In water-cooled engines, the cylinder head has internal cooling water passages. These passages are connected to corresponding cooling water passages in the cylinder block. This circulation of coolant helps in cooling the high-temperature components such as the combustion chamber.

Characteristics of Engine Cylinder Head Structure

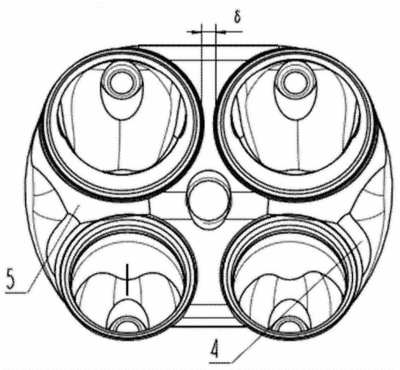

The structure of an engine cylinder head includes the main body, which is equipped with intake ports, exhaust ports, combustion chambers, and a camshaft chamber. The bottom surface is fitted with cylinder liners and is fastened and securely attached to the cylinder block using screws. Its main features are as follows:

1Sufficient Strength and Hardness: The cylinder head is designed with adequate strength and hardness to withstand the gas pressure and thermal stresses during engine operation. Equipped with a base to house the valve train mechanism, it ensures that the cylinder head can function safely under the influence of gas pressure and thermal loads.

2Hexahedral Shape: The majority of cylinder heads have a hexahedral shape, featuring multiple openings and being relatively thin. The machining process for cylinder heads can involve numerous intricate features, and the maximum number of machining processes can reach up to 100. The thinnest sections in cast cylinder heads can be as thin as 4.5mm.

The Rough Machining Process of Engine Cylinder Head

1First of all, cylinder heads are generally made of gray cast iron or alloy cast iron. In recent years, aluminum alloy cylinder heads have also been widely used. However, aluminum alloy cylinder heads are prone to deformation during use due to their lower stiffness.

2When constructing the cylinder head blank, it is essential to use skilled casting techniques and manufacturing machines for casting units. During the mass production of engine cylinder heads, emulsification flushing is carried out to reduce overheating and burning of the tools. This process also facilitates the removal of metal chips generated during machining and cutting.

3Finally, in the machining process, it is crucial to ensure uniform cooling of the casting. Neglecting this aspect can lead to surface looseness in some parts of the rough castings. It is essential to continuously monitor the pouring temperature to avoid failures in the cylinder head. Therefore, during the rough machining of the engine cylinder head, attention should be paid to each step, ensuring correct and diligent operations to guarantee the coordination of the cylinder head’s components and prevent various defects.

The Difficulties and Precautions in the Machining Process of Cylinder Head.

Flat Machining Process

The requirements for flat machining processes in cylinder head production are extremely strict. Before proceeding with the machining of the flat grooved cam, it is necessary to inspect it repeatedly from top view and side view and then establish the tool path mode.

The spiral downward cutting method is adopted because this method does not cause vibrations that could affect the workpiece and also helps protect the cutting tool. After the cylinder head component is completed, it should not be quickly removed because the production line is still in a high-temperature state, and premature removal could lead to burns on hands and workpiece deformation. We must wait for the workpiece temperature to dissipate before taking measurements to ensure accurate workpiece dimensions, and then make appropriate adjustments based on the wear of the radius and length.

Furthermore, during flat machining, it is crucial to choose the appropriate cutting position. Selecting the wrong cutting position can result in the entire cylinder head being scrapped.

High-Precision Hole Machining

During mechanical machining processes, there are instances where high precision and concentricity are required for certain positions. In such cases, high-precision hole machining is performed on the components. Using the center through-hole’s center as the reference coordinate, a positioning datum is established. The requirement is for the hole’s center to coincide with the extension of the center through-hole’s diameter. The coordinates for the first hole are determined on the machining center, and then drilling is carried out with the appropriate diameter.

After drilling is completed, measurements are taken to check for any errors, ensuring that the actual hole positions align closely with the ideal positions. Deviation data should be kept within 2mm, and a polishing tool with a finishing edge is used to smoothen the holes. For the high-precision machining of small holes, the axis alignment and perpendicularity to the bottom should be maintained within 0.03mm. Special tooling with front-end supporting seats is used to ensure greater accuracy when creating small holes.

Machining of Cylinder Head Valve and Guide Holes

This part of the machining process directly affects the engine’s performance. During engine operation, the combustible gas is compressed in the cylinder head’s combustion chamber before ignition, resulting in high temperatures in the valves. Therefore, the cylinder head valves must be able to withstand high thermal loads and possess good wear resistance. Additionally, to ensure the coaxiality tolerance of the valve seat and guide hole bottom, it is essential to maintain stable tolerance data and choose the correct position for the positioning datum.

As a result, in practical work, special composite tools are used, and the processing is carried out in three steps: drilling, semi-fine boring, and fine boring. Among these steps, fine boring is a critical process. To enhance the toughness of the slender boring bar, most boring bars are made of hard alloy material. Hard alloy boring bars have about three times greater elasticity than steel, providing better support.

During the final precision machining, in order to ensure high accuracy and reduce positioning errors, the adoption of pinhole positioning is promoted. Additional processing stations are added, and after the completion of valve and guide hole bottom machining, professional personnel further inspect the mechanical safety and determine the position data of the bottom holes.

Burrs in the Cylinder Head Machining Process

In the cylinder head production and machining process, burrs can be roughly categorized into four types: internal hole burrs, bore burrs, crossover burrs, and edge burrs.

The formation of burrs is caused by the squeezing action of the cutting tool on the cylinder head during the machining process, resulting in excess material beyond the original machining thickness at the edge being removed, leaving behind residual material. Dealing with burrs can be challenging because their positions differ on each component.

One method to remove burrs is by using water jet cutting. High-pressure water jets are used to physically impact and flush the bottom of the cylinder head’s internal holes and difficult-to-clean areas. The ease of high-pressure water jet flushing depends on the hardness of the burrs. When the burr hardness reaches about ten micrometers, the required pressure for the high-pressure water jet is below 30MPA. However, when the burr hardness increases to over one hundred micrometers, higher pressure might be needed for the water jet to effectively cut through the burrs at their roots. The combination of high-pressure water jet action and cutting can completely remove the burrs efficiently and in an environmentally friendly and energy-saving manner.

Conclusion

In conclusion, the engine cylinder head, as a critical component of the engine, needs continuous improvement in quality. During the machining and processing of the cylinder head, attention should be given to detail, avoiding scratches on the mating surfaces of the cylinder head. In subsequent machining processes, it is important to inspect and ensure precise positioning of the exhaust side. By implementing a rational and safe engine cylinder head machining process, the quality of the engine cylinder head can be effectively ensured.