WC grains.

2.3 Adding Alkali Metals

Alkali metals can promote the growth of WC grains, but their effect is limited by other factors. For instance, in the presence of silicon, sodium actually refines the WC grains; whereas if sodium is present during the carbonization process, the WC grains will become finer. Adding industrial-grade Li?CO? with a purity of 98% to 99% to the alloy results in a cemented carbide with coarser average grains, clear and well-defined grain edges, and high bending strength.

2.4 Adding Aluminum

The effect of adding a small amount of Al on the properties and structure of the WC-13% Fe/Co/Ni cemented carbide shows that the addition of a small amount of aluminum can refine the WC grains. While the hardness of the alloy increases by 2 to 3 HRA, the bending strength of the alloy can be improved by 100 to 200 MPa. When the amount of Al added exceeds 0.8%, the bending strength of the alloy decreases, which is due to reasons such as the enrichment of martensite at the phase interface and the relative change in the amount of γ phase. Table 2 shows the effect of metal additives on the properties of the alloy.