1.What is hot isostatic pressing?

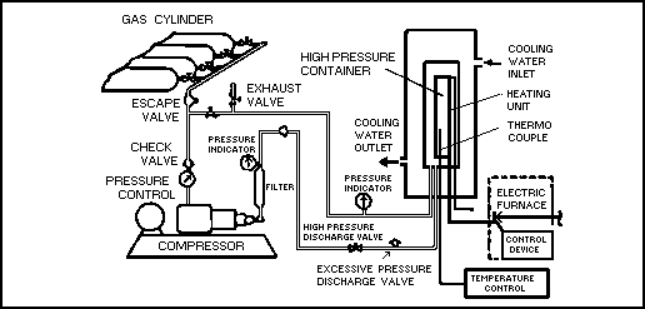

HIP is the abbreviation of Hot Isostatic Pressing, which is a isotropic compression and compacting technology of objective material by use of high-temperature and pressure gas as a pressure and heat transmitting medium(hundreds to 2000 ℃ and an isostatic pressure of tens to 200 MPa). Argon is the most commonly used pressure medium.

It was invented in USA in 1950s and has been used for forming, sintering, jointing and removal of defect of various materials such as metal, cemented carbide and ceramics.

Fig.1 shows the appearance and Fig.2 shows the configuration of HIP equipment.

2.Difference between hip and hot pressing

Hot pressing is very similar to hip. Milling, forging and extrusion are also applicable to high temperature and high pressure, but unlike hot isostatic pressing, they are not applicable to isostatic pressing.

The most obvious difference between hip and hot pressing is that hip uses gas pressure to apply isostatic pressure to materials, while hot pressing only applies uniaxial pressure.

Compared with hot pressing, hip can provide a material shape that is not much different from the initial shape after pressing. Even after changing the shape, the material can maintain its original shape and is relatively less restricted by product processing. By making full use of these characteristics, hip has been applied in various fields.

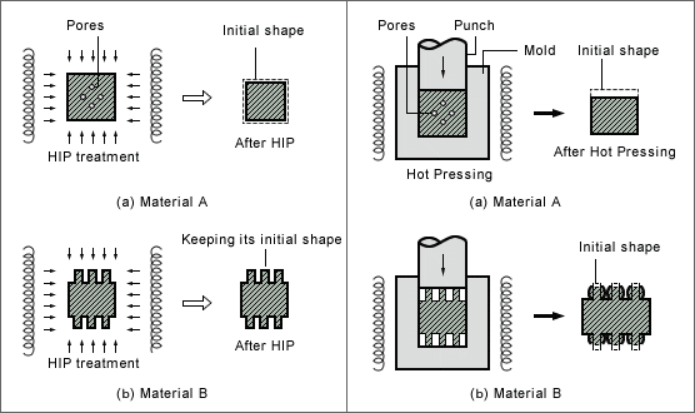

In order to clearly explain the difference between hot isostatic pressing and hot pressing, we assume that hot isostatic pressing or hot pressing is applied to material a (metal with holes inside) and material B (metal with uneven ends), respectively.

As shown in Fig. 3, if hip technology is used, material a will shrink and maintain its initial shape until the internal pores disappear and are combined due to diffusion effect. And the material B will not change its shape at all because a uniform pressure is applied to the uneven edge.

As shown in Fig. 4, in the case of hot pressing, the material a will appear the same phenomenon as hip. The material B cannot maintain its initial uneven shape because the pressure is only applied to the convex portion. Material a and material B will have different final shapes after hot pressing, depending on the shapes of the dies and punches used. The application of hot pressing technology to manufacture large-scale products and molded parts is due to the non-uniformity caused by the friction with the mold and the limitation of temperature and size in the deformation process.

3.Hip application mode

Materials need to be treated according to the situation. The most typical methods include “capsule method” and “no capsule method”.

As shown in the right figure, “capsule method” is to seal the powder or the main body molded from the powder in an airtight capsule and empty the capsule before hip.

This “capsule method” can provide high density even for materials that are difficult to be sintered by ordinary sintering technology. Therefore, it is most commonly used in the pressure sintering process of powder materials. It is also used for diffusion bonding or high-pressure impregnation carbonization of different types of materials.

The following table summarizes the main materials of the capsule free method and hip treatment temperature / pressure.

If the pores in the material are isolated, closed, and not connected to the material surface, these pores may be squeezed and eliminated by hip treatment. On the other hand, even after hip treatment, the opening connected to the material surface is not squeezed. Therefore, hip treatment of materials with closed holes can provide high density of the entire material.

This material does not require capsules for hip, which is called the “capsule free method”. This is used to remove residual pores on sintered parts, remove internal defects of castings, and repair parts damaged by fatigue or creep.

4.HIP concrete applications

Hip is widely used in the following fields:

(1) pressure sintering of powder

(2) diffusion bonding of different types of materials

(3) remove the residual pores in the sintered parts

(4) removal of internal defects of castings

(5) repair of fatigue or creep damaged parts

(6) high pressure immersion carbonization method

Let’s take the production of cemented carbide as a specific example of applying hip technology.

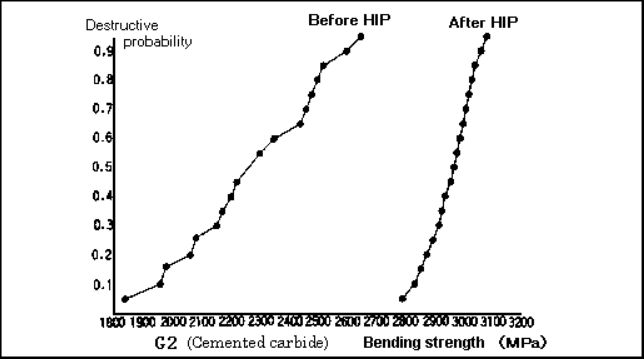

Cemented carbide is inferior to steel and other metals in toughness, and is very vulnerable to defects such as coarse particles and pores. In order to make full use of the natural characteristics of these materials, it is necessary to remove these internal defects, and hip is the most effective means to eliminate these defects.

Since the liquid phase of a metal such as cobalt is used as the binder phase when sintering the cemented carbide, the ordinary sintered body can be compacted to a density close to the theoretical density. However, there are still fine pores in the sintered body, which play a fatal role in the cemented carbide and break under the pressure that can be borne under normal conditions. The purpose of hot isostatic pressing is to completely eliminate some pores in the sintered body.

Table 1 shows the changes of mechanical properties under hot isostatic pressing, and Fig. 3 shows the Weibull diagram of bending strength before and after hot isostatic pressing.

Table 1 Effect of HIP treatment on mechanical properties of cemented carbide

| Before HIP | After HIP | |

| Relative density [%] | nealy 100 | nealy 100 |

| Hardness [HRA] | 91.0 | 91.0 |

| Bending strength [Mpa] | 2450 | 2940 |

| Fracture toughness [Mpa·m1/2] | 10 | 10.5 |

As shown above, the density and hardness of cemented carbide are not changed by HIP treatment. However, by the removal of fine pores, the bending strength is largely improved and the dispersion in strength becomes very small to increase reliability.

OU ON PEUT TROUVER LES REFERENCES DE CET INFORMATIONS MERCIII

Hello HAFSA,

Thanks for leaving a comment on our blog post.

If you have any questions, you can email us at [email protected].

Best regards,

Meetyou Carbide

Leave a Reply

Your email address will not be published.